3015 Quartz Stone CNC Machine Center

Quartz Stone CNC Processing Center

This newly designed lightweight quartz stone processing center integrates cutting, edging, polishing, drilling and slot milling. The linear 12-tool magazine and the enhanced mechanical automatic tool change spindle have more outstanding automation, and various processes from hole opening, edging to polishing can achieve highly automated processing. This granite cnc machine solves the problem of high-end processes being time-consuming, labor-intensive and costly in the production process of stone countertops. It is currently widely used in the processing of stone countertops such as kitchen cabinet countertops, bathroom countertops, coffee tables or dining table countertops.

1.The dedicated quartz stone processing center system integrates CAD, CAM, and CNC, making human-machine exchange more friendly: you only need to know simple CAD drawing to easily draw directly on the software.

2.The process steps are modularized, grinding and polishing can be processed by simply filling in the process parameters. The operation is simple and no professional programmer is required.

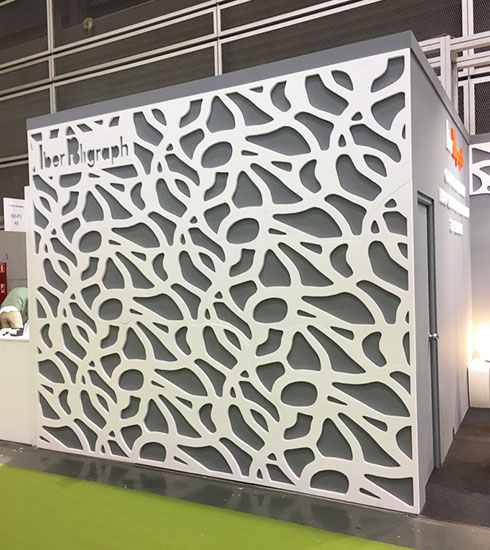

3.Powerful functions: Roman edge, rear arc water retaining, special-shaped cutting and other processes can be completed by one machine.

4.Automatic tool change: No human intervention is required during the processing, and the operator can perform other work.

5.Self-circulating water system: The stone cnc router is equipped with a circulating water tank, and the whole machine can realize self-circulation. It only needs to change the water and clean it regularly. If there is a sedimentation pool inside the factory, it can be used in combination.

| ES3-3015E | ||

| X,Y,Z axis travel | 3000*1500*300mm | |

| Traveling speed | X axis | 30m/min |

| Y axis | 30m/min | |

| Z axis | 15m/min | |

| Servo motor | X axis | 1.5KW(Leadshine) |

| Y axis | 1.5KW(Leadshine) | |

| Z axis | 1.5KW brake(Leadshine) | |

| Guide | X axis | 30(Domestic HIWIN) |

| Y axis | 30(Domestic HIWIN) | |

| Z axis | 30(Domestic HIWIN) | |

| Rack | X axis | 2M(PCRCH) |

| Y axis | 2M(PCRCH) | |

| Lead Screw | Z axis | 3210(Domestic) |

| Reducer | X/Y axis Japan Shimpo reducer | |

| Spindle | SOHA GS150-BT40-11KW liquid-cooling ATC spindle 18000 rpm | |

| Shank | BT40 | |

| Water cooler | CW5000TI | |

| Tool magazine | Double linear tool magazines, 12 pieces in total | |

| Control system | WEIHONG NC65C quartz stone machining center system | |

| Table | PVC(1500*3000*30)+double-sided suction cups*8 | |

| Vacuum pump | Water circulation pump 5.5KW (standard) | |

| Low voltage electrical appliances | DELIXI | |

| Inverter | ZONCN 15KW | |

| Working air pressure | 0.7-0.8Mpa | |

| Voltage | 380V/3P/50HZ | |

| Total power | 27KW | |

| Machine size | 5500*2600*2250(With shassis) | |

| Weight | 3tons | |

Click for details

Quartz Stone CNC Machining Center

Click for solution

Click for quotation