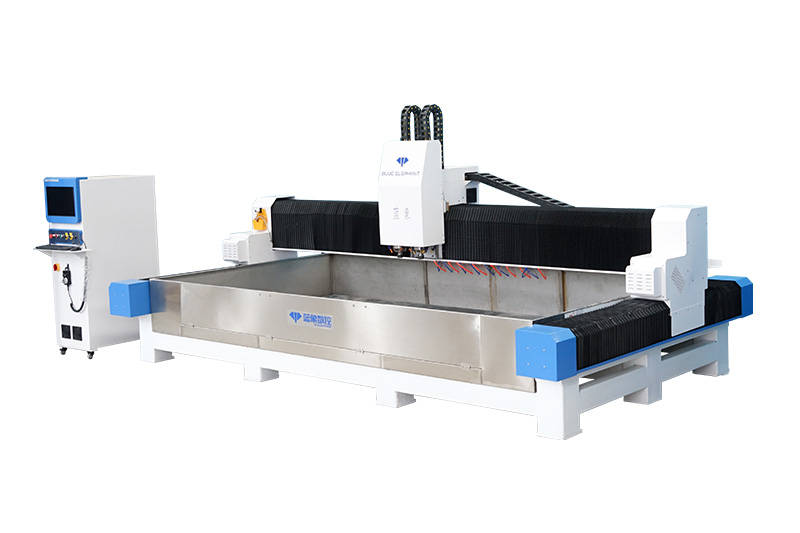

Two-process Stone CNC Machining Center

3015 Quartz Stone CNC Machine Center

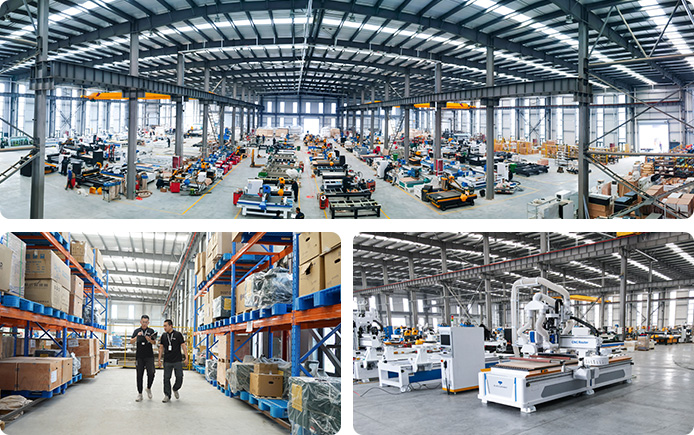

This two-process stone processing center has many advantages. Such as small footprint, low investment cost, and high utilization of personnel and equipment. It can help users realize the processing functions of edging and engraving. It is suitable for users who have a small amount of engraving needs.

1.It can help customers realize edging and engraving functions of the countertops. One machine has multiple functions and has a small footprint.

2.One-key operation can switch the edging function and engraving function of countertops , which is easy to operate.

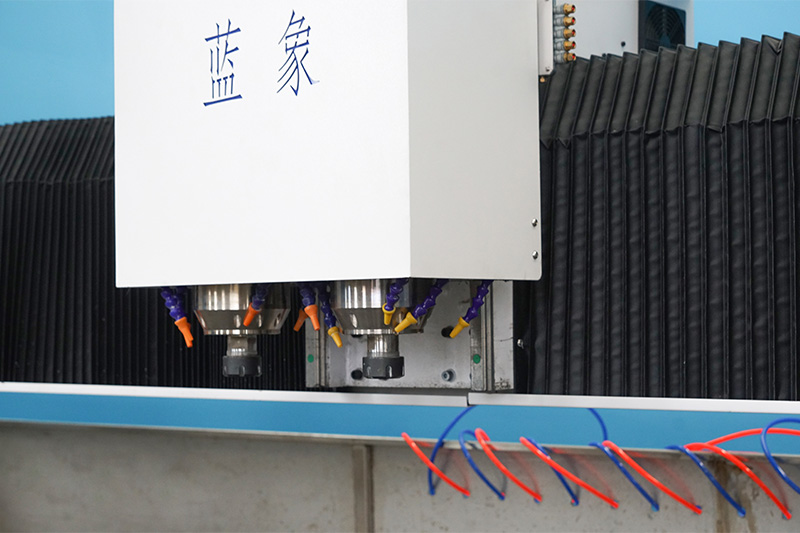

3.This machine can realize fast tool change in 3 seconds, with more powerful functions and higher processing efficiency.

4.According to processing requirements, the two spindles can automatically switch. This reduces tool change time and wastes, and improves processing efficiency.

| Model | ELECNC1530 |

| X,Y axis travel | 1500*3000mm, option: 1300*2500mm; 2100*3000mm; 2100*4000mm, etc |

| Z axis travel | 200mm, option: 300mm, 400mm,etc |

| Spindle type | 5.5kw water cooling spindle*2, |

| Inverter type | 5.5kw inverter |

| Control system | Weihong 95A-3L controller |

| Driving system | 1.5kw servo motor and driver |

| Reducer | Japan Shimpo reducer |

| Machine structure | Heavy duty body with quenching treatment |

| Work table | Stone special working table |

| Linear guide | Taiwan linear guide |

| Transmission | X,Y axis: Taiwan Helical Rack and Pinion Z axis: Taiwan TBI high precision ball screw |

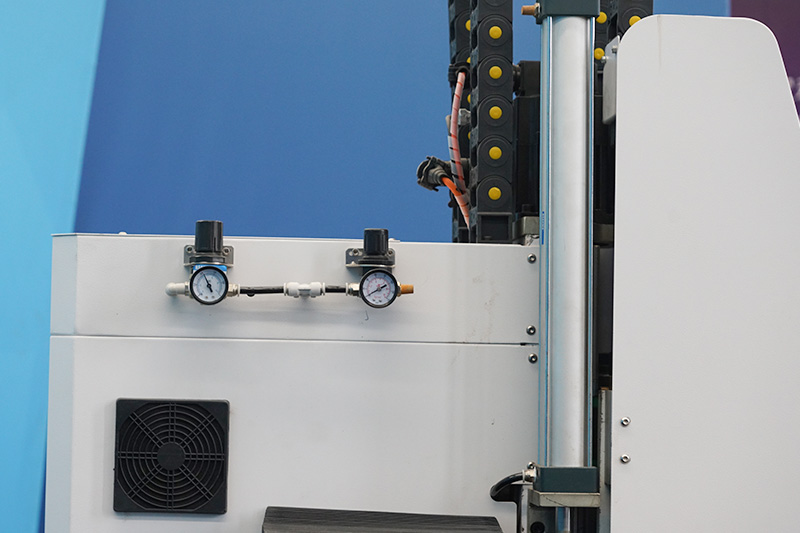

| Lubrication system | automatic lubrication system |

| Tool calibration | Autotool sensor calibration |

| Cables | Germany Igus cables with CE, cUL certificate |

| Command Language | G Code & M Code |

| Traveling speed | 60m/min |

| Working speed | 0-30m/min |

| Re-positioning accuracy | ±0.03mm |

| System resolution | ±0.0025mm |

| Working accuracy | ±0.03mm |

| Working voltage | 220V 1PH/ 3PH 50HZ/ 60HZ 380V 3PH 50HZ/ 60HZ |

| Working area | 1500x3000x300mm |

| Voltage | 380V/50Hz/3P |

| Spindle power | Shengfeng 5.5kWx2 water-cooled spindles |

| Control system | Ncstudio 95A-3S |

| Motor and driver | 1.5kW Dongling |

| Reducer | Shimpo |

Click for details

Spindle

Lubrication system

Balance cylinder

Tool sensor

Click for solution

Click for quotation