CNC router is an automatic processing machine tool with numerical control system, which can automatically cut, engrave, mill, drill, groove, and slot different materials. It can be used for cutting and engraving 2D or 3D engraving of various materials. And it can produce very precise and complex shapes and contours by machining materials with tools. CNC routers can process a variety of materials, and has very wide application industries. Therefore, more and more consumers are beginning to worry: how can I buy a CNC router with high cost performance? My suggestion is that we should not only consider the CNC router price, but also pay attention to the performance of the CNC router machine and whether it can do our job well.

So do you really choose an engraving machine? How to buy a suitable CNC router for sale? Today, Blue Elephant will take you on a journey to select the best suitable CNC router.

Top 3 Best selling CNC routers

Don't count on that buying a CNC router machine can do all the different jobs. Manufacturers divide CNC routers into various specifications and types in order to deal with various processing tasks. For example, if you buy a EPS/foam CNC router to engrave two-color boards, or buy a large CNC router to engrave a stamp, both will cause huge waste. Similarly, if you buy an advertising small CNC router machine to make large molds, you may not be able to get the effect you want at all. Therefore, we have to choose different types of CNC routers according to our different needs. So what are the types of CNC router machines? Please read below, I will give you a brief introduction.

Wood CNC router

The first and most popular CNC router type is undoubtedly the wood CNC routers. Among them, the most basic and cheapest are 3 axis CNC routers; the highest-end and most expensive are 5 axis CNC routers, and the most cost-effective are 4 axis CNC routers. The wood CNC routers are commonly used in the engraving, cutting, drilling, milling, and other processing methods of wooden furniture such as cabinets, wardrobes, tables, chairs, and screens. If your workshop specializes in wooden tables and chairs, then you will need to add a rotary device to your wood CNC router for machining cylindrical materials. This kind of CNC router is also called rotary axis CNC router. If you need to engrave more different and complex patterns on the plate, you can choose a multi-head CNC router or ATC CNC router to process more work pieces at the same time.

Our country has a long history of stone processing and engraving. And stone engraving is one of the most important culture inheriting method. For example, stone tablets are strong, corrosion-resistant, and easy to preserve for a long time. Now with the development of numerical control technology. Stone CNC routers gradually replaced manual engraving method. CNC engraving machine for stone is a high-tech automatic computer-controlled engraving equipment, which can engrave calligraphy and painting on natural stone, glass, and ceramics. It can meet the requirements of personalized home decoration and tooling art design, and can be used as advanced carving processing equipment for decoration companies, handicraft industries, tombstone industries, and ceramic companies. The stone CNC routers can not only save labor costs, but also has high engraving efficiency, and has become a powerful tool for the new generation of stone manufacturers.

In addition to the above several wood CNC routers and stone CNC router, EPS/foam CNC routers are also very popular among customers. The foam allowance used in traditional hand-made automotive mold castings is very uneven, which has a great impact on the efficiency of mold processing. And the phenomenon of missing parts occurs from time to time, which affects the overall quality and production cycle of the mold. EPS Styrofoam CNC routers performs full 3D CNC machining on the foam type, which greatly improves the quality of the casting parts of the mold and shortens the production cycle of the mold.

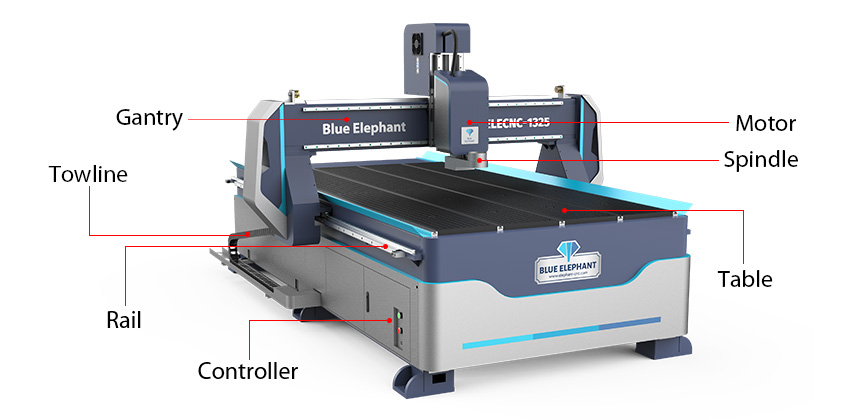

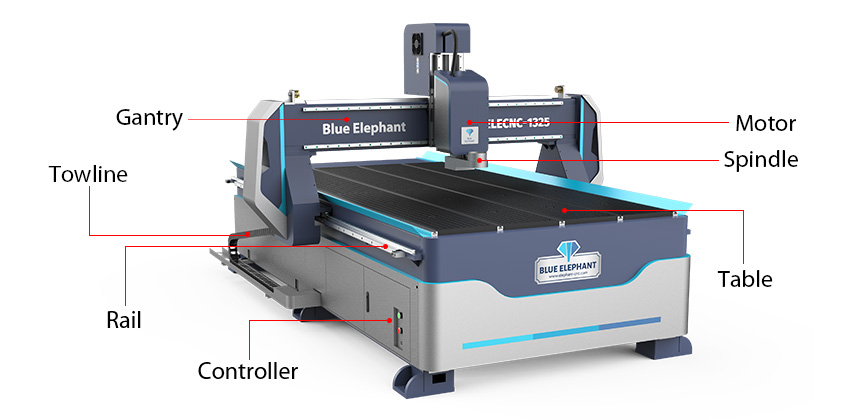

CNC router Kits

CNC router spindle

CNC spindle is the core CNC router bit for CNC routers. To some extent, the spindle type, power, and brand are factors that affect the CNC router quality. First of all, CNC router spindle can be divided into two main types- water cooling spindle and air cooling spindle. Second, according to different processed materials, the CNC router spindle power will vary. For example, the stone CNC router spindle power usually ranges from 3.0kw to 7.5kw; the woodworking CNC router has a spindle power of 2.2kw to 4.5kw; and the spindle power of advertising CNC router is from 1.5kw to 3.0kw. Third, the domestic CNC router spindles and imported CNC router spindles are also very different in the quality and price. Here are the top 3 CNC router spindles for sale.

Changsheng water cooling spindle

This water-cooled spindle is mainly known for the stable quality and high cost performance. It has the advantages of high speed, high precision, and large output power. The speed is about 24000rpm/min. It is widely used in turning, grinding, drilling, milling, etc.

HQD air cooling spindle

It is built by high quality aluminum to ensure the long service life of the CNC router tool. In addition, the main shaft adopts ceramic ball bearings, which ensures the high speed and high machining accuracy. Besides, it is cooled by fan, and it can be used without directly connecting the water tank, water pipe, and water pump to the inverter. Therefore, it has the advantages of low cost, convenient use, and simple operation.

HSD water cooling spindle

It has the features of good heat dissipation, low noise, long service life, and high precision. All parts used in the HSD spindle are strictly inspected and of high quality to ensure high machining accuracy. After being put into the market, it has been unanimously approved by users.

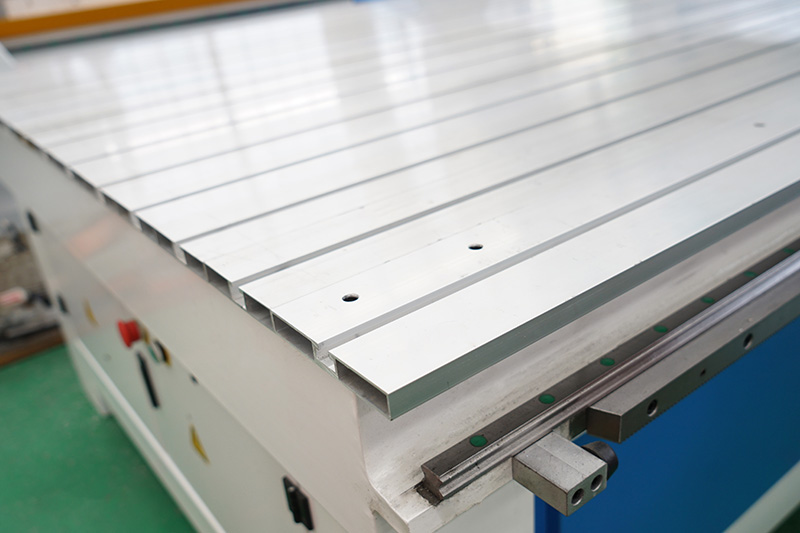

CNC router table

In fact, the most intuitive understanding is the CNC router table, including the size and material. The more common sizes on the market are CNC router table 2×3, CNC router table 4×4, CNC router table 4x8, and CNC router table 5×10. Of course, there are also smaller or larger CNC router table sizes, which can be determined according to clients ask for adjustments and customization. In addition, depending on different processing requirements, the material of the CNC router table will also be different. For example, aluminum CNC router tables are generally selected for stone materials, and vacuum CNC router tables are selected for woodworking. Below I will briefly take you to understand the main types of CNC router tables and their advantages. Hope to give you some help.

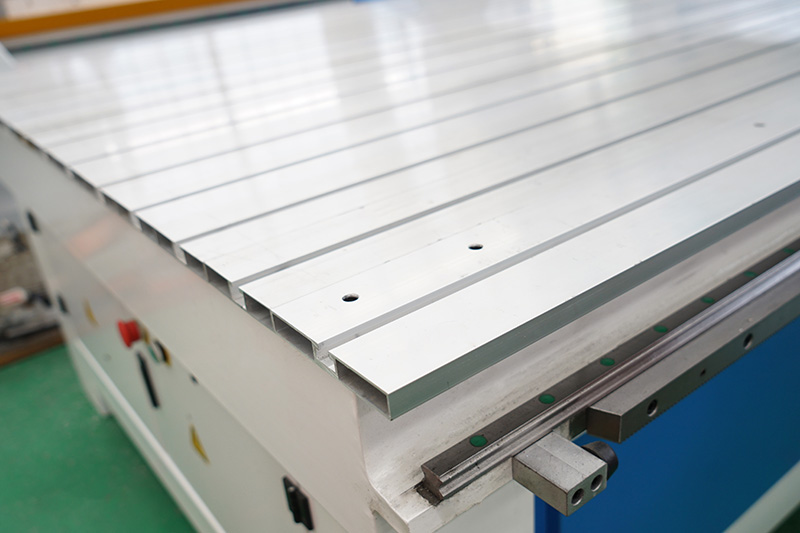

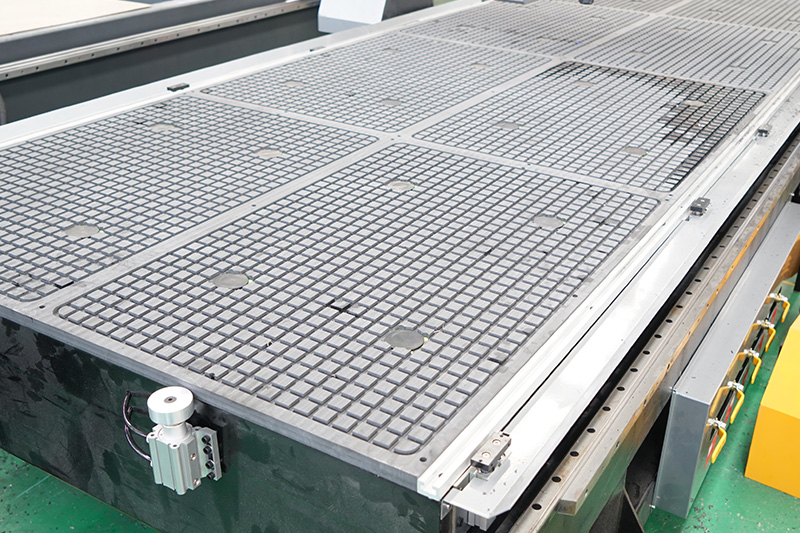

CNC router tables are mainly divided into aluminum working table and vacuum working table.

T-slot aluminum CNC router table

This CNC machine table is mainly used with clamps. It is suitable for processing flat relief, handicraft processing, hollow partition, screen, and other home decoration. But it is not suitable for quantitative production, especially the panel furniture production. And because of its high quality and low price, it is deeply loved by customers.

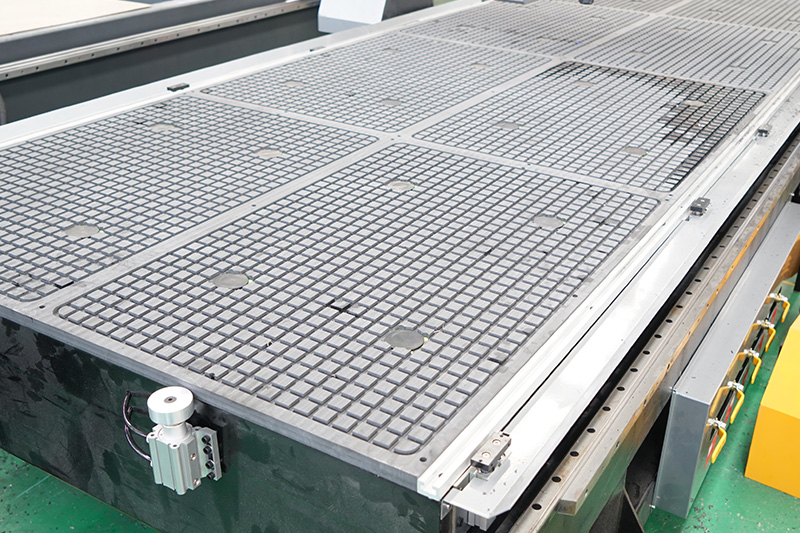

Vacuum CNC router table

It often uses a vacuum pump to fix the material. When the worker puts the plate on the vacuum table, the processed material can be firmly adsorbed by the negative pressure of the vacuum pump. And the whole process takes less than 10 seconds, which can greatly improve work efficiency.

Secondly, the vacuum CNC router table is divided into multiple areas, such as four zones, six zones, or eight zones. The larger the CNC machine size, the more the zones. Compared with manual fixing, it saves a lot of time, and the fixing is more stable. It is suitable for wooden door processing and large panel relief carving. But not all boards are suitable for fixing by vacuum adsorption. For instance, it is not suitable for hollow processing or carving workpieces with curved and uneven boards. The vacuum table is suitable for processing wood boards of about 30mm. If it is too thick, the adsorption effect will decrease.

T-slot and vacuum CNC router table

It is based on the structure of vacuum adsorption tabletop. And the aluminum is embedded in the tabletop according to customer needs. So as to meet the processing requirements for special work pieces. It can be processed for the whole panel, and it can also be clamped and processed for special work pieces.

CNC router bits

They are the basic and the smallest unit of CNC routers. CNC router bits determine the cutting and engraving type, and whether you can make a satisfactory design. So when we choose the CNC router bits, we should pay attention to the material, width, angle, diameter, and the length of the CNC router bits.

The flat milling bit is mainly used for cutting. While the ball milling bit is mainly used for the 2D engraving and relief engraving. And the pointed milling bit is mainly used for the V-shaped engraving, lettering, and line pattern sculpture.

| CNC router bits |

Cut materials |

Engraved materials |

| Flat sharp cutter |

ABS board, Two-color board, etc. |

Two-color board, PVC board, plexiglass, ABS board, etc. |

| Helical cutter |

Wood, PVC, plexiglass, etc. |

PVC, plexiglass, wood board, etc. |

| Straight cutter |

Two-color board, ABS board, etc. |

PVC, Two-color board, plexiglass, ABS, etc. |

Wanna get more detailed and complete introduction of CNC router bits for sale? Please click the link below for more information.

https://www.elephant-cnc.com/blog/complete-buyer-guide-of-cnc-router-bits/

What is a CNC router used for?

Materials

CNC router for sale can carry out relief, 2D engraving, and hollow engraving on aluminum alloy, copper, brass, aluminum, wood, stone, jade, glass, ACM, foam, plastic, acrylic, PVC, etc.

Industries

① Woodworking industry: 3D wave board processing, cabinet doors, craft wooden doors, paint-free doors, screens, craft windows, milling and carving of furniture products.

② Mold industry: relief engraving, shadow engraving, hole engraving, plane engraving, cutting, washing, etc.

③ Advertising engraving: advertising signage, PVC board, front panel, two-color board, logo making, acrylic cutting, blister molding, large character cutting, sign making, PVC cutting, crystal board, acrylic, LED/neon light groove, hole shape and text cutting, Blister light box mold making.

④ Stone carving: 3D relief of natural marble, granite, artificial stone, tombstone, landmark, ceramic tile, glass and other materials, and 2D carving such as line carving, cutting, chamfering, and drilling.

⑤ Handicrafts: carve various exquisite patterns and characters on wood, bamboo, artificial marble, organic board, two-color board, crystal, and other materials.

What are 3 advantages of CNC router?

① Wide application range - dozens of different industries

Blue Elephant CNC router machines involve various industries, such as woodworking industry, metallurgy industry, home decoration industry, wood product processing industry, musical instrument industry, tombstone manufacturing industry, advertising industry, and so on.

② Short engraving time - only a few minutes

It takes a long time to carve products by hand, a day or even more days for one person to carve a handicraft. But if it is a CNC woodworking engraving machine, it can be completed in a few minutes, which greatly reduces the required engraving time. The engraving speed of the newly launched CNC router for sale has increased several times. While the manual speed and the engraving machine speed are like one going to France on foot, and the other flying to France.

③ Greatly improved accuracy - about 30%

Compared with manual engraving method, CNC router machines can control the size better. The accuracy of some high-end CNC engraving machines can even reach the last two decimal places, which is beyond comparison with traditional engraving machines. In addition, the operation is controlled by the computer, which can ensure that there is no error in each process. The C and C router can reproduce the original design pattern, ensuring that every detail is accurately restored. It can avoid all unstable factors during manual operation, ensure the stability of mass production level, and the product qualification rate can make customers more satisfied.

How much does a CNC router cost?

As we all know, the product price is determined by many factors. Therefore, the CNC router machine price can not be sure for different configurations. But I can give you a general and average price data for reference.

For example, the 3 axis CNC router has the price range of $3500 to $10,000. And the 4 axis CNC router price is from $14,000 to $23,000. ATC CNC router machine price is similar to the 4-axis CNC router price, but can up to $30,000. The 5 axis CNC router is usually sold at the price of more than $85,000. While the nesting CNC router furniture making machine price is generally with the lowest price of $10,000 and the highest price of $50,000. The stone CNC router price is from $6500 to $35,000. And the EPS/foam CNC router cost is usually more than $35,000. Moreover, we can also make you a DIY CNC router with everything you want. But the router price will be uncertain.

How to maintain a CNC router?

CNC machines are mostly used for cutting and engraving, which will produce a lot of powder and dust. If it is not cleaned in time, it will not only affect the working life of the machine, but also reduce the processing accuracy. Therefore, Blue Elephant will teach you how to realize the daily maintenance of CNC machines in ten steps to avoid processing troubles and improve working efficiency.

10 steps to maintain a CNC router

1.When maintaining and inspecting electrical appliances of CNC woodworking engraving machine, be sure to cut off the power supply. Wait until the monitor has no display and the main circuit power indicator light goes out before proceeding.

2.Weekly lubricate the transmission system like ricks, ball screws, and X, Y, Z axis to extend machine life.

3.When using a water-cooled spindle, ensuring the cleanness of the cooling water and the normal operation of the water pump. If the working environment temperature is too low in winter, the water in the water tank can be replaced with antifreeze.

4.The power consumption of CNC wood cutting machine is large, so a voltage regulator should be added to ensure the ground connection.

5. Don’t place the machine in a humid place. Choose a well-ventilated place, and do not expose it to the sun.

6.Do not place debris, corrosive, or magnetic substances that can interfere with the work of the machine on the table. Prevent some accessories from interfering with the normal operation of the machine due to magnetization.

7.Regularly clean the screw and frequently lubricate the rotating parts and tracks. On the one hand, it will ensure that the machine can efficiently complete the rotation and movement. On the other hand, it will reduce wear and tear.

8.Check whether the lines of control box and machine are loose or mixed. Because the long-term use may cause the leakage.

9.The continuous running time of the CNC wood router should be less than 10 hours per day.

10. CNC router spindle is prone to rust without regularly maintenance, which will make cutting and engraving mistakes. Therefore, we should use tools and lubricating cleaners to derust the spindle for better results.

Get more maintenance methods? We have very professional after-sales service team teach you online with videos.

Word at Last

We should get it by now that CNC router machine can be classified as various types according to different criteria, such as metal processing CNC router and non-metal processing CNC router. And the control system, software, drive mode, and transmission mode should also be chosen seriously. In addition, the maintenance and support service are important factors of choosing the best CNC router for sale. We wrote this article only for customers to use as a reference for purchase. If there are any other aspects not mentioned but you want to know, you can freely email us. We will answer you as soon as possible~

More feedback from customers all over the world can be found in our

Facebook.Machine working videos, machine display video, machine operation videos, customer praise videos, etc., will be showed in our

YouTube.