Aluminum is the main raw material of the metal processing industry. Through cutting, engraving, and hollowing, people use it to produce aluminum sheets, hollow doors and windows, handrails, screens, and handicrafts.

The application of these products includes exterior walls and interior decorations of buildings. We may also see them in airports, exhibition halls, subways stations, office buildings, shopping malls, and office buildings.

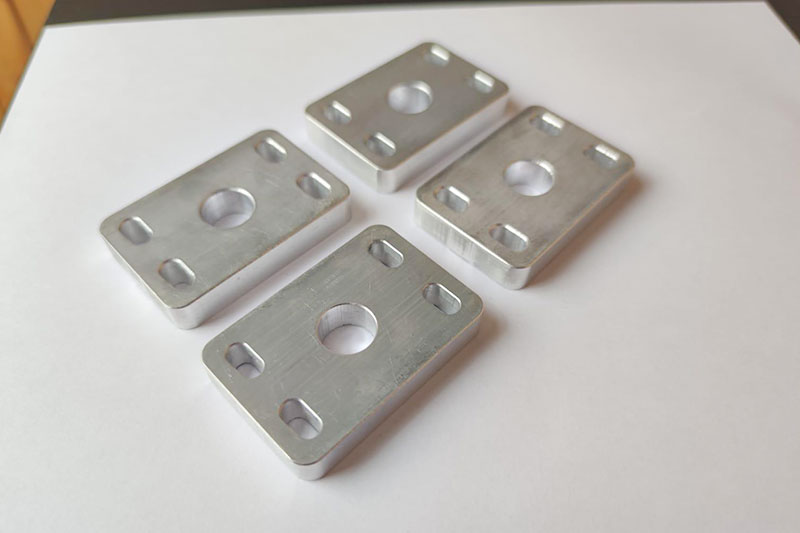

Processing aluminum is one of the applications of CNC router machines. With different CNC router bits, the CNC router can complete multiple aluminum processing. For example, cutting, engraving, drilling, milling, etc. The CNC router aluminum projects have wide usage in aluminum windows and doors, aluminum parts, molds, daily supplies, etc.

CNC router aluminum processing is achieved by different bits milling the aluminum sheet surface repeatedly along the given path. The 3 axis CNC router can realize plane cutting, engraving, and milling work of aluminum sheets. While the 4 axis CNC router or 5 axis CNC machining center can complete 3D engraving and milling work of aluminum workpieces.

It requires appropriate bits for CNC router aluminum processing. Aluminum belongs to soft metals, which means the bits will not be subjected to hard impact when cutting. We can use a single-edged aluminum milling cutter to cut aluminum sheet, which doesn’t stick chips and has fast speed and high efficiency. Moreover, 2 flutes or 3 flutes CNC bits can also be used to cut aluminum sheets.