Panel saw is a machine that cuts various materials through system control. It is a cutting equipment used in woodworking and furniture manufacturing industries. It usually consists of a workbench, saw blade, guide rail, motor, etc. The working principle of the panel saw is to accurately cut the board in a straight line through a high-speed rotating saw blade to meet the requirements of various sizes.

Panel saws are widely used in wood processing plants, furniture manufacturing plants and other places, and can handle a variety of materials such as plywood, particleboard, medium-density fiberboard and solid wood boards. Due to its easy operation, stable performance, safe production and high cutting accuracy, it has become a key equipment for board processing.

Ⅱ.How Many Types of Panel Saw Machines?

Based on the structure and function, panel saws are mainly divided into manual panel saws, sliding table panel saws, vertical panel saws, computer panel saws, etc. Among them, sliding table saw and computer panel saw are the most commonly used panel saws.

Manual panel saw: This type of panel saw relies on manual pushing of the board, and the material is fed into the saw blade for cutting through manual operation. It is suitable for small-scale wood processing or home work, with low cost, but relatively low efficiency and precision.

Sliding table panel saw:

Sliding table panel saw: The sliding table panel saw, also known as the precision push-table saw, is a high-precision panel saw with a sliding table device that allows the board to move smoothly during the sawing process. This type of panel saw is usually used in occasions that require high-precision cutting, such as high-end furniture manufacturing and precision woodworking.

Computer panel saw: Computer panel saw is equipped with a computer control system that can automatically control the cutting process through programming. This type of panel saw can achieve highly automated operation, suitable for large-scale production, and has extremely high cutting accuracy and efficiency.

Vertical panel saw: The design of the vertical panel saw makes it take up less space and is suitable for use in workplaces with limited space. This type of panel saw is usually used to cut smaller-sized panels and is easy to operate.

Different types of panel saws have their own advantages and application scenarios. Users can choose the appropriate panel saw according to their needs.

Ⅲ.What’s The Price of Panel Saw Machine for Wood Panel Cutting?

Panel Saw Price Overview

| Panel Saw Type |

Panel Saw Prices |

| Manual panel saw |

$400 to $2,000 |

| Semi-automatic panel saw |

$1,000 to $10,000 |

| Fully automatic panel saw |

$10,000 to $40,000 |

| Sliding table saw |

$2,000 to $5,000 |

The price of panel saws varies greatly depending on the type, brand, specification and function, ranging from a few hundred dollars to tens of thousands of dollars. Below are the prices of several common panel saws.

Manual Panel Saw: This kind of panel saw has a simple structure, and the operation mainly relies on manual pushing of materials. It is suitable for small and medium-sized processing plants as well as individual users.

Manual panel saws are relatively inexpensive, generally between $400 and $2,000, depending on the brand, features, and configuration. Manual panel saw has high technical requirements and relatively low production efficiency, which is suitable for occasions with low efficiency requirements.

Semi-automatic Panel Saw: Compared with manual panel saw, semi-automatic panel saw adds some automation functions, which can improve production efficiency. It usually costs between $1,000 and $10,000. Semi-automatic panel saw operation is relatively simple, suitable for medium-sized processing enterprises.

Fully Automatic Panel Saw: Fully automatic panel saw has a high level of automation, can greatly improve production efficiency, and reduce manual operation. Equipped with automatic feeding, positioning and cutting systems, the equipment is suitable for large-scale industrial production. Automatic panel saws are mainly computer panel saws.

Fully automatic panel saws typically cost between $10,000 and $40,000 or more. Because of its superior performance and high efficiency, it is widely used in furniture manufacturing, custom home furnishing and other fields.

Sliding Table Saw: Sliding table saw is a very common type of panel saw, because of its stable structure, easy operation, high cutting accuracy, favored by small and medium-sized factories. Table saws can cost anywhere from $2,000 to $5,000 depending on the length of the table, blade diameter, and motor power. High-end table saw with higher precision and automation, suitable for mass production.

Ⅳ.7 Factors that Influence Panel Saw Machine Prices

1. Brand and Reputation

Brand is one of the important factors that affect the price of panel saws. Well-known brands usually have higher market recognition and customer trust, and therefore higher prices. These brands often excel in product quality, after-sales service and technical support, and consumers are willing to pay a premium for them. In addition, the reputation of the brand also reflects the company's technological accumulation and innovation capabilities in the industry.

2. Technical Parameters and Performance

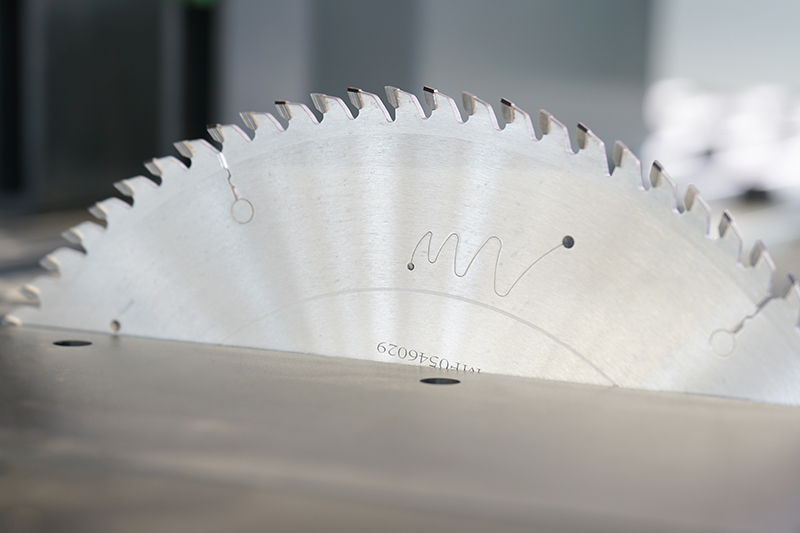

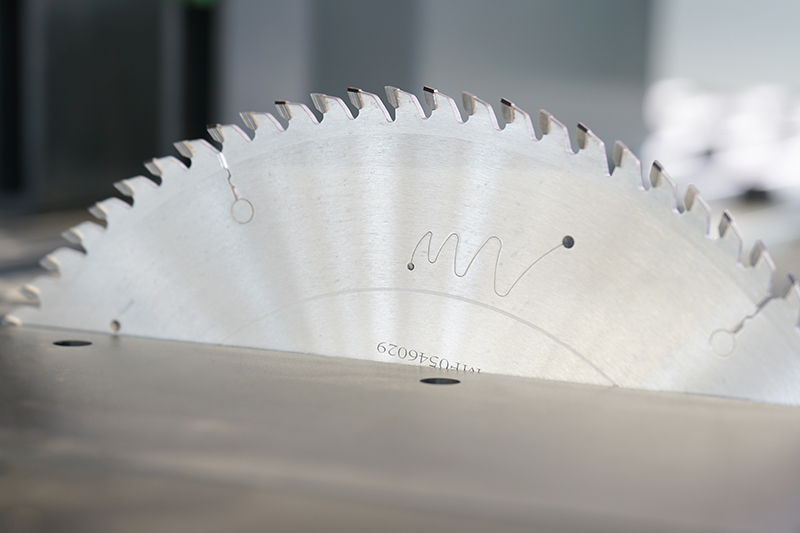

The technical parameters and performance of the panel saw directly affect its price. The diameter of the saw blade, cutting accuracy, cutting speed, power, and maximum cutting thickness are all key parameters. The higher these parameters are, the higher the manufacturing cost and technical requirements of the panel saw will be, and the price will naturally be higher.

For example, high-precision panel saws can provide smoother cutting effects and are suitable for high-end furniture manufacturing, and the price of these devices is usually more expensive.

3. Materials and Manufacturing Processes

The manufacturing materials and workmanship of a panel saw have a direct impact on the price. Panel saws made of high-quality steel and high-strength alloys are more durable, can maintain cutting accuracy for a long time, and are not prone to wear and tear.

In addition, the complexity and precision of the manufacturing process also affects costs. Some high-end panel saws may use precision casting or CNC machining processes, which significantly increase production costs and thus push up market prices.

4. Degree of Automation

Modern panel saws are becoming more and more automated. Automated functions include automatic feeding, automatic adjustment of cutting angles, automatic calculation and optimization of cutting paths, etc. Highly automated panel saws not only improve production efficiency, but also reduce manual intervention, thereby reducing the possibility of human error.

However, the realization of automation functions requires more complex control systems and sensor technology, which undoubtedly increases the R&D and production costs of the equipment, so the selling price of these equipment is also higher.

5. After-sales Service and Warranty Policy

After-sales service and warranty policy are also a factor affecting the price of panel saws. High-quality after-sales service includes installation and commissioning, operation training, regular maintenance and troubleshooting, etc. These services can effectively extend the service life of the equipment and reduce downtime.

Some brands may also provide longer warranty services, or even lifetime warranty, which increases consumer trust and also increases the price of the product.

6. Transportation and Installation Costs

Panel saws are large equipment, and the transportation and installation costs cannot be ignored. The larger and heavier the equipment, the more difficult and expensive it is to transport and install. If the equipment requires long-distance transportation or special installation conditions, these additional costs are often passed on to the terminal selling price.

7. Imports and Tariffs

For imported panel saws, tariffs and import taxes are additional factors that affect the price. Some high-end panel saws may need to be imported from abroad, which not only increases logistics costs, but also involves tariffs, value-added tax and other fees, which will be reflected in the final sales price.

Ⅴ. 7 Smart Tips for Panel Saw Machine Buying

1. Understand Your Needs

First, consider the size of the material you want to process. Choose a machine with the appropriate number of air-floating tables according to the maximum cutting size and cutting thickness.

Secondly, choose the appropriate type of panel saw according to your processing scale. If it is used for small-scale wood processing or home use, it is recommended to buy a manual panel saw; if it is used for medium-sized enterprise processing, it is recommended to choose a semi-automatic panel saw; if it is for large-scale industrial production, you can choose a fully automatic panel saw, that is, a computer saw for board processing.

2. Plan Your Budget

Develop a realistic budget that meets your processing needs and financial situation. Buy a machine based on your real needs, and don't blindly pursue high-end machines and ignore your actual budget. Remember that simple machines can do the same good work as advanced machines.

3. Choose A Reputable Brand

Choosing a well-known brand can guarantee product quality. Big brands will work harder on product configuration and invest more money in technology, so the quality of their products will be more guaranteed. If you research Blue Elephant, you will find that Blue Elephant's machines are of better quality than other companies, and the price is relatively higher. This is because Blue Elephant has invested more in the research and development of the machine's technology, but it will definitely ensure that you get the best value for money.

4. Explore the Used Machine Market

If you have a limited budget, then a used machine will be a very good choice. There are many relatively new used machines on the market, and the wear and tear of the machines is almost negligible. Such machines can be purchased. When purchasing a used machine, be sure to thoroughly inspect and test the used machine to avoid problems in the future. This is the disadvantage of used machines.

5. Investigate Financing Options

Check the financing or leasing plans offered by manufacturers or financial institutions, and you can appropriately use financing to purchase the machine. Some manufacturers offer flexible payment methods that can be paid in installments, which is particularly useful for businesses with limited budgets. These plans can help you spread the cost of purchasing the machine and facilitate capital turnover in the later stage.

6. On-site Visit and Trial Experience

If you have the opportunity, visit the manufacturer's factory for a field visit before purchasing, perform actual operation of the saw, and experience the operation and processing effect of the saw. Choose the ideal machine in your mind.

Blue Elephant receives more than ten visiting customers from all over the world every day. After visiting the Blue Elephant factory, customers have given unanimous praise to Blue Elephant's machines.

7. After-sales Service

After-sales service is particularly important when purchasing a panel saw, especially when the equipment has problems and needs repair. Understand the warranty period provided. Usually high-quality products will provide a warranty period of 1-5 years or even longer.

General after-sales services include the following: First, installation and commissioning. Regular manufacturers will provide professional technicians to install and commission on-site to ensure the normal operation of the machine. The second is the repair and maintenance of the equipment. When the machine fails, it can also provide commonly used consumables and accessories.

Some manufacturers also provide telephone, online, or on-site technical guidance to help customers solve problems in operation. When the machine is just purchased, training services can also be provided to ensure that customers can operate the machine safely and correctly.

Blue Elephant's after-sales service is very complete, and we have a professional technical team. After the customer receives the machine, we will provide online and offline technical guidance, and go to the customer's factory for on-site teaching; secondly, if the machine has a malfunction, we will solve it for the customer as soon as possible; all machines have a warranty. The above after-sales service allows customers to buy our machines with confidence.

Ⅵ.Conclusion

Panel saws are important machines in the woodworking furniture manufacturing industry and play an important role in furniture manufacturing. The price of a panel saw is an important factor to consider when buying a panel saw. I believe that after reading this article, you will have a better understanding of the price of a panel saw and make a choice that suits you. Remember, you can use the above tips when buying a panel saw. I hope you can buy a panel saw you like.

If you have any questions, please feel free to contact us:https://www.elephant-cnc.com/

Email: manager@elephant-cnc.com

Whatsapp/mobile: +86-15064026772