1.Reverse Modeling

1. Can not program which four axis linkage.

2. After ArtCAM software installation is successful, always appear alarm, click yes or no can be ok. Because after Autodesk's acquisition of ArtCAM, put ArtCAM sale online support site to shut up, so always alarms.

3. Non-Axisymmetric model is not suitable for rotation axis in Artcam to make program.

4. Artcam support of all 3D model formats.

Commonly used for the STL, step, igs

1. Four axis linkage need special post-processor for machine

1. Fusion360 take into account the problem of piracy, it is encrypted before publishing, customers need to buy a permit to use this software online, if customers need create a post processor (Fusion 360 does not have a corresponding post processor) will need to provide the machine configuration and G code format to manufacturers, pay for changes.

2. Website of post processor to fusion for corresponding brand control system.

https://cam.autodesk.com/hsmposts?_ga=2.148965685.2061918116.1546518503-2018726694.1533724494

3. Not only to support the three-axis, four-axis also supports five-axis, no cracked version

https://www.autodesk.com.cn/products/fusion-360/overview

Trial version supports 3-axis, the official version can made 5-axis tool path.

1. M code is related to the auxiliary functions of the machine, such as M03 is spindle forward, M04 is spindle reverse, M05 is spindle stops, M08 start cutting fluid (open oil mist cooling), M09 close cutting fluid, M30 program back to start point after finish machining, M02 pause program.

1. Woodworking cnc router can not directly use files with the extension ".ai".

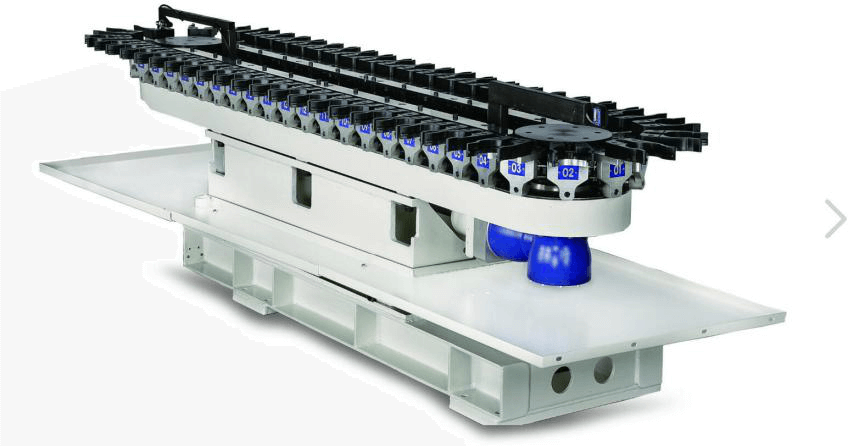

2. Our linear tool magazine ATC, we can use TopSolid software.

3. Output file which format is "eps" or "AI", input to Coreldraw, though export Coreldraw output dxf file, and then input into ArtCAM software, generates G-code with ArtCAM. Pdf can not.

4. Does ArtCAM and UG software support "STEP" or "IGES" files? File with step format can be opened with PRO-E software, file with iges format can use Solidworks, Cad, CAXA which have drawing function software. ArtCAM support both two formats.

5. Download free CAD and 3D design software | Free Trial | Autodesk https://www.autodesk.com.cn/free-trialsThis is the official website of Autodesk, until now, customers are asked most of the software belong to Autodesk, as well as belong to Vectric. It can also be seen ArtCAM stop selling. It can also be understood can not downloaded. So we need send ArtCAM software if customers need it.

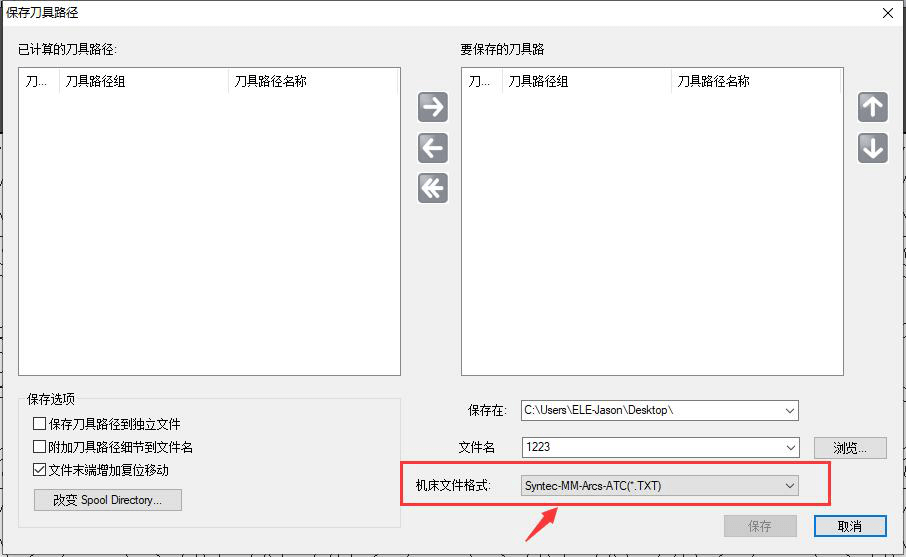

6. In the beginning stages of development of CNC machine tool numerical control system since there is no uniform standard, so different manufacturers and different brands, have different corresponding G code format. The effect of the post-processor is to be processed is converted into what the machine can read code --- G codes / machining program, so different brands control system (Siemens, Syntec, etc.), require corresponding post-processor to generates a corresponding machining program.

7. Vientiane NC Super linkage (Vientiane) software (a small minority of engraving software, support rotation four axis linkage, require special software to output four axis linkage program, but no 2D program), can not replace artcam. Vientiane program only output rotary program, the other programs can not be output.

8. CAM software can be converted STL file to G code.

9. Artcam and UG

Artcam and UG and they are two different software, the output file format which they output itself is different, such as the artcam default file format is ".art", "art" is artcam proprietary file format, but UG default file format is "prt", "prt" UG is a proprietary file format, they can not be universal, artcam proprietary file format can not lead into UG software. But UG and artcam can read some common file formats, such as: "stl", "igs" ,"step", "stp", and so on.

1. How to Judge a software if available in English.

Check software is developed which country, if it is developed abroad 99% will be in English. If you are domestically developed, it may not have an English version.

2. Customers want to avoid drawing mistakes in his work, before the machine is running what work needs to be done or how to avoid; does have relationship with this system, such as control panel, can we preview tool path or others?

Some systems with simulation, we can see the processing path, also can simulation before machining. Like versions of dsp A5x big screen series, the Syntec all version, all versions of LNC, Siemens version.

Inventor HSM and HSMWorks CAM by CAD software embedded 2.5 to 5-axis milling, turning and milling - turning functions simplifies machining processes. Only centralized provides product design and manufacturing software.

1, The adaptive Cleaning: compared with the conventional roughing, reduce the time by more than 4 times, and prolong the tool life.

2, CAD / CAM integration: Inventor or use familiar tools and user interface of SolidWorks software.

3, Inventor of AnyCAD: the source CAD system design changes will be automatically updated to downstream drawing and toolpaths.

4, Toolpath need a short time to calculate: multi-processor/multi-core CPU can be reduced toolpath calculate time, this is especially true for large or complex designs.

5, 2.5 axis machining: 2D plane processing strategies. It included in the free Express version, HSMWorks, inventor HSM and conventional versions.

6, 3-axis milling and 3 + 2 positioned: choose from several 3-axis styles, or select a plane work, use the same CAM policy execute 3+2 axis positioning.

7, Multi-axis operation: Using simultaneously 4 and 5-axis machining complex model functions, including multi-axis contouring machining and 3D toolpaths tilt.

8, Turning and milling - Turning: by a conventional turning, surface machining, grooving and drilling functions to improve productivity. Support dynamic Milling - Turning.

9, Water jet, plasma cutting machine and laser cutting: by adding all the contours in the same plane, add clamping projection and adding specified quality setting, can quickly generate a 2D contour cut path.

10, Detection: automatically avoid collision parts and tool holder in the CNC calculation process.

11, Tool chuck avoid collision: include tool holder to prevent a collision in tool path calculations, we can choose opened, trim, tool length detecting when a collision occurs or suspension

12, Engraving shapes and text: engraving using chamfering tool shape or text part.

13, Slope process: by using a tool engaged to control the slope angle, so as to minimize deformation of the tool and improving finish.

14, Blank and tool path simulation: check blank to be moved, examination axis and gripper/ fixture if collision.

15, Edit CNC output: perform common text editor for NC program files.

16, Analysis tools: measuring distance or dynamic view important information, such as feed rate / speed and the estimated processing time.

The ARTCAM can not multi-axis programming, but more good in terms of processing relief

Function of post processor is to change toolpath can be recognized on the machine "language" (Code G) to achieve the pattern - Production toolpath - through post processor processing -- G code - machining.We buy dongle to UG and POWERMILL, we used to call it "post-processing", but in fact it is a RTCP function, which is only used in multi-axis machining. It should not be confused with the software's own post-processor. RTCP, in the upscale five-axis CNC control system, think "RTCP= Rotated Tool Center Point", that is, we often say that the tool tip follow function.

1. Marco is a underlying file format to control machine moving.

2. The more output pulses per unit time of the theoretically, the higher the control accuracy.

http://www.richnc.com.cn

1.

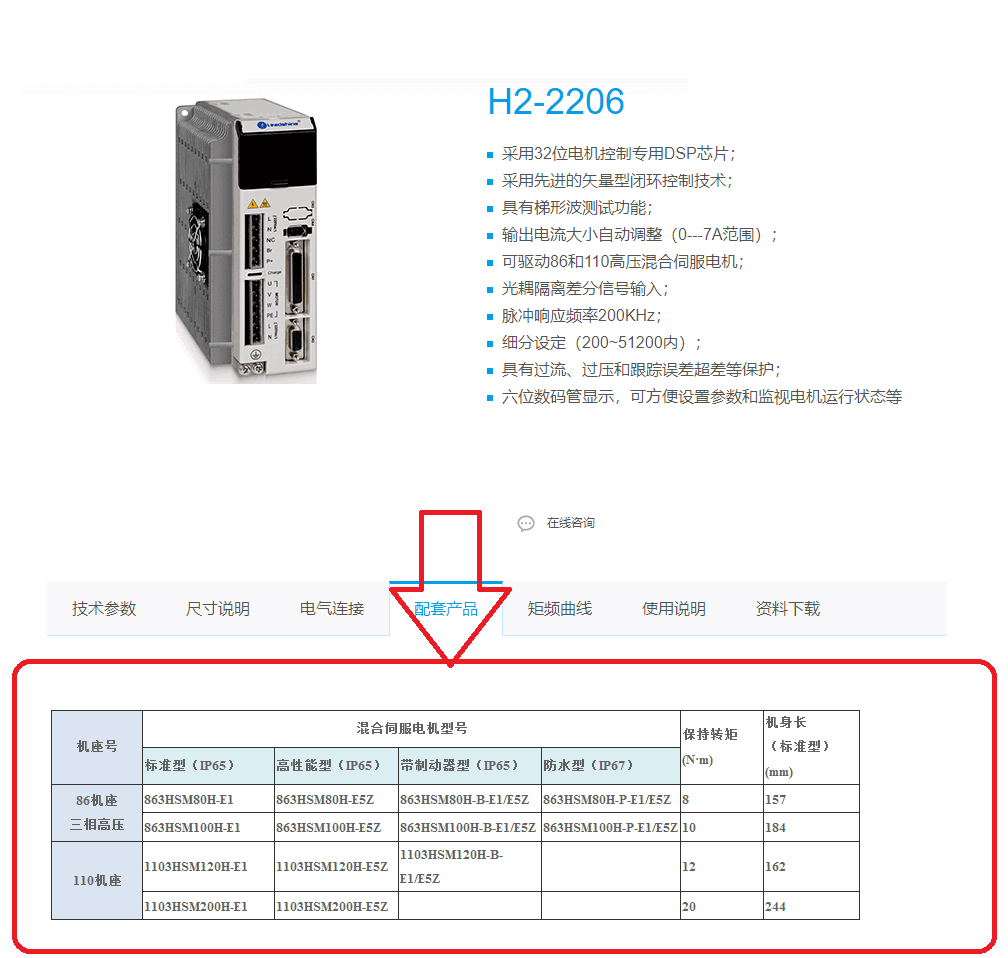

2206 is often with the 86 motor.

2206 is often with the 86 motor.2. DSP A11 RAM is 512MB.

1. Does mach3 support linear tool magazine ATC + cradle version five-axis?

No. 200MA-5A can be used or 220MA-5A.

3000mm / min 200

3000-8000mm / min 300

> 8000mm / min 400

Mach3 speed may not exceed 8 meters per minute(8000mm/min). Because mach3 cab not sharp turn

ELE1212 generous tube + FL118 +Leadshine + Mach3, cut wood with a 10mm milling cutter, the maximum speed can be adjusted to 15,000mm/min or 18,000mm/min.

1. Question: Four-axis Mach3, customers want to transform X-axis and Y-axis, can we change by software?

Answer: Line on the drive to change what you can. By software change the dir pin 2 and 4, steppin 1 and 3 to change it.

Question: Does our Mach3 have this license, customers wanna know if have permission in North America?

Answer: Mach3 license no regional restrictions. As long as the computer is not Apple systems and windows 8 system. License name is the default name can not be changed.

1. Have many compensation parameters in Nc studio(Weihong) control system, improve the parameter compensation to improve accuracy, but these parameters are obtained by measuring the external equipment after the compensation and go. How to improve accurate?

https://v.youku.com/v_show/id_XMjk0MjU1Mzg0MA==.html?spm=a2h0k.11417342.soresults.dposter

2. NC studio(Weihong) system name

1. Weihong(Nc studio) PM95A system 3L series, the third process. Necessary to choose 3Cyinder

1Converter Config (3 cylinder and 1 inverter).

2. 95A-3L and 95A-3S:

95A-3L (Not support hand wheel), and 95A-3S (Support hand wheel) is a small I/O board: Lambda3L and Lambda3S, have four outputs points, the expansion card can not be added, max can be made four operation cnc router; 95A-3A is large I/O plate Lambda4s, there are 8 output points, we can also add an expansion card, can make four operation cnc router, linear tool magazine, carousel tool magazine, drill row, and so almost all the three-axis; 95A-4A is a four-axis linkage movement system.

1. The Syntec of visual positioning system (camera), The customer must manually mark the parts to be processed by the new generation of visual positioning. Then the vision positioning system scans the mark, locates the workpiece position according to the mark, and automatically corrects the position error of the workpiece and the error of the design value.

1. 6MB and 6MD difference:

6MB sub-line , 6MD bus.

Bus version advantages: highly integrated circuit, space-saving, less self interference, Suitable for long distance wiring.

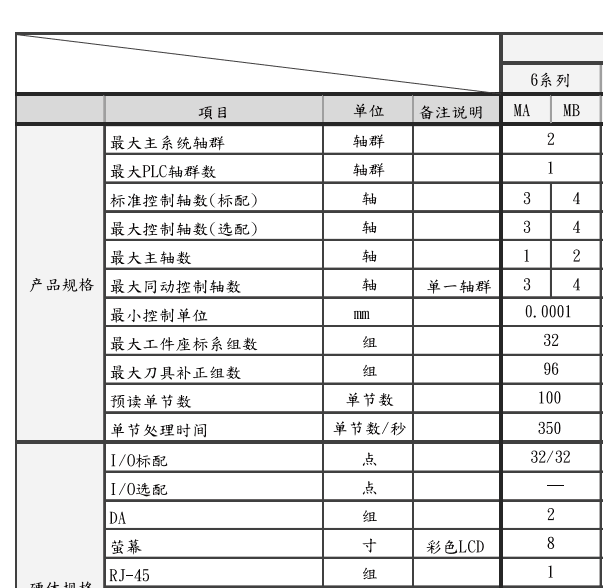

The Syntec of 21 MA is a high functional. IO points is three times than 6M series, IO points can add more also can add more device. 21MA supports up to six axes. can same times control 4 axis move, 6 axis 6 linkage. The new generation of 21MA standard with HPCC.

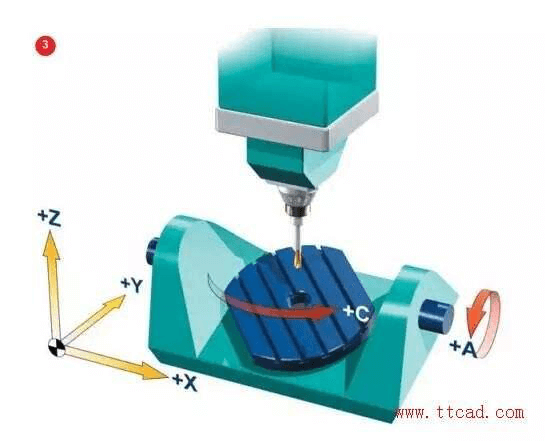

1. Syntec fourth axis can also be called the A-axis B-axis, C-axis can also be called. This can be changed in the control system. But it must be before the factory

2. Syntec 6MA is 3 axis 3linkage, 6MB four-axis four linkage.

3.

1. Siemens 808D, support ATC, does not support oscillation knife.

1. LNC 5800A supports 3 axis ATC, the processor can be use syntec’s.

http://www.cslhjd.com/

1. Ethernet interface, have English version. Desktop or laptop can be ok. windows system

Syntec, Siemens, Weihong handle, PM95A series, NK panel series, DSP handle.

DSP handle (X8 requires the use of open ports, machine parameter setting → input port configuration parameters, process will pause if it be occlusion)

In addition to Syntec,Siemens Weihong panel series, the others need to install additional foot switch.

https://planet-cnc.com/planetcnc-tng-software-overview-and-performance-guidelines/

Can be used in CNC machine acts as Mach3, and like Weihong

4-axis support

https://www.centroidcnc.com/centroid_diy/acorn_cnc_controller.html

1. ATC + 9 + Vertical drilling + automatic loading and unloading + automatic labeling machine, want to use cab master program, this software can we support? Does it support automatic layout during automatic labeling?

No crack version, with this software, we can not use UCancam, this software can not only render the design, it can also be programmed. We need to modify the code part after drilling made out.

2. ATC four axis machining aluminum and wood can reach 0.02 / pulse resolution

3. 0.6mpa < x < 0.8mpa (1mpa = 10psi = 10bar) nominal displacement (Air compressor exhaust volume refers to the amount of air of standard atmospheric pressure that the air compressor takes in per unit time) : ( Displacement) 0.63m3 / min air reservoir tank: 180L is generally recommended election of 5.5kw or 7.5kw vacuum pump.

4. Australia MASSO system, we can use on ATC machine.

5. Knife handle: BT30 difference with/without keyway.

Keyway effect: When machining metal, to ensure that the handle does not slide inside the spindle.

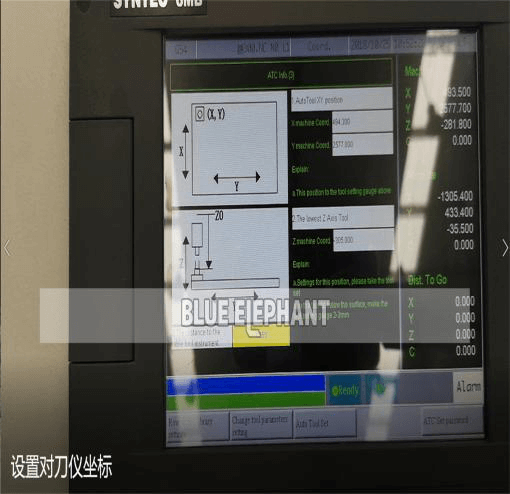

The two coordinate interface, set which one both ok. Set this one, the other will be automatically updated.

1. Oscillation knife can’t with drag knife

2.

3. TCM-4 Oscillation knife, can adjust cutting pressure, cutting thickness, can turn, can not oscillate, rip the workpiece.

1. 2.2kw water cooling spindle Model: 2.2kw water cooling spindle built three bearings: two 7002 and one 7005.

2. Only 9kw ATC spindle bearings are ceramic. The others are steel to made. At present most of the automatic tool change is NSK, manual tool change is GMN, NSK.

3. 3kw Changsheng water cooling spindle current is 7A.

4. Chang Xu 3.5kw ATC water cooling spindle speed, it can be made 24000rpm, 30000rpm can also.

1. 9kw 220v / 380v HQD Spindle: 38A / 22A

1. 2.2kw spindle, 2.2KW is maximum constant and normal power, influenced by the spindle speed, cut depth and cutting speed.

2. Central outlet water spindle: 1) Spindle support center outlet water. 2) Tool support center output water.

3. Spindle load said torque. 9kw tool spindle can be maximum weight is 0.88kg.

4. How do we know whether the spindle is damaged?

1) not turn 2) turn on spindle have significant noise 3) the spindle speed less than 24,000, we can check the inverter,if inverter display 400, it reached 24,000.

5. Horizontal installation of main shaft, double spindle general use 3.5KW changsheng air cooling spindle, we also can choose 3.2KW HQD air cooling spindle (collect ER20 and ER16) and 4.5KWHQD air cooling spindle. we default to the customer double 3.5KW changsheng(CS) water cooling spindle, cost-effective, also use a long time, relatively stable.

6. 2040 one spindle with 3 axis and one spindle with 6 axis distance of spindle problem. Answer: One spindle with 3 axis working range is 62cm, one spindle with 6 axis working range is 32cm. Two side of one spindle with 3 axis distance is 38cm, two side of one spindle with 6 axis is 20cm.

7. 9kw HSD ATC spindle one time cut 19mm MDF maximum speed is 12m/min, the production order write 9kw.

8. Can we add a dust removal part on spindle?

Please click under link to check specific device role,

https://rangate.com/products/tornado

Answer: we can add.

This device is not safe, if this part fall in machining, it will hit the spindle or tool, cause some damage.

The dust on the cutting surface can be sucked out, and most of the dust is still on the workpiece.

Recommend use dust collector, suck dust into bag.

1. Add row drill on 3 axis ATC machine, EOT-3, TCT-1, which system can support that.

Syntec 6MB, oscillation knife and pressure roller can not used same time, it is not very convenient.

2. 11MB support EOT, TCT, can add the rotary device, up to support 8 axis, up to 4 axis synchronization.

3. 21MA bus-version oscillation knife’s driver can not connect with system.

True four-axis machine capable of processing a mold below the glass fibers, can used MDF, after process the mold and attach the fiberglass layer by layer, such as bath model, car hood model, some medical device model.

1. Object with open top,tool can go straight up and down without using the four-axis. When processing the outside, we can turn him upside down. However, the upper axis will block the lower axis that needs the four axes, but if the arc above will not block the parts that need to be processed below, the four axis will not be needed.

2. The position at the 90-degree corner is a very typical one: four-axis three-link action, three-link means that three axes are moving at the same time, and the system controls three axes at the same time.

The action at the 90-degree corner is: the rotation axis rotates, the z-axis rises, and the x-axis moves to the right. The above three actions are performed simultaneously.

1. The rotary axis plug of normal machine and plus movable rotary axis is a four-axis system which can be made independent, and three-axis ones are common.

2. The rotating shaft alternately connects the two machines for welding and independent plug. Unplug it and plug it in. It is better that the two machines have the same system.

3. What can we do with our minimum diameter chuck rotary device?

Diameter and length complement each other. For example, if the length of the customer's wood is 1 meter, the minimum diameter of the wood is about 60mm. If the length is half a meter, the minimum diameter of the wood is about 45mm.

Beijing Vientiane there is a software specifically for the axis of rotation, rotation axis and the other axis to achieve linkage function. https://item.taobao.com/item.htm?spm=a1z10.1-cs.w4004-18978794570.3.5bb3f43cPJ8yMo&id=567019631080

(The picture shows the cradle with five-axis, non-AB swing)

Each axis defined axis.

1. The axis of rotation around the x-axis is called the A-axis.

2. The axis of rotation around the y-axis is called the B-axis.

3. Three axes plus a five-axis head. Sometimes we call this device A / B pendulum. The existence of the c-axis causes the swing axis to sometimes rotate around the x-axis and sometimes rotate around the y-axis. Called AB pendulum.

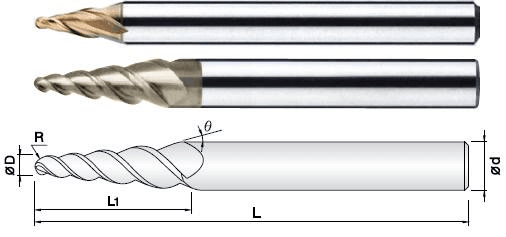

| sharp knife |  |

Conical ball nose cutter |  |

| Ball knife |  |

Double-edged spiral |  |

1. Generally, when doing relief or round carving, most of the time, the ball-nose knife is used in finishing. The smaller workpieces will use sharp or tapered ball-nose knife, but the flat-blade knife will never be used in finishing.

Standard roughing and finishing processes video: https://www.youtube.com/watch?v=dcKq08oLQBw

1. We need modify PLC when we add oscillation knife and relay.

Can we add drag knife in our cnc router? Customer wants to cut polyester fiber, the drag knife can cut it?

Yes, we can. similar to a stool, in principle, it is turned by external force.

https://www.youtube.com/watch?v=edivb-mzxIA

1. Use the 20 tool to change the head, while for tool magazine recommended use the servo motors.

2. This part of the disc tool changer is a pressure regulator.

It generally not used in our machines

1. Customers use such materials, processing chair, do you have to use true four axes? Height is 900mm.

Bending first then cut, need use five-axis. First cut and then bending, three-axis can

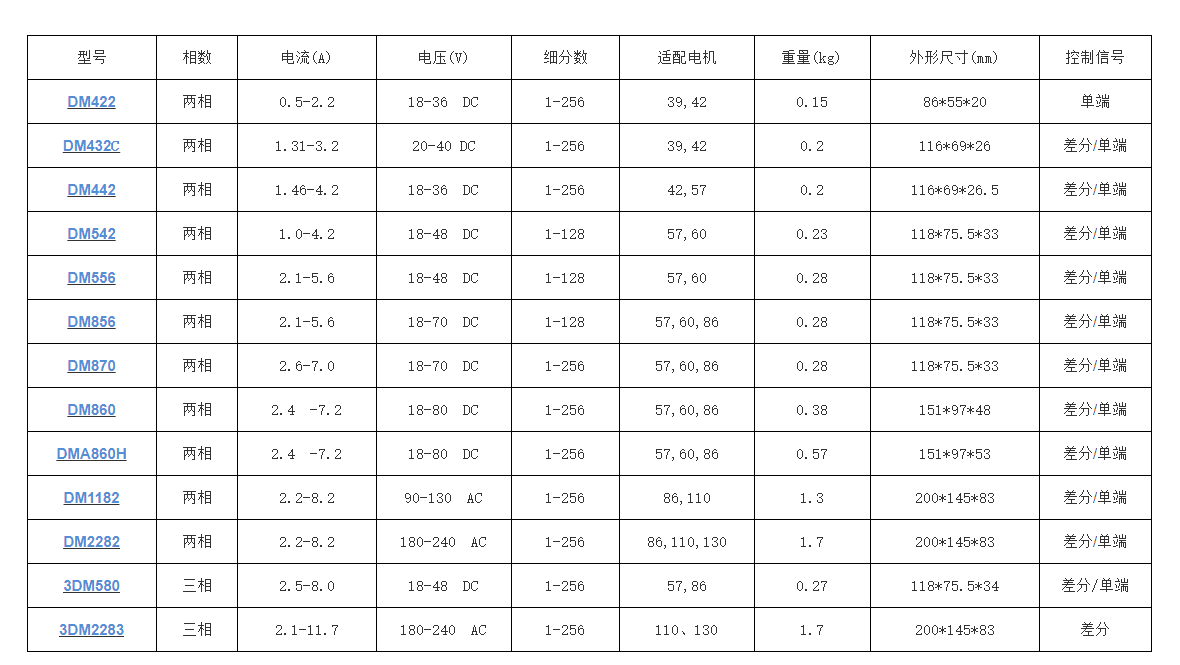

1. Leadshine 750W servo belong HBS series,

2. ND2278 has been discontinued, the upgrade is Dm2282.

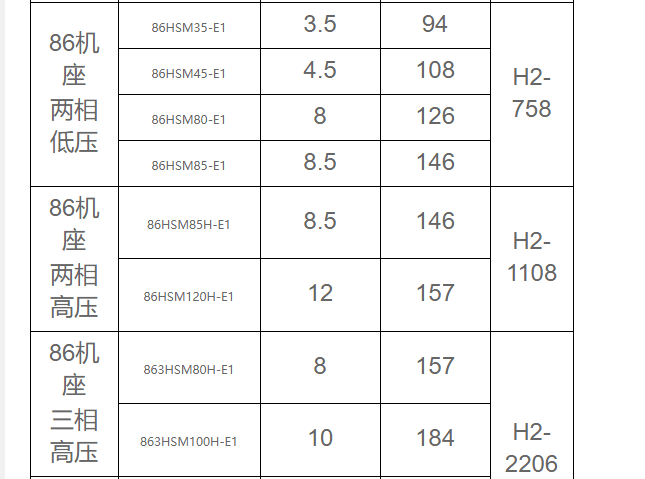

1. HBS758: This machine had more after-sale problems are more, motor is hot and easy to burn the thread.

2. H2-758 is an upgraded version. The software's algorithm is different, the other is no different.

1. We used Sigma7 driver and motor (Sigma SGM7G)

2. If Yasukawa 410 alarms, need return for repair.

1. U.S. standard, NEMA17=motor42, 23 =motor57, 34 = motor 86.

2. with closed loop stepper motors (not DC servo) loop stepper motor, not a easy servo.

3. It is recommended to use a servo motor for the three steps of horizontal mounting of the intermediate spindle.

4. seemingly servo motors are brushless motor.

5.

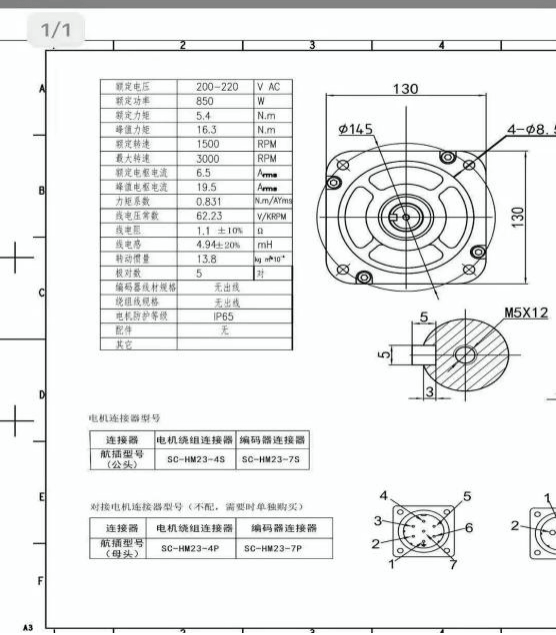

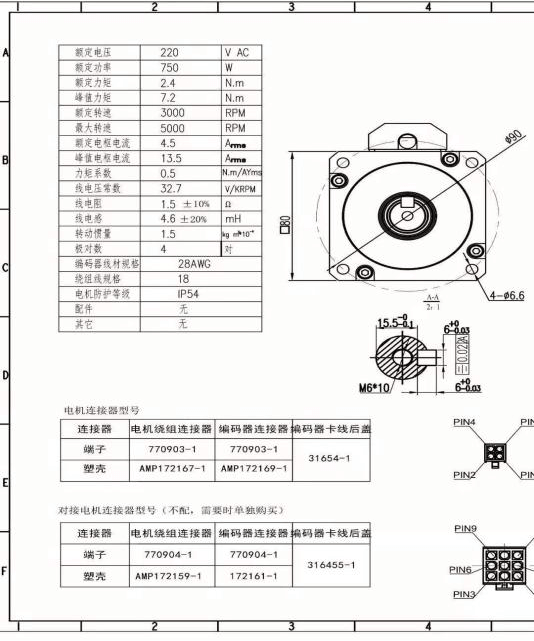

6. Leadshine servo motor instruction parameter, torque, speed, current and voltage parameters.

7.Leadshine easy servo motor torque,as follows(86)

1. VFD075E23A should 7.5kw E-type

1 kilowatt (KW) = 1.341 horsepower (HP inch) 1 kilowatt (KW) = 1.36 horsepower (PS Metric)

1 horsepower (HP inch) = 0.7457 kilowatts (KW) 1 horsepower (PS Metric) = 0.735 kilowatts (KW)

1 horsepower (HP inch) = 1.014 horsepower (PS Metric) 1 horsepower (PS Metric) = 0.9863 horsepower (HP inch)

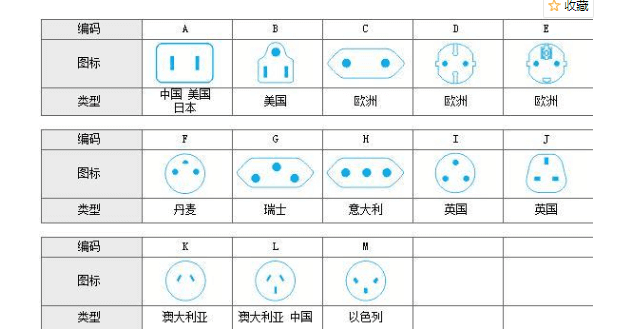

1. Specific national standard voltage and plug Daquan, own a small partner please download the technical exchange group

2.

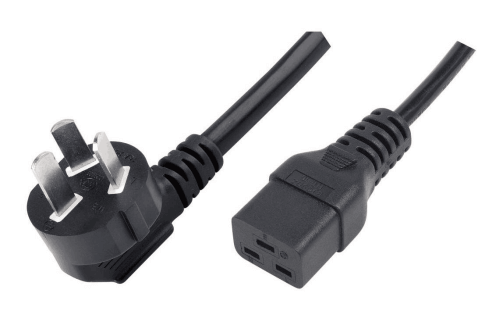

This type of plug and wire together can generally withstand a small current, which is generally about 10A.

When the rated current of the wire is exceeded, the heat generation of the wire will rise sharply, and the wire may be burnt and cause a fire.

The spindle 3kw belongs to high-power electrical appliances. It is not recommended to use this type of plug and wire together. You can buy a plug and wire it yourself, or this type of terminal block wiring in our factory will do.

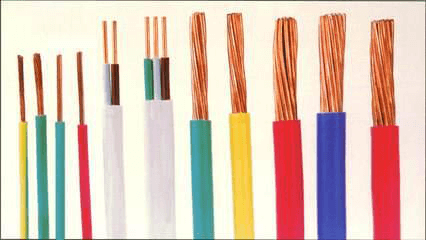

Oneness wire

Oneness wire

This is reasonable, because

This is reasonable, because

we can choose wires specifications.

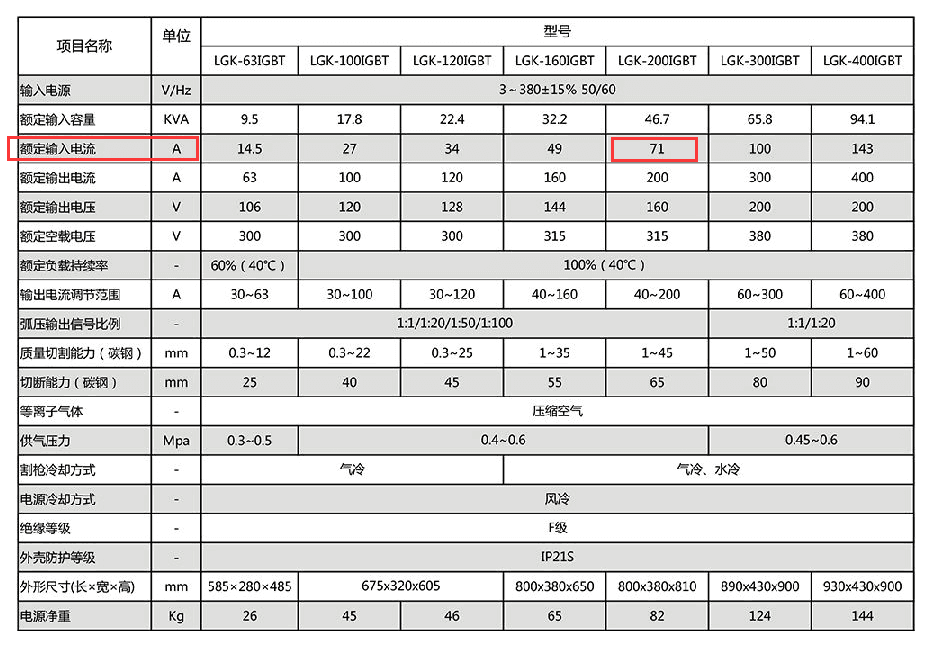

Rated input (maximum) current of Huayuan welding machine

Customers purchase power cords based on this

1. Check if the customer's power line voltage exceeds 220v (if it is a 380v machine. See if it exceeds 380)

2. Check whether the z-axis return to zero is successful, and whether the z-axis screw is stuck.

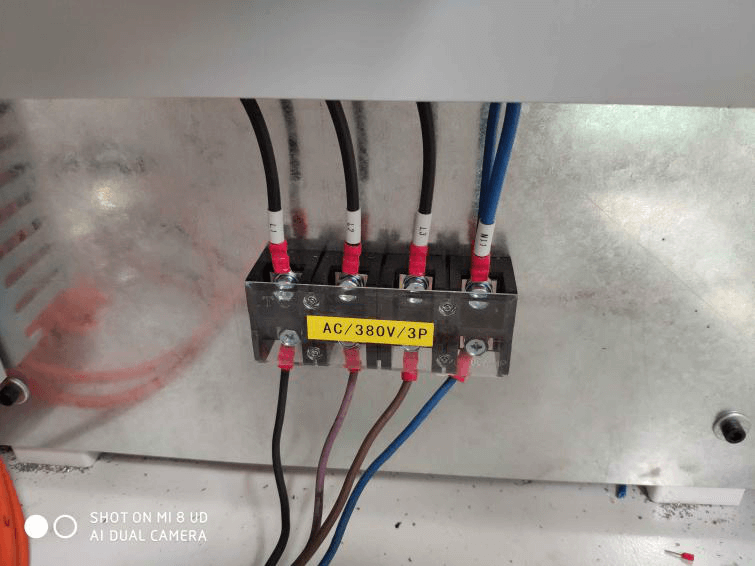

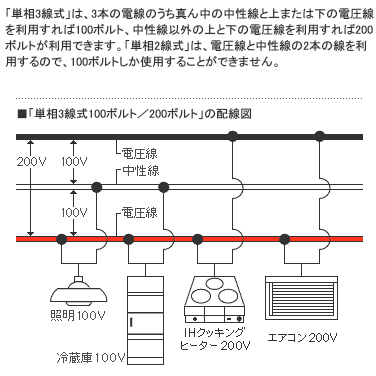

1. 380V 3ph:

1) It can be converted into 220v 1ph electricity without adding a transformer.

2) Transformer with 380V to 220V can transform into 220V 3ph electricity.

3) With 380V to 415V transformer, 415V 3ph electricity can be changed. Three items of variable voltage and number of items, but 220v 1ph electricity cannot be transformed into 380v 3ph electricity by a transformer. 220v 1ph electricity can be transformed into 110v 1ph electricity and 250v 1ph electricity by a transformer. The voltage can be changed by a transformer, but the number of phases cannot be changed. One item can only change voltage.

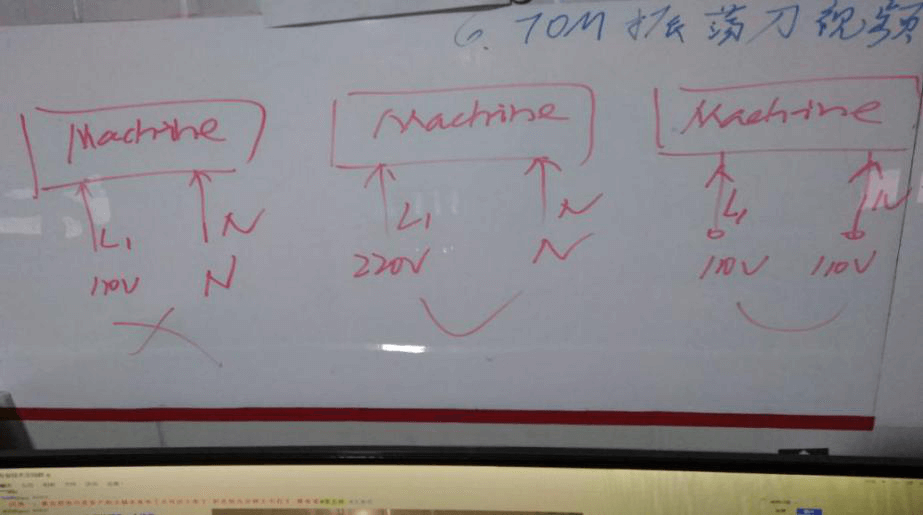

A voltage of 110 like the United States generally places a 220v single item, and then the customer can follow the wiring on the picture. The first type (in order from left to right) if not work, and the second or third type works.

1. There is no encoder on the drive, only on the servo motor. What is the role of the encoder on the motor? How far does the machine go? Is the encoder telling the system whether the direction is forward or backward? It’s a feedback element.

2. The resolution of Leadshine servo and Yaskawa servo refers to the number of encoders of the motor, not the driver. Leashine has a 23-bit encoder. Yaskawa has 20, 22, and 24. We use a 24-bit encoder. Motor accuracy: the difference between the actual value and the set value without external force. For rotary encoders (we use rotary encoders), it is generally defined as angular seconds or angular minutes. For linear encoders, the accuracy is generally micron, which is very small. It should be noted that high resolution does not mean high accuracy.

For example, two rotary encoders with the same accuracy, one has a resolution of 3600 PPR and the other has a resolution of 10,000 PPR. A low-resolution encoder (3600 PPR) can provide a measurement distance of 0.1 °, while a high-resolution encoder can provide a smaller measurement distance, but the accuracy of the two is the same. A high-resolution encoder is just Ability to reduce 0.1 ° to smaller incremental distances. The larger the resolution of the encoder, the smaller the distance that it is capable of measuring, but it does not mean that the accuracy of the actual measurement is smaller, and there are other factors.

1. The parameters of the automatic tool setting instrument on a true four-axis ATC machine can be set in the parameter interface and the tool setting interface, and the data will be updated simultaneously.

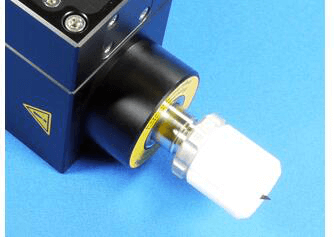

2. Laser tool calibration generally can be equipped with Siemens and new Syntec http://www.sczy.com/gallery-74-grid.html?audience=284829

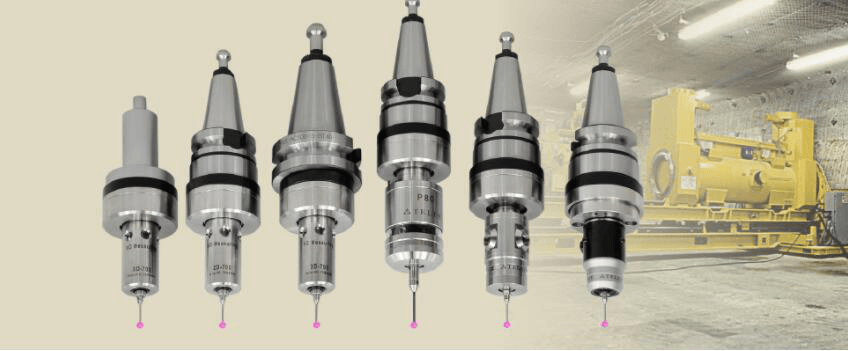

3. Can this machine tool probe be added to our ATC four-axis machine? If it can be added, do we still need to add a tool calibration on the machine?

This is to set workpiece zero point. It has nothing to do with the tool calibration. can add, but we not suggest add. Because it suit machining metal, not wood.

Common rotary shaft gear, the reduction ratio is 20: 1. There are also 40: 1 in stock. Contact custom design needs.

Large gear box reduction ratio 1: 3; large gear wheel 90, a small gear wheel 30.

Small gear box reduction ratio 1: 5; large gear wheel 90, the small wheel 18 teeth.

Modoli gear reduction ratio 1: 5;

shimpo reducer reduction ratio of 1: 8

1. Just add a reducer on the X axis, the Syntec 6MB system settings have not changed much, just need to modify the pulse. If the reduction ratio is the same, the pulse should not be modified.

2. Our rotary device reducer is planetary gear (we often called RV gear), rv75

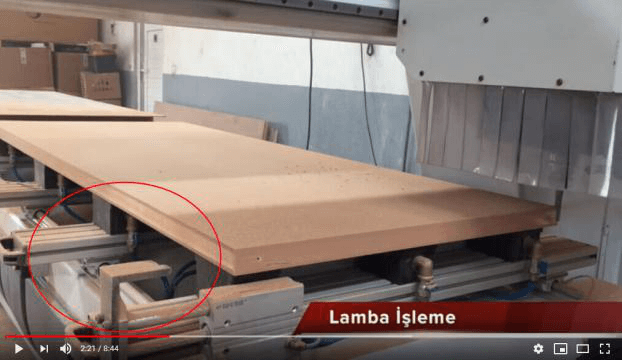

1. PTP row drilling

http://www.jnruiyefeng.com/products/lm3/140.html

Both countertop and tooling, our factory can do

https://www.youtube.com/watch?v=MJpEs1ENX3k&t=418s

1. Three operation cnc router, what is the minimum pressure of the air compressor when the middle spindle is installed horizontally?

ATC pressure range is 0.6 - 0.8mpa (1mpa = 10psi = 10bar), multi operation > 0.5

2. 0.5MPA = 500 kpa = 500 000 pa 0.5MPA = 5 (atm) = 5 (kg / cm2)

1. 3kw circulation pump suction is 0.18m³ / min

2. Measured current:

| 5.5KW | 220V3P | 20A |

| 380V3P | 15A | |

| 7.5KW | 220V3P | 30A |

| 380V3P | 18A |

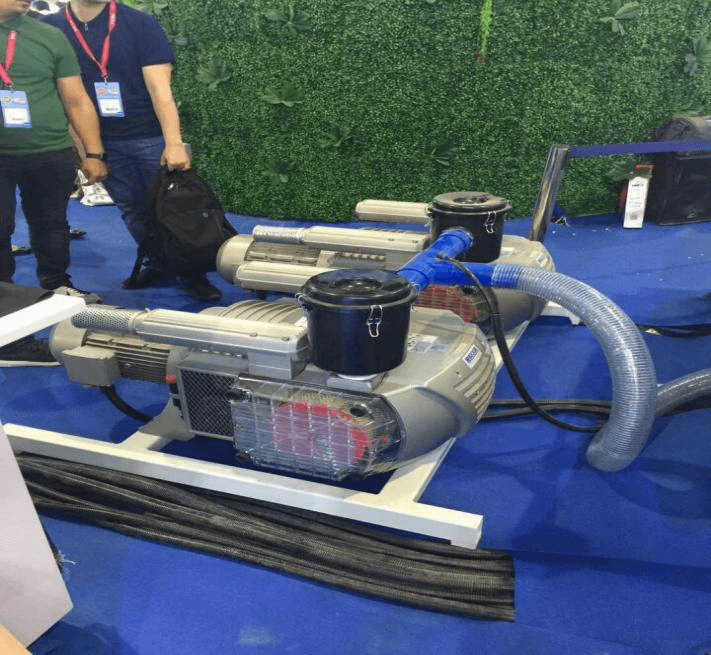

1. The customer requires the vacuum pump to be connected in this way. What are the advantages and disadvantages? Will the suction be particularly strong?

Suction will become stronger. But you need to add a check valve to each pump.

His header is relatively large in diameter and it can be connected in this way. This connection can be made but many things need to be changed. Specific need to find designer.

1. Machine stopped, fuel injection continued, how to stop manually?

① Cut off the gas source

② Turn off the spray switch. Siemens' spray switch is k12 or k7, and k7 is the key above k10.

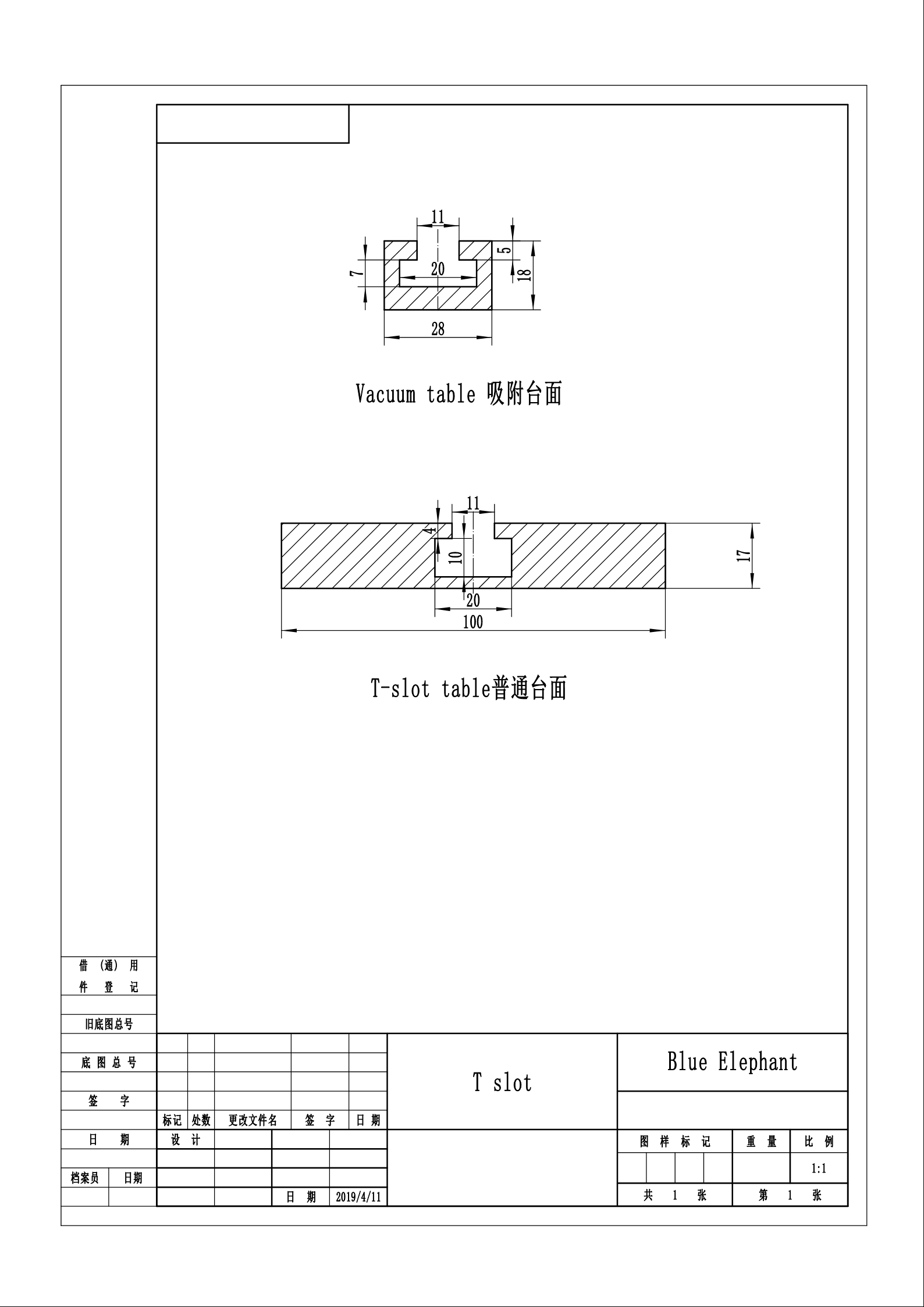

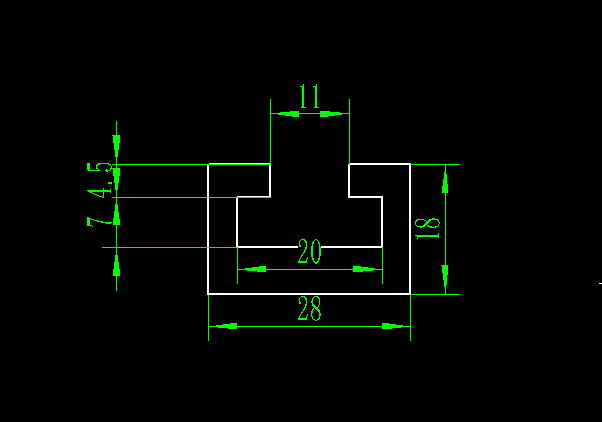

1. T-slot size

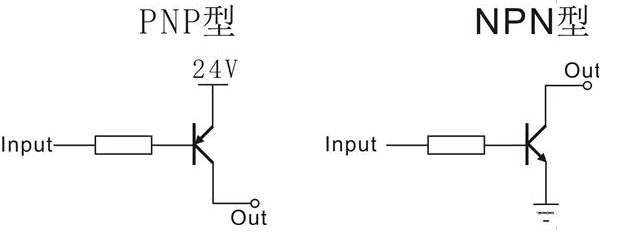

(Japan Omron limit is NPN)

The main difference is that the current direction and the voltage are different, which is the "polarity" problem:

1. NPN is to control the current of C → E (IC) by the current of B → E (IB). The E-pole potential is the lowest, and the C-pole potential is usually the highest during normal amplification;

2. PNP is to control the current (IC) of E → C by the current of E → B (IB). The E-pole potential is the highest, and the C-pole potential is usually the lowest during normal amplification. In NPN circuits, E is eventually connected to the floor, C is ultimately connected to the ceiling; PNP circuits, on the other hand, are ultimately connected to the floor, and E is ultimately connected to the ceiling. In general circuits, with NPN, you can get the PNP version by the method of "symmetric exchange up and down".

1. The probe should be used on a machine tool for processing metal. It is rarely useful like woodworking machinery. Most applications are for processing metal. For wood, different environments, such as dry and humid environments, may have large size differences. Can't achieve the effect

http://www.quating.com/ct/rmp60wxdct.shtml

2. The probe consists of a measuring head body and a stylus. The main body of the measuring head is installed on the main shaft of the machine tool. When the stylus contacts the object, a ring signal will be generated. The precision of the machine tool and the size of the detected workpiece are clearly visible on the digital display of the machine tool.

Specific reference links: http://www.exbomv.com/product_view_130_160.html

high torch control

https: //www.schmalz.com/en/applications/industries/wood/clamping-solutions/

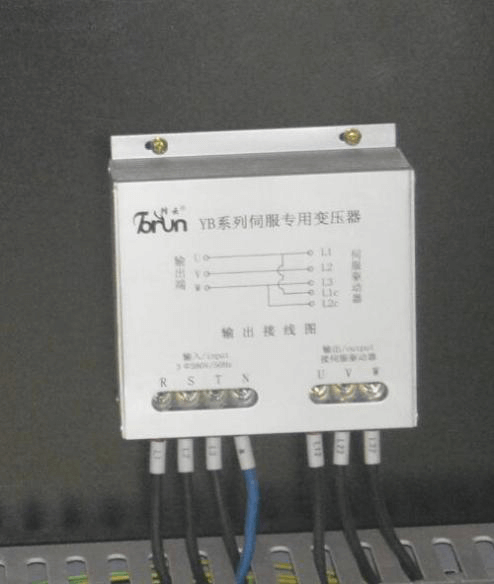

1. The customer voltage is 220v 3ph, the machine is 1325 plasma, 85A Haibao 270V, stepper motor and driver, 20KVA transformer is required

2. Commonly used transformer

Dry-type transformers advantages:

① Good insulation performance, no partial discharge and strong lightning shock resistance.

② Good mechanical strength, strong resistance to temperature changes and short circuit resistance.

③ Resistant to humidity and can run under high humidity.

① The secondary side of the transformer can output a constant amplitude voltage;

② The power quality can be improved, the input current and output voltage of the sine waveform can be obtained and the unit power factor can be achieved, and the voltage and current on both sides of the transformer can be controlled, so the power factor can be adjusted arbitrarily;

③ It has the function of a circuit breaker, and high-power power electronic devices can turn off the faulty large current instantaneously (within subtle time), eliminating the need for a relay protection device.

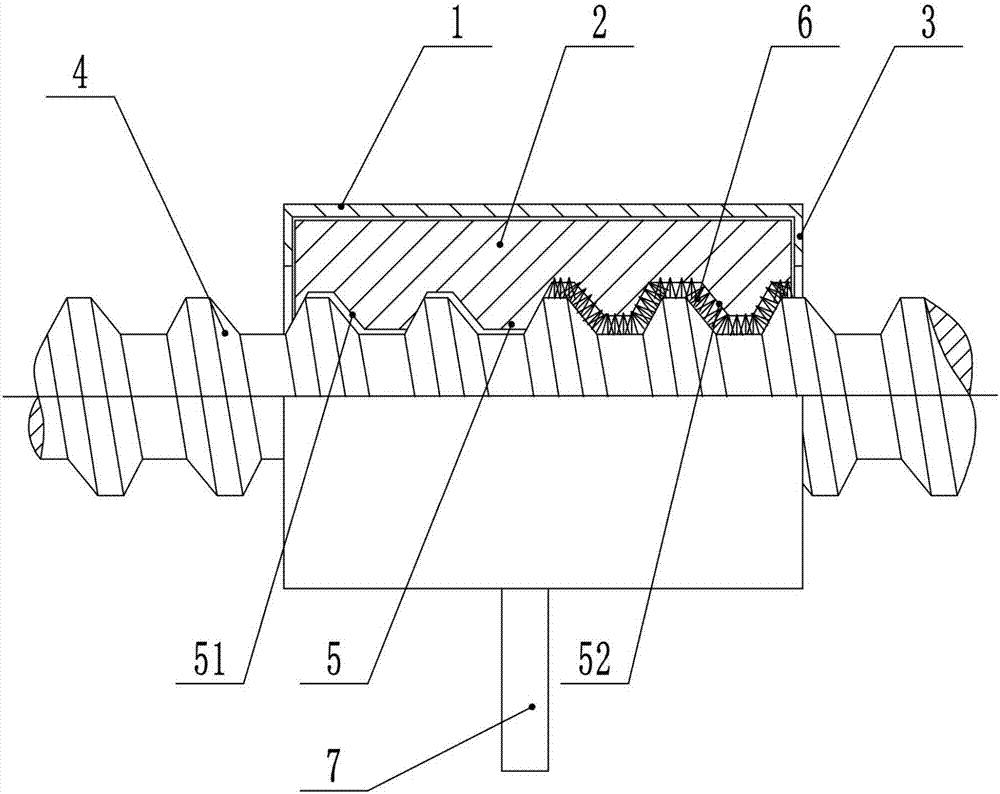

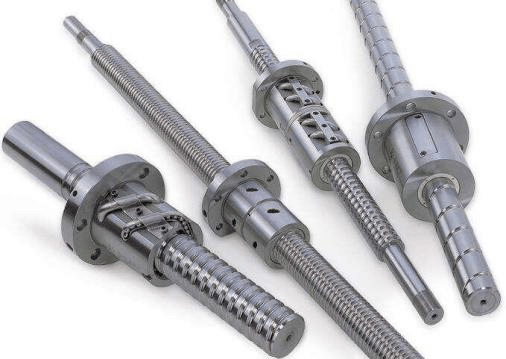

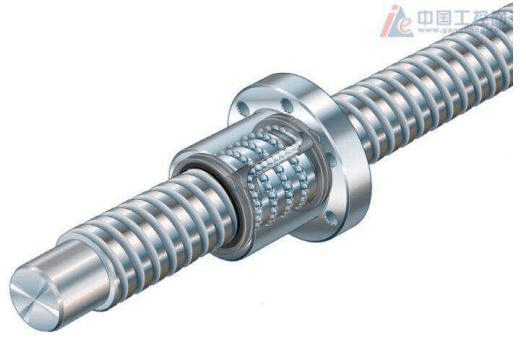

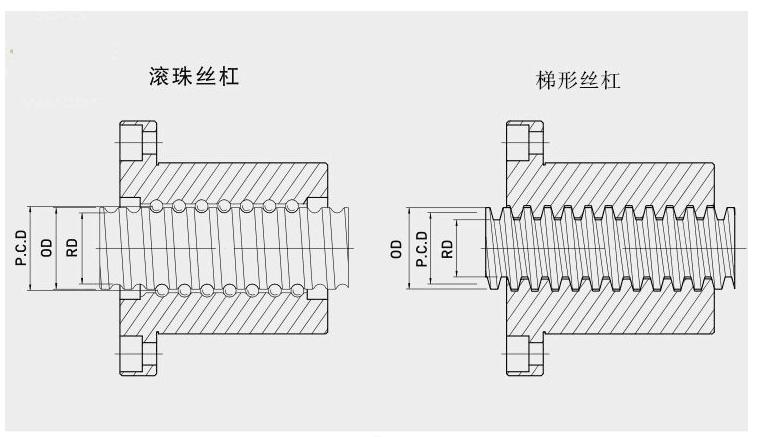

The TBI lead screw for the Z axis on ordinary ATC is a rolled type

The ground screw type should be called "T-shaped screw" in China

Trapezoidal should be called "trapezoidal threaded screw" is generally used on lathes or some semi-automatic machine tools. Suitable for heavy-duty and low-speed machine tools.

("Trapezoidal threaded screw")

("Trapezoidal threaded screw")

rolled type: it should be is our ball screw.

(Ball screw)

(Ball screw)

1. Can this glass fiber be punched with a side hole machine?

It seems to be, but the z-axis machine side holes seemingly not so large adjustment range.

1. Intelligent Vision laser cutting control system

http://www.rd-acs.com/products.aspx?TypeId=50107&FId=t3:50107:3

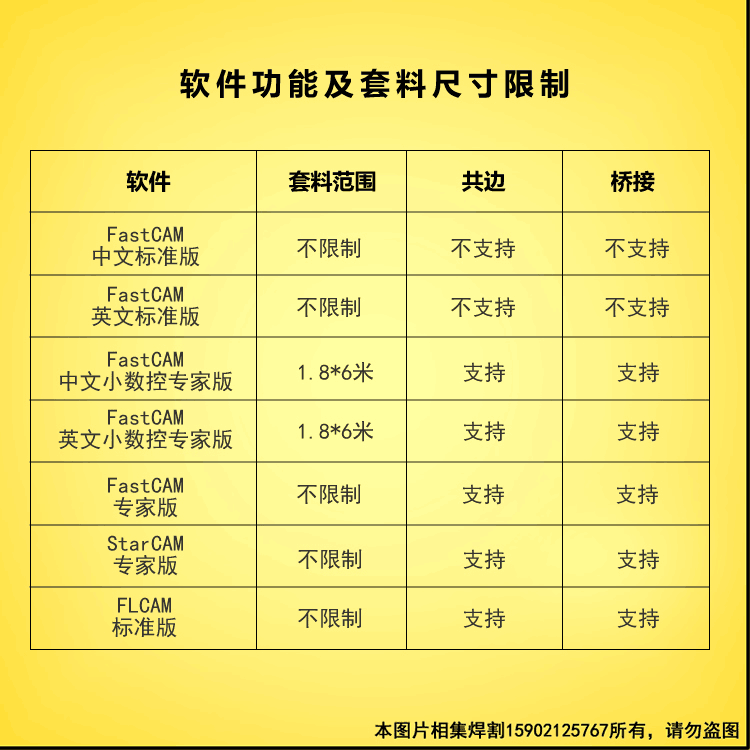

1. fastcam English version - Multi-language support Chinese, English, German, Japanese, French, Spanish, Korean, Russian, etc., suitable for export.

2. fastcam contains a software CD, dongle, Chinese instructions.

Fastcam generates general-purpose files, as long as it is Fangling's system. A dongle is required when using the software. The machine does not require a dongle

1. Gantry type plasma, the smallest effective processing size: width 2200, length 2000mm.

2. With Huayuan 120A power supply plasma cut3mm steel, need with 1.3mm or 1.5mm nozzle

1. Fangling 7000 supports up to six axis

http://www.flcnc.com/page91.html?product_id=62&brd=1&product_category=19

1. THC with the SH-HC30

1. The cutting of plasma power is divided into quality cutting and extreme cutting. Working at full load during plasma cutting will not cause any damage to the plasma power supply. However, the life of the plasma consumables will be much shorter than that of normal use.

2. Plasma cutting uses two-dimensional drawings. Customers can find pictures and draw them into drawings using drawing design software such as AutoCAD.

3. The reason why plasma requires an air compressor: 1) protect the workpiece, the molten metal will fly away, and will not solidify on the cutting surface, so that the cutting surface is smooth 2) the cutting gun is cooled 3) the molten iron filings are prevented from sticking to the cutting gun, Protection torch.

4. Plasma cutting machine system can use Siemens

5. Leiming laser

https://www.youtube.com/channel/UCP7h5jTJPweWw_CrQz3TTcA/videos

6. Bodor Laser

https://www.youtube.com/channel/UCcGEdcjanRwa3MkJbjJYXbg

Material Cutting speed recommendations:

1) 25mm melamine board (particle board) we generally use a 6-8 m / min three-blade straight groove knife with a diameter of 8mm

2) 18mm melamine board (particle board) is generally 10-15 meters / minute, it is recommended to be 10 meters, the faster the tool wears faster, the 8mm diameter three-blade straight groove knife cuts 18mm

3) 18mm ecological board (multi-layer board, solid wood panel) we generally 10-15 meters / minute, the recommended is 10 meters, the faster the speed of the tool wear faster, three-edge straight slotted knife with a diameter of 8mm

4) Our (our company) 's normal standard plate, as long as it is not a custom plate. Whether it is MDF, ecological board, or multilayer board. The length and width are standard: length 2440, width 1220 (the numbers without units are mm)

1. Use stone cnc router or saw to process 12mm fiber cement board, spindle needs to be 5.5KW, and the processing speed is about 2m / min. Processing capacity around 6mm

1. Pegasus fine type. Suitable for cutting aluminum plates, thin stainless steel, etc.

2. Plasma can process square tubes. There is a special system. We just haven't used them. Round tubes can be processed by rotating shafts.

1. What is the difference between 60,000 and 24,000 rpm processing acrylic, if the speed is high, the acrylic will melt. Polished acrylic, generally used in mobile phone stores to display mobile phone holders.

2. The surface of the acrylic board after cutting is first subjected to shaping, roughing, finishing, polishing paste, and fine finishing. The polishing wheel is super-finished. The cutting surface treated by these procedures is even higher than the surface finish of the board. Acrylic processing to this extent requires plastic roughing, finishing (which we can do with woodworking machines), polishing paste fine processing (which we can't do), and polishing wheel super-finishing (which we can't do).

3. Insulation board, less than 20cm thick, double-sided colored steel or stainless steel, is there a special machine for PU inside?

The manufacturer of Mach3 said no, but customers can install it later because they need to write marco, which means: tell the machine how to perform this knife setting action. Our Mach manufacturer should have no corresponding Marco. Pu color steel sandwich panel equipment, there is special equipment to do this thing is called pu color steel sandwich panel.

4. ep is a type of plastic, epoxy

https://baike.baidu.com/item/ep/2643946

https://image.baidu.com/search/index?tn=baiduimage&ct=201326592&lm=-1&cl=2&ie=gb18030&word=%CB%AB%C9%AB%B0%E5&fr=ala&ala=1&alatpl=adress&pos=0&hs=2&xthttps= 111111

1. Engine oil is divided into single-viscosity engine oil (such as SAE30) and multi-viscosity engine oil (such as SAE5W-30). Most vehicles now use multi-viscosity engine oil, because this engine oil contains a variety of special additives, which makes the engine oil easy in low temperature Flowing, non-condensing, maintains consistency and does not decompose in high temperature environments. W in the engine oil label represents Winter, and the number before W indicates the low-temperature fluidity of the engine oil. The smaller the number, the better the fluidity of the engine oil. Engine wear is mainly concentrated at the moment of cold start. Good oil fluidity can minimize engine wear. The number after W indicates the high temperature viscosity of the engine oil. The larger the number, the better the protection performance at high temperature.