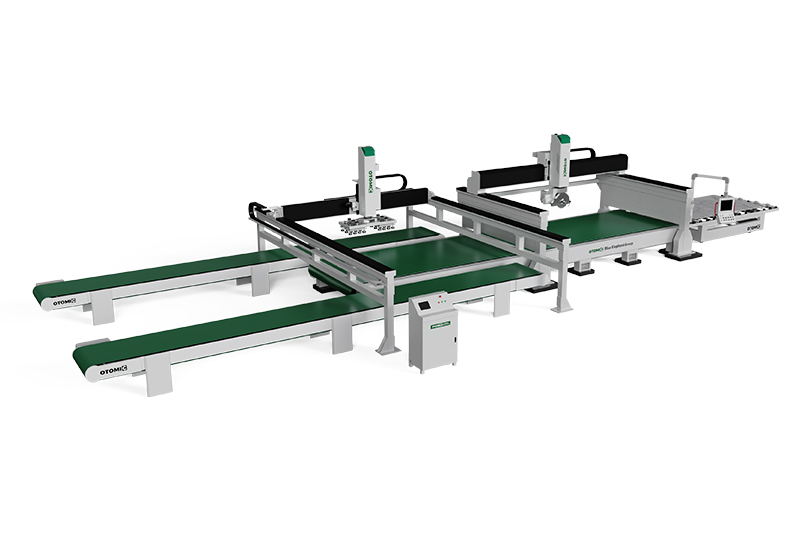

5 Axis CNC Granite Stone Bridge Saw

5-Axis Marble Slab Bridge Cutting Saw

This quartz stone cutting production line is a newly high-end stone processing center. The 5 axis bridge saw quartz stone cutting line includes three parts: a loading machine, a 5 axis bridge saw machine and an an unloading machine.

This quartz stone production line can solve various special-shaped processing of stone materials. It is compatible with functions of stone cutting, profiling, special-shaped cutting, etc. It gains popularity in stone processing for waterscapes, gardens, and high-end villas.

1. Automatic stone loading

Place the large stone slabs on the fully automatic loading machine. Thus it will transport the stone slabs to the 5-axis bridge cutting machine. It will save loading time and labor, and improves work efficiency.

2. 5 axis bridge saw machine

The 5 axis bridge saw machine can take pictures and position through the visual function. It can also cut according to the pre-arranged engineering documents, making it more intelligent and easier to operate.

3. High automation

The production line control system automatically sets tools, moves stone slabs, and completes stone cutting.

4. Automatic stone unloading

According to the process, we can assign the automatic unloading machine to designated wire racks or palletizing racks. It greatly saves unloading time and reduces manual errors.

| QX3400-5X-SP Quartz Stone Cutting Production Line | |||

| Bridge Saw | Working travel | X, Y, and Z | 3400*2000*250mm |

| C axis | ±365° | ||

| A axis | 0-90° | ||

| Maximum thickness | 80mm | ||

| Moving speed | 25m/min | ||

| Spindle | 22kw air cooling spindle, 4000rpm | ||

| Control system | CutCam | ||

| Motor | CutCam servo | ||

| Reducer | Japan SHIMPO | ||

| Worktable (optional) | Max. weight for feeding | 1500kg | |

| Max. speed for feeding | 10m/min | ||

| Saw | Dimension | 450mm | |

| Size | 6000×3500×3600mm | ||

| Loader | Working travel | X, Y, and Z | 3500*4000*1000mm |

| A axis | 0-90° | ||

| Control system | CutCam | ||

| Motor | CutCam servo | ||

| Reducer | Japan SHIMPO | ||

| Moving speed | 25m/min | ||

| Max suction size | 3200×1200mm | ||

| Min suction size | 300×150mm | ||

| Power | 8kw | ||

| Weight | 3000kg | ||

| Machine size | 5000×5800×3800mm | ||

Click for details

Click for solution

Click for quotation