Edge banding machines are widely used in furniture manufacturing, cabinet making, door and window manufacturing and other fields. They play a very important role in panel furniture manufacturing, and edge banding is an important process in furniture manufacturing. Therefore, using edge banding machines to make money is a very feasible way. The following will introduce the basic knowledge of edge banding machines and 8 ways to make money using edge banding machines.

Ⅰ. What Is An Edge Banding Machine?

As the name implies,

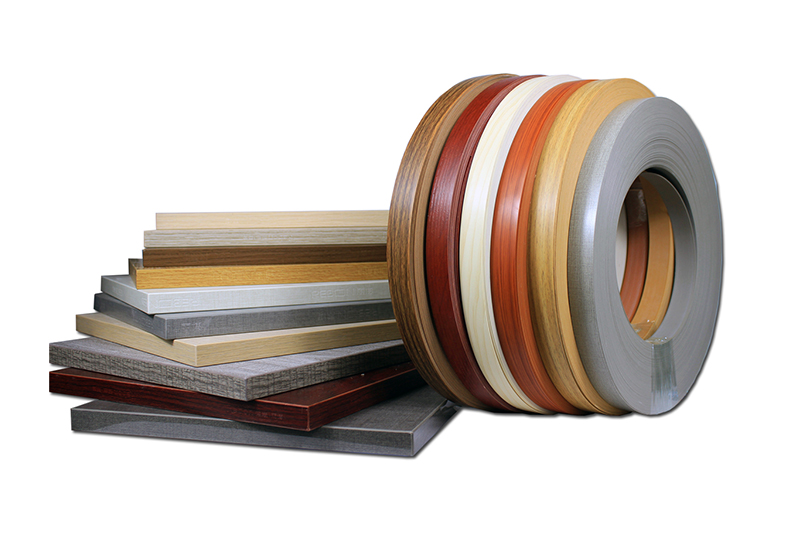

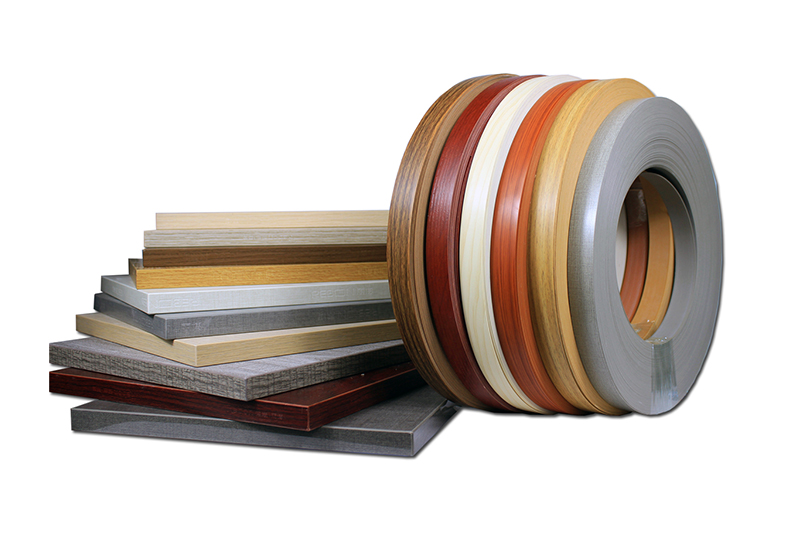

edge banding machine is a machine used for edge banding. It is a special equipment used in furniture manufacturing and woodworking processing, which replaces manual edge banding procedures. Its main function is to stick edge banding materials (such as PVC, ABS, veneer, etc.) to the edges of wood, particleboard, medium-density fiberboard and other boards. Edge banding machines are usually used for edge banding of furniture boards to improve the aesthetics, durability and moisture resistance of the products.

The basic working principle of edge banding machines is to tightly combine edge banding materials with the edges of boards through heating and pressure. The main processing procedures include conveying, gluing and edging, cutting, front and back head alignment, upper and lower trimming, upper and lower fine trimming, upper and lower scraping, polishing, etc.

Ⅱ. Types of Edge Banding Machines

Edge banding machines can be divided into the following types according to the degree of automation, operation mode and usage scenarios:

1. Manual edge banding machineManual edge banding machine is the most basic edge banding equipment, usually used for small-scale or customized furniture production. This type of edge banding machine is simple to operate and mainly relies on manual operation. It is suitable for small batch processing and edge banding of irregular shaped boards. Manual edge banding machines usually require workers to manually adjust the alignment of edge banding materials and boards, and then manually push the boards through the edge banding machine.

Due to its flexible operation, manual edge banding machines are very suitable for small workshops or operations that require processing complex shapes and special materials. However, due to the need for manual intervention, its production efficiency is low, and the quality of edge banding depends on the experience and skills of the operator.

2. Semi-automatic edge banding machine

2. Semi-automatic edge banding machineSemi-automatic edge banding machines are more advanced than manual edge banding machines and are suitable for small and medium-sized enterprises. It has a high degree of automation and can automatically complete some operations, such as gluing, edge pressing, etc., but it still requires manual intervention to complete feeding and some adjustments.

It is suitable for businesses that require a certain scale of production but still need the flexibility to handle different panels. Compared with manual edge banding machines, semi-automatic edge banding machines can significantly reduce workers' work intensity and improve the consistency of edge banding.

3. Fully automatic edge banding machine

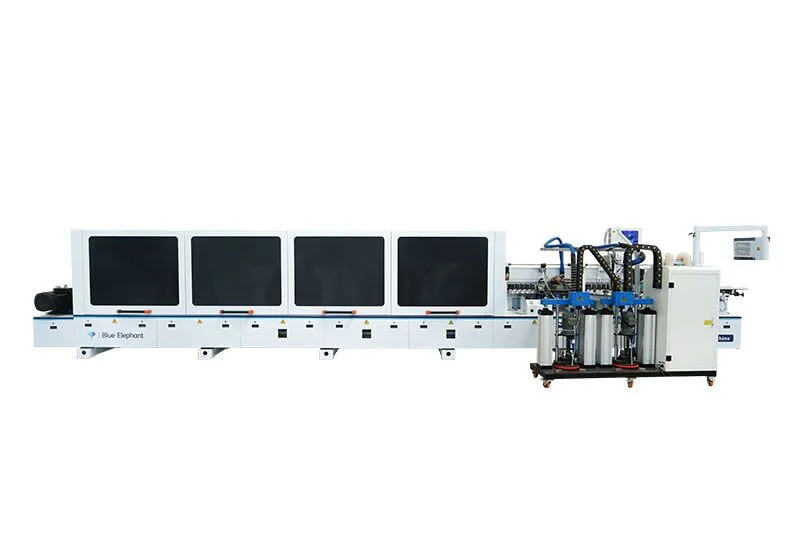

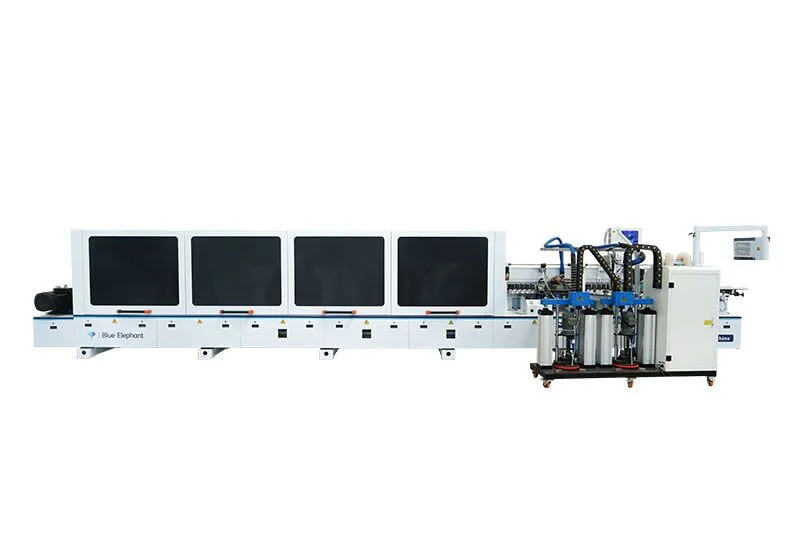

3. Fully automatic edge banding machineFully automatic edge banding machine is the most advanced edge banding equipment on the market and is widely used in large-scale industrial production lines. Fully automatic edge banding machine can automatically complete the entire edge banding process, including feeding, edge banding, cutting, trimming, scraping and polishing.

Its efficient and precise edge banding capabilities make it an ideal choice for mass production. Fully automatic edge banding machines are usually equipped with advanced control systems that can be programmed and automatically adjusted to ensure the accuracy and consistency of edge banding. This type of equipment is suitable for companies with large production scales, a wide variety of products and high efficiency.

Ⅲ. 8 Ways to Make Money with An Edge Banding Machine for Plywood, MDF

There are many ways to make money with edge banding machines, especially in the furniture manufacturing and decoration industries. Edge banding machines are widely used and can help you make considerable profits in different business models.

1. Custom Furniture Edge Banding Service

The demand for custom furniture market is growing, and consumers have a strong demand for personalized, high-quality furniture. By providing edge banding services for custom furniture, you can help furniture manufacturers or individual customers improve the appearance and durability of their products.

Edge banding not only makes furniture more beautiful, but also protects the edges of furniture and extends its service life. In the high-end market, especially among customers who pay attention to details and quality, providing fine edge banding services can charge higher fees and obtain better profits.

2. Small Batch Order Processing

Small and medium-sized furniture manufacturers or woodworking shops usually find it difficult to undertake large-volume edge banding orders, but they still have edge banding needs. By providing small-batch edge banding processing services, you can fill this market gap.

You can establish long-term cooperative relationships with these companies and become their reliable edge banding service provider. In this model, flexible production capacity and efficient service are key. You need to be able to respond quickly to customer needs and ensure processing quality.

3. Home Decoration Edge Banding Service

The home decoration market has a huge demand for custom cabinets, wardrobes, and other wood products. By working with home decoration companies or individual customers to provide edge banding services for these furniture, you can expand your business scope.

In the home decoration industry, owners are often willing to pay more for high-quality custom furniture. Therefore, providing professional edge banding services can not only improve the overall quality of the furniture, but also help you stand out in this competitive market.

4. Start A Carpentry Training Course

If you have extensive experience using edgebanders, consider starting a carpentry training course to teach beginners or experienced carpenters how to use edgebanders correctly. By providing hands-on training on edgebanding techniques, equipment maintenance, and troubleshooting, you can attract people who are looking to improve their skills or are planning to work in the carpentry industry. This training can be done offline or through online courses.

With the popularity of online learning, making and selling tutorials and videos on how to use edgebanders is a great way to make money. You can create detailed tutorials that cover the operation, maintenance, troubleshooting, and other aspects of edgebanders and sell these courses or video content. Through platforms such as YouTube, Udemy, etc., you can promote this content to users around the world and earn continuous passive income.

5. Edge Banding Material Sales

Edge banding processing is inseparable from materials such as edge banding strips and glue. Combined with edge banding services, you can sell these edge banding materials and provide one-stop services. By purchasing and selling in bulk, you can reduce costs and increase revenue. In addition, providing high-quality edge banding materials can also improve customer satisfaction with your services and encourage them to continue to cooperate with you.

6. Mobile Edge Banding Service

Mobile edge banding service is a flexible business model that is particularly suitable for small and medium-sized family workshops and DIY enthusiasts. You can provide door-to-door edge banding services to help customers complete edge banding processing at their workplace.

In this way, you can facilitate customers, reduce their transportation costs, and expand your business scope. This type of service is particularly suitable for customer groups who do not have edge banding machines or are not familiar with edge banding operations.

7. Refurbishment and Sales of Second-hand Edge Banding Machines

There is also a certain demand in the second-hand edge banding market. You can purchase second-hand edge banding machines, refurbish and repair them, and then sell them at a higher price. This business model can help customers who have a limited budget but still need edge banding machines.

By flexibly applying these methods and adjusting them according to market demand and personal resources, you can find a stable way to make profits in the furniture manufacturing and decoration industry. The key is to provide high-quality services, establish good customer relationships, and continuously optimize the business model.

8. Professional After-sales Maintenance Service

After mastering the various technologies of edge banding machines, you can consider professional after-sales maintenance services for edge banding machines. At present, there is a large demand for after-sales maintenance of edge banding machines. If you have been engaged in the edge banding machine industry for many years and have relevant technical backgrounds, then you can focus on providing high-quality after-sales maintenance services.

Ⅳ.How Do I Start An Edge Banding Business?

1. Understand the Industry Background and Market Demand

With the improvement of furniture quality requirements in modern home decoration, edge banding technology is also constantly upgrading, and the market demand for efficient, accurate and environmentally friendly edge banding equipment is increasing. Therefore, it is very feasible to make money with edge banding machines.

2. Master Relevant Technical Knowledge

To start an edge banding machine business, mastering edge banding technology is the basis. The working principle, types, technical parameters, operating skills and maintenance knowledge of edge banding machines are all things you need to have a deep understanding of. Mastering this knowledge can not only help you better understand market demand, but also communicate more effectively with customers during actual operation and sales.

3. Own A Good Edge Banding Machine

Among many projects that can make money using edge banding machines, using edge banding machines for processing and production is the most common way to make money, provided that you own one or more good edge banding machines. After practicing the edge banding machine and mastering various edge banding machine technologies, you can start other money-making projects.

Among many edge banding machine manufacturers at home and abroad,

Blue Elephant's edge banding machine can be regarded as the most cost-effective machine. The following are some edge banding machine recommendations.

Manual edge banding machine

| Voltage |

220V, 50hz |

| Heating power |

1.2kw |

| Air pressure |

0.3-0.6mpa |

| Motor Power |

0.18kw |

| Total power |

1.4kw |

| Edge thickness |

0.3-3mm |

| Edge width |

8-50mm |

| Edge banding speed |

0-26cm/s |

| Dimensions |

125*74*98cm |

| Weight |

88kg |

Semi-automatic edge banding machine

| Low voltage electrical appliance |

Korea LS Power Generation |

| Temperature control table |

Korea Autonics |

| Travel switch |

South Korea Kaikun |

| Cylinder |

WSN |

| Feed rate |

12-22m/min |

| Sheet thickness |

10-60mm |

| Edge band thickness |

0.4-3mm |

| Working pressure |

0.6Mpa |

Fully automatic edge banding machine

| Model |

E-70 |

| Overall size (LxWxH) |

5840x970x1800mm |

| Working pressure |

0.6Mpa |

| Total power |

12kW |

| Feed speed |

15-23m/min |

| Electric lifting |

0.37kW |

| Panel thickness |

10-60mm |

| Panel length |

≥120mm |

| Panel width |

≥80mm |

| Edge band thickness |

0.4-3mm |

As a cost-effective fully automatic edge banding machine, it can complete gluing, banding, edge cutting, rough trimming, fine trimming, tracking, scraping and polishing functions automatically. You can use it for banding various wooden boards, such as density boards, fiber boards, particle boards, solid wood panels, etc.

learn more

4. Choose the Right Entry Point

Depending on your resources and interests, you can enter the edge banding machine industry from different entry points:

Manufacturing: If you have certain funds and technical capabilities, you can consider directly participating in the research and development and manufacturing of edge banding machines. This requires the establishment of a technical team, the purchase of relevant equipment, and the establishment of a brand image in the market.

Sales and agency: If you want to reduce risks, you can consider starting with the sales or agency of edge banding machines. Cooperate with well-known brands, understand product features and market demand, and gradually accumulate industry experience and customer resources.

5. Establish A Supply Chain and Sales Network

Successfully entering the edge banding machine industry requires a stable supply chain and a wide sales network. First, you need to establish a cooperative relationship with upstream suppliers to ensure the quality and stability of equipment parts. Secondly, develop the downstream market and promote your products through various channels (such as exhibitions, online sales platforms, dealer networks, etc.). Establish a customer relationship management system, follow up customer feedback in a timely manner, and continuously optimize products and services.

6. Pay Attention to Industry Trends and Technological Innovation

Regularly attend industry exhibitions and seminars to learn about the latest market trends and technological developments. At the same time, invest in research and development funds to continuously improve product performance to meet the market's demand for efficient, environmentally friendly, and intelligent equipment.

Entering the edge banding industry requires a comprehensive consideration of market demand, technical capabilities, financial strength, and business strategies. At the same time, paying attention to industry trends and technological innovations, and continuously learning and improving your own abilities are the keys to standing out in the fierce competition.

Ⅴ.Conclusion

You can make money with edge banding machines by providing professional edge banding services, providing exquisite edge banding products for cabinet production, interior decoration, etc., providing edge banding machine online training courses or edge banding machine maintenance services.

If you have the idea of making money with edge banding machines, do it boldly. Pay attention to the way to invest and make money. I believe you can use edge banding machines to gain your wealth in life. If you have any questions about edge banding machines, you can consult Blue Elephant.