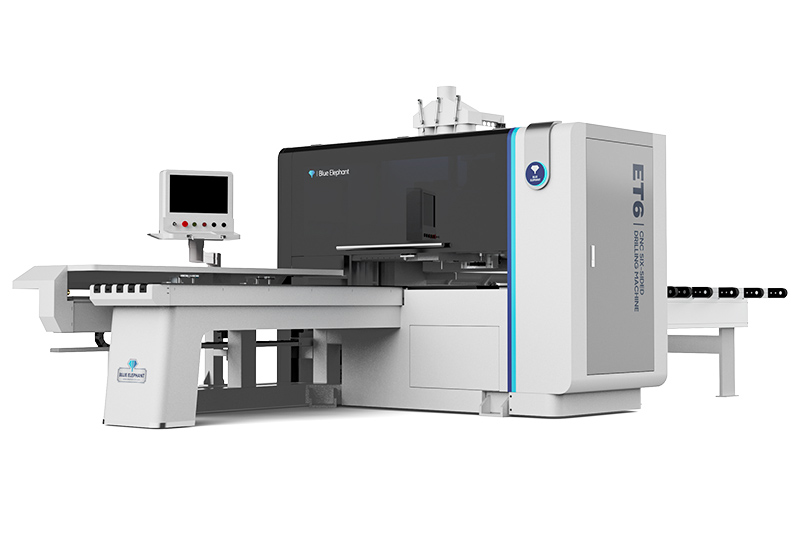

Six Sided ATC CNC Drilling Machine

Six-sided CNC Drilling Machine

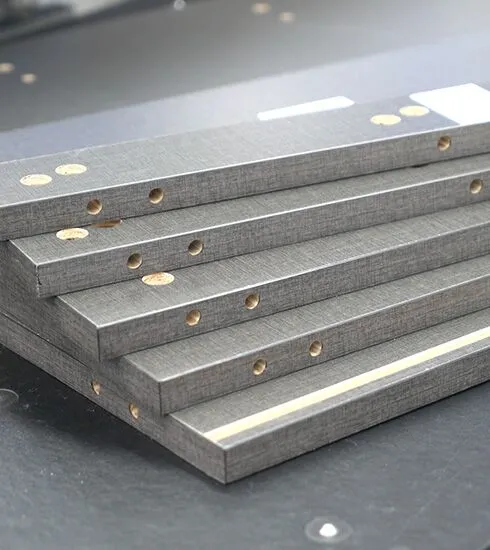

This automatic six-sided CNC drilling machine has wireless code scanning and automatic sorting functions. At the same time, the cnc drill automatically positions and loads materials, achieving one-time six-sided processing, front and rear groove processing. It has high processing efficiency and high degree of automation, suitable for industrialized production of panel furniture

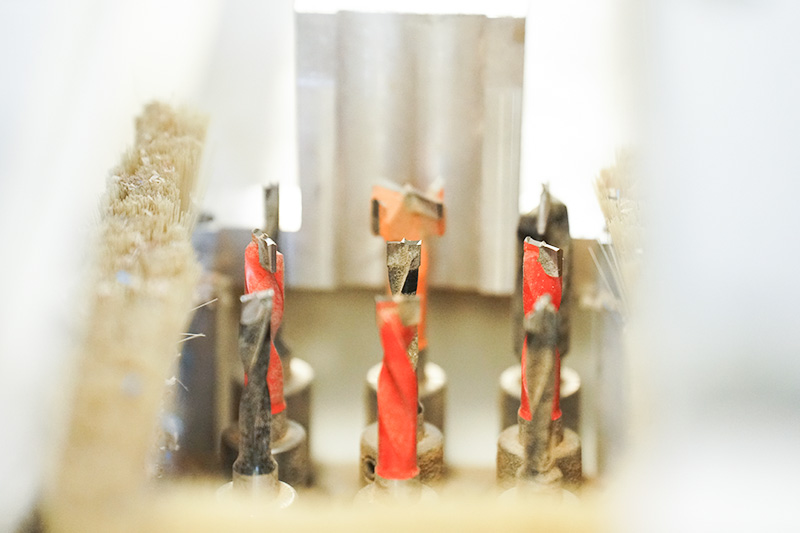

1. With an original skin breaking function, the 6 sided CNC drilling machine can achieve smoother punching and maximize the yield rate of the plate.

2. It adds a return table . Only one worker is needed to load and unload materials, the operation is simple and fast, saving worker costs.

3. It can automatically optimize and adjust the direction of the plate to achieve front and back discharge.

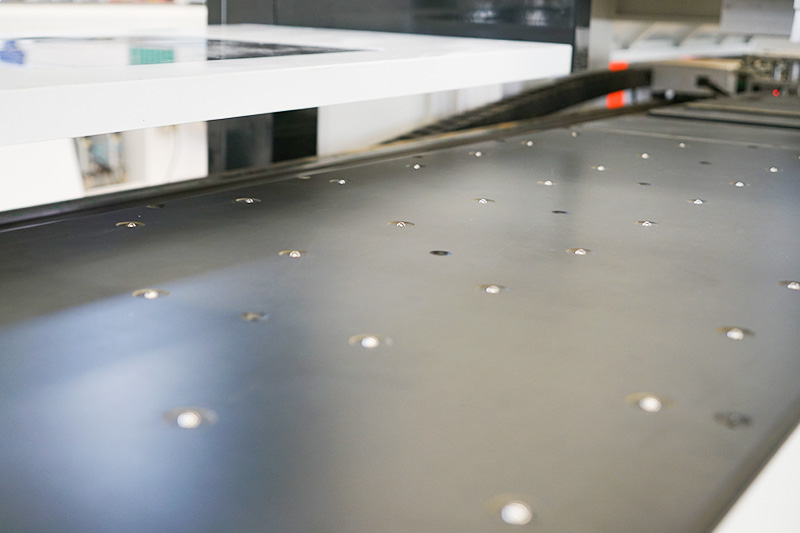

4. Air-floating worktable is adopted to achieve precise processing.

5. Dual drive can greatly improve the slotting and punching speed.

| Model | ET6 |

| Working size: | 1300x2500mm |

| Spindle type | 2*3.5KW HQD |

| Number of tools | 12 Vertical top drilling+8 horizontal drilling +9 bottom vertical drilling |

| Control system | Blue Elephant Custom System |

| Driver system | Absolute servo motor |

| Rack | JT rack |

| X axis travel speed | 120m/min |

| Y axis travel speed | 80m/min |

| Re-positioning accuracy | ±0.03mm |

| Software | Blue Elephant Custom System |

| Working voltage | 220V /380V/ 50-60HZ |

| Machine overall size | 5832*2727*2367mm |

| Table structure | Air floating table |

| Guide rail | Taiwan guide rail |

| Lubrication system | Automatic lubrication |

| Reducer | Shimpo |

| Inverter | Hpmont |

Click for details

Air floating table

Control handle

Drill tools

Pneumatic clamps

Click for solution

Click for quotation