On November 15, 2023, guests from Algeria came to Jinan Blue Elephant CNC Co., Ltd. for an on-site inspection visit. Andy, the sales representative of the foreign trade department, warmly received the guests from afar.

Before the customer arrives, we have prepared fruits, candies, drinks, etc. in the conference room in advance to receive the customer. In addition, we also prepared the product brochures, business cards and some small samples to facilitate customers to better understand Blue Elephant CNC.

After the Algerian client arrived, we first arranged for the client to sit down in the conference room. And then we explained to him how the general visit process is conducted. For example, we will first arrange him to visit the company environment, and then go to the factory to visit the machine manufacturing process and processing demonstration. If he doesn't agree, he can make corresponding adjustments according to customer preferences.

After a brief familiarization and conversation, Andy showed the client the prepared PPT, which contained the main information of the factory and company, as well as product renderings, etc. The customer has a very good impression of Blue Elephant and feels that we are very trustworthy. So after lunch, we took the customer to Blue Elephant’s Jinan factory.

Blue Elephant has two major factories, one in Tai'an and one in Jinan. Since Jinan is more convenient, we took the Algerian client to visit this factory in Jinan. This factory has more than 4,500 square meters, exceeding 80% of its peers. It is enough to show that Blue Elephant Company has strong strength in R&D and manufacturing CNC machine tools.

The customer is engaged in the furniture industry, so he is very interested in Blue Elephant furniture manufacturing equipment and panel furniture production lines. During this period, Andy walked with customers all the way, introduced product information to customers in real time, and provided corresponding samples to customers. At the same time, the company's technical department conducts product testing and performance introductions for customers on site.

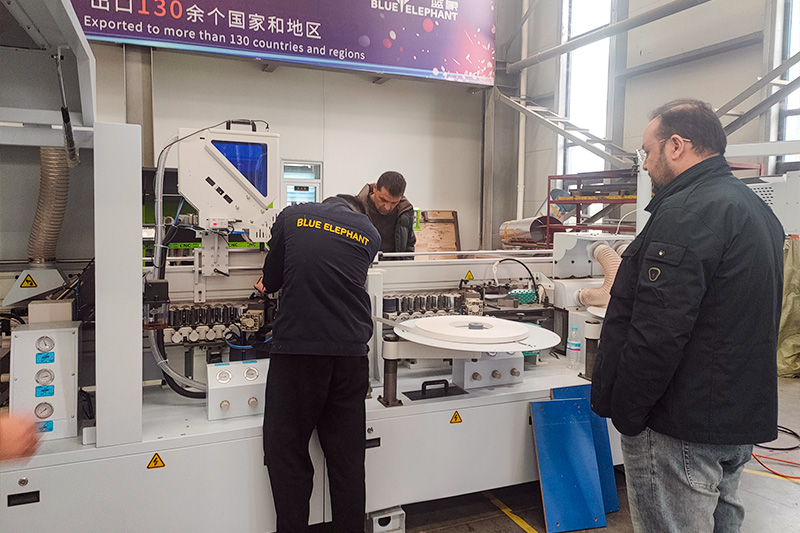

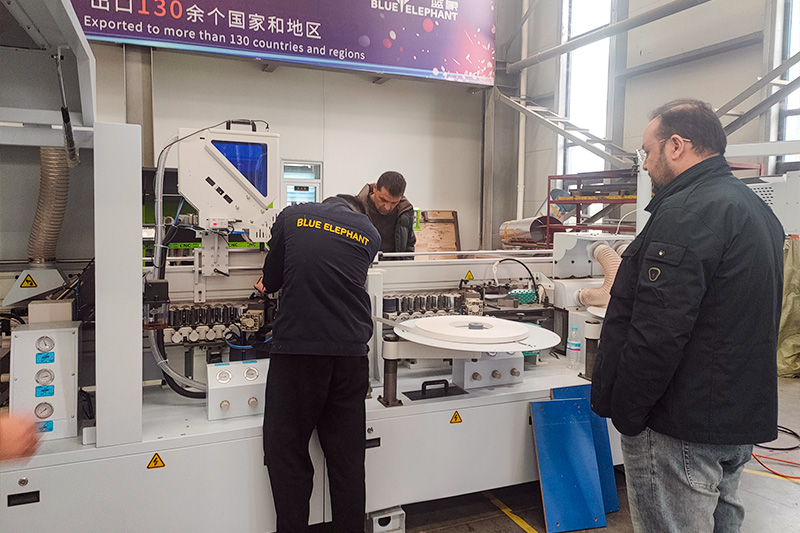

First of all, customers have a very strong interest in edge banding machines. So we explained and demonstrated to customers one by one, starting from the edge banding machine. Blue Elephant's edge banding machines are mainly divided into three categories: manual edge banding machines, semi-automatic edge banding machines and fully automatic edge banding machines. Among them, the best-selling and most efficient one is the Blue Elephant fully automatic edge banding machine (gluing pot, double glue pot, PUR cleaning glue pot). In order to allow customers to feel and understand the operation of our machines more intuitively, our technicians have conducted edge banding tests on different plates for customers. And while ensuring customer safety, we guide customers to try the operation themselves. All it takes is a few button presses and no complex training is required. The customer was very surprised. Not only was the operation simple, but the edge sealing effect was also so perfect. So he asked to visit furniture production equipment with other functions, such as drilling machines and cutting machines.

Since there are many types of cutting machines, there is not enough time to show them to customers one by one, so according to the customer's preferences and processing requirements, one of the most suitable ones is selected and shown to them. The customer said that the cutting speed of the board can greatly save their processing time and produce more furniture products, which is what he urgently needs. In addition, customers also learned and understood CNC six-sided drilling equipment and side hole machines. Although the six-sided drill is superior in all aspects, due to a limited budget, the customer planned to purchase a side-drilling machine first.

Finally, we also showed our customers more professional and advanced furniture production lines: cabinet processing production line and cabinet door processing production line. This production line covers all CNC equipment for manufacturing furniture, including cutting, drilling, engraving, polishing and other processes. Realize fully intelligent processing from beginning to end.

The whole process lasted until 4 o'clock in the afternoon. In the end, the customer fully affirmed the product quality and the company's strength, and established a long-term purchasing cooperation relationship. We hope that both parties can establish a long-term cooperative relationship and seek common development.

As the leading brand of CNC machine tools in China, as more and more foreign guests visit, Blue Elephant Company will continue to control product quality and bring better products and services to customers.