2050 3 Axis CNC Router

2030 3 Axis CNC Router

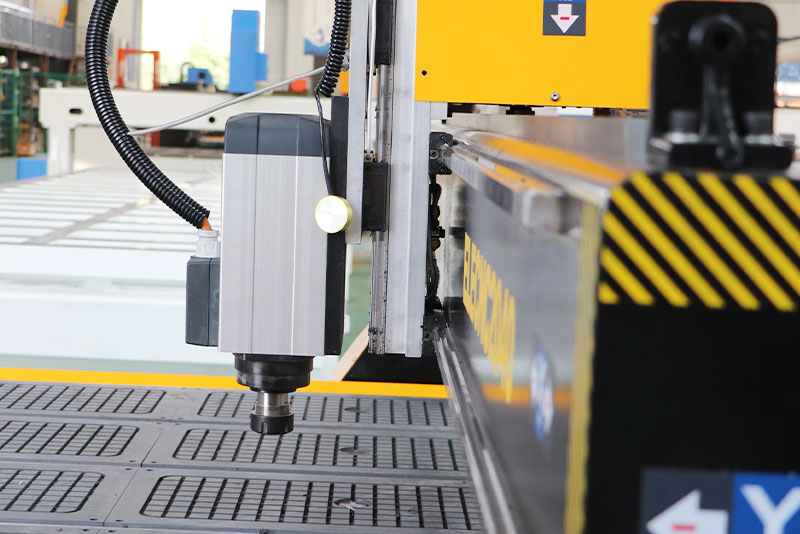

This 3 axis CNC router Wood Carving Machine is suitable for high-speed 2D/3D wood engraving, MDF cutting, furniture carving, door/cabinet making, etc. A large table and strong machine body makes it good at 2D/3D wood letters/crafts and carpentry of big and heavy. If you want to do some baisc woodworking, this type of CNC wood router is your better choice.

1. This CNC Wood Carving Machine has the features of high cost performance, simple operation, and high practicality. Meanwhile, control system of NK105, Mach3 also are available.

2. New Strong bed structure for large and heavy workpieces, it makes a more stable performance, which is important for accurate works. Large table is good for high speed Wood & Furniture Carving.

3. Powerful HSD air cooling spindle, it can meet long time 2D/3D cutting & carving on hardwood, 4x8 MDF sheet, 4x8 plywood, it is also good at working on soft metals, such as Aluminum, Copper engraving & cutting.

4. T-slot+Vacuum table, Vacuum function for workpiece of big plate fixing firmly on the table, efficient & easy to use. T-slot clamps also available for small workpieces.

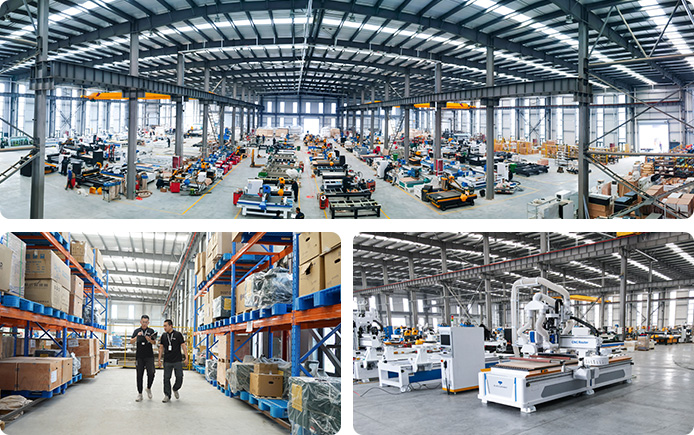

5. All CNC Wood Carving Machine we accept customized requirements, such as the working table size, cnc kits/parts such as control system, moters, etc., or other functions, we'd like to assemble machine as you request.

Note: Upgradeable machine recommended: 4 Axis 3D CNC Wood Carving Machine + Rotary Device + Automatic Spindle or 3 Aixs CNC with Rotary Device for complex woodworking, it is an upgrade version of 3 Axis.

| Model | ELECNC2040 |

| X,Y axis travel | 2000x4000mm, option: 1300*250mm, 1500*3000mm; 2100*3000mm; etc. |

| Z axis travel | 200mm, option: 300mm, 400mm, 500mm, 600mm, etc. |

| Spindle type | 6kw Italian HSD air cooling spindle, 18000rpm |

| Inverter type | 7.5kw |

| Drilling bank | Option: Taiwan or Italy 5+4 vertical drills |

| Tool holder with collet | ER32 collet: φ4, φ6, 1/8, 1/2 |

| Control system | Ncstudio DSP A11, option: Taiwan SYNTEC /LNC controller |

| Driving system | Stepper motor and Leadshine driver, option: Japan YASAKWA Ac servo |

| Reducer | Without |

| Machine structure | Heavy duty body with quenching treatment |

| Work table | Aluminum T-slot & vacuum work table |

| Positioning cylinder | Option: 7 pieces (X3,Y4) |

| Linear guide | Taiwan Linear guide |

| Transmission | X, Y axis: Taiwan /Germany Helical Rack and Pinion Z axis: Taiwan TBI high precision ball screw |

| Lubrication system | 1.5L automatic lubrication system |

| Tool calibration | Tool sensor calibration |

| Cables | Germany Igus cables with CE, cUL certificate |

| Compatible software | Artcam, Alphcam, Type 3,Ucancam, Aspire, etc. |

| Command language | G Code & M Code |

| Traveling speed | 80m/min |

| Working speed | 0-25m/min |

| Re-positioning accuracy | ±0.03mm |

| System resolution | ±0.0025mm |

| Working accuracy | ±0.03mm |

| Working air pressure | No need |

| Working voltage | 220V 1PH/3PH 50HZ/60HZ 380V 3PH 50HZ/ 60HZ |

| Vacuum pump |

|

| Dust collect system |

|

| Air compressor | Piston air compressor, screw air compressor |

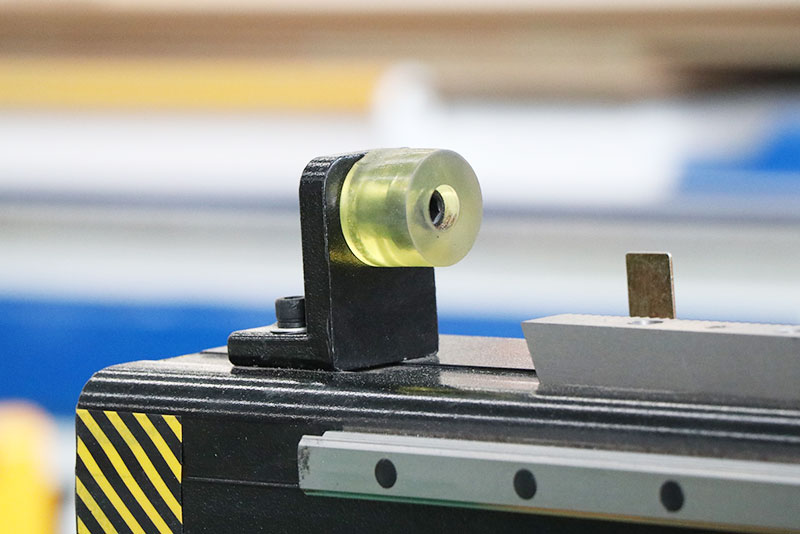

| Protection device | Light curtain |

| Spindle type | ATC spindle |

| Rotary device | Industrial-grade support of rotary device,diameter 200mm, 320mm. |

Click for details

Spindle

Z axis

Electric part

Hard limit

Click for solution

Click for quotation