Functions of E70JDSC Side Hole Drilling and Edge Banding Machine

Pre-separation→ pre-milling→ gluing→ welting→ end cutting→ rough trimming→ fine trimming→ tracking chamfering→ manual scraping→ side hole drilling→ flat scraping→ post-cleaning→ double polishing

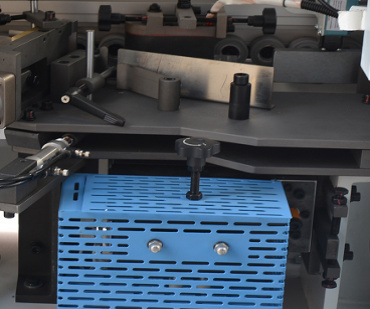

Pre-milling

Milling the edges and residue on the cutting surface of the plate to make the glue amount more uniform and the glue lines smaller.

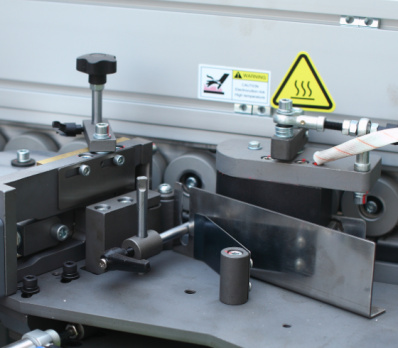

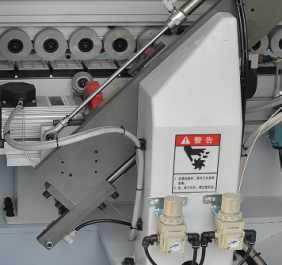

Gluing

Fast melting glue reduces the time cost, which greatly improved the gluing efficiency.

Welting

Selected the best suitable rubberized bearings can effectively and evenly glue the panels, allowing the edge banding tape to fit more closely without gaps.

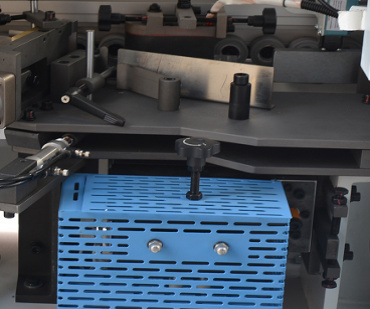

Six-wheel pressing

Multi-point contact and close pressing mak the edge banding tape and the board more adherent.

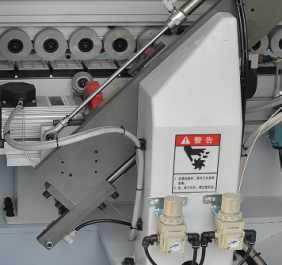

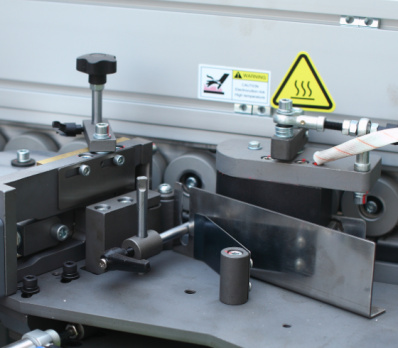

End cutting

Precisely cut the excess edge banding tape on the front and rear of the board, making it much cleaner and more tidy.

Rough and fine trimming

Cut the excess edge banding on the upper and lower sides of the panel through rough trimming and fine trimming, making it parallel to the panel.

Tracking

Use profiling tracking and chamfering to align the cutting edge so that it has no rhombus and the R angle of the entire board is consistent.

Scraping

To make the four corners more of the plate refined and smooth after edge banding.

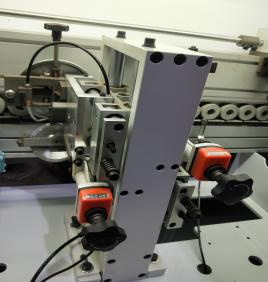

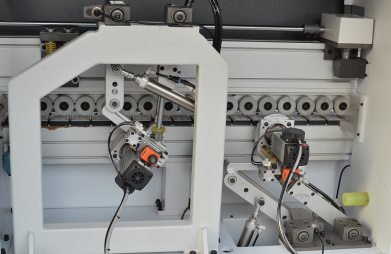

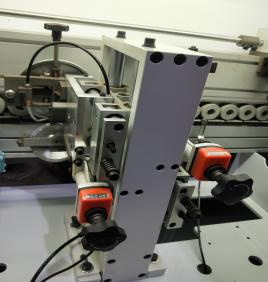

Hole driling

It can also accurately and fastly drill side holes in the edge banding tape at the same time, saving the cost and space of purchasing another side hole drilling machine. In addition, it is very suitable for use with the CNC drilling and cutting machine to improve the efficiency of furniture production.

Double polishing

Polish the board after edge banding to make the upper and lower sides of the edge banding tape smoother and more beautiful.

Parameters of E70JDSC Side Hole Drilling Edge Banding Machine

| Model |

E70JDSC |

| Machine Weight |

3500kg |

| Machine Size |

9250*960*1750mm |

| Total Power |

21kw |

| Air Pressure |

0.6MPa |

| Feed Speed |

16 - 23m/min |

| Panel Width |

≥60mm |

| Panel Thickness |

9 - 60mm |

| Panel Length |

≥60mm (no premilling) |

| ≥200mm (premilling) |

| Minimum Size |

60*60mm |

| Edge Banding Thickness |

150*200mm (premilling) |

Pros of E70JDSC Side Hole Drilling and Edge Banding Machine

Small footprint

The size of this fully automatic edge banding machine is 9250x960x1750mm and the weight is 3500kg. It occupies a moderate area and is easy to move.

Strong edge banding ability

The minimum edge banding size that can be processed is 150mm*60mm*10mm. The maximum thickness of the board that can be edge-sealed is 60mm, the length is 150mm and above, and the width is 60mm and above. The edge banding thickness is optional from 0.4mm to 3mm.

High edge banding efficiency

The feeding speed can reach 23m per minute, which can meet the edge banding efficiency of most customers.

High degree of automation

The E70JDSC synchronous side hole edge banding machine has automatic feeding, automatic edge banding and other automation functions, which greatly improves operating efficiency.

Easy to operate

The operation interface is intuitive and easy to use, equipped with a touch screen control panel. Ordinary employees can operate it after one hour of training.

Safety and environmental protection

This edge banding machine has a high safety factor and is equipped with emergency stop buttons, safety sensors, etc. to ensure user safety during operation. In addition, it adopts low energy consumption design and complies with international environmental protection standards.

After-sales service and warranty

Blue Elephant provides after-sales services, including training, maintenance, parts replacement, etc. The warranty period of the edge banding machine is one year.

Wide applications

The products are suitable for panel wardrobe cabinets, whole house customization companies, hotels, and office furniture companies.

Applicable Material & Edge Banding Type

Materials: medium density fiber board (MDF), blockboard, solid wood board, particle board, polymer door panel, plywood, etc.

Edge banding type: Straight edge banding, curved edge banding, special-shaped edge banding, etc.

Applications of E70JDSC Side Hole Drilling and Edge Banding Machine

Furniture manufacturing industry

Furniture manufacturing is one of the most important application fields of the side hole boring edge banding machines. When producing furniture, it can be used to process the edges of boards to make the furniture surface smoother, more beautiful, and increase durability.

Construction and decoration industry

The side hole drilling and edge banding machines are also used in the construction and decoration fields to process the edges of various decorative materials, such as wall panels, floors, doors and windows, etc.

Woodworking industry

Whether making wood products or wood crafts, the E70JDSC automtatic side hole drilling edge bander can be used to process wood edges to improve the quality and appearance of the product.

Office furniture manufacturing

When producing office furniture such as desks, filing cabinets, and conference tables, the E70JDSC drilling and edge banding machines can be used to process the edges of boards to improve the appearance and durability of the product.

Commercial Customization Industry

In the production of commercial customization products, the edge banding machine for drilling holes also play an important role as they are capable of handling various sizes and shapes of boards.

Generally speaking, any industry that needs to process the edges of panels to improve product quality, appearance and durability is likely to use an edge banding machine. The wide application of these machines makes the production process more efficient and the quality more stable.