1. Hand type scanner need a computer with high configuration, at lest win7, two RAM (Each one is at least 8G) , Graphics card must use Nvidia (preferably 1050 upwards)

2. Hand type 3D scanner not support MAC system. This brand scanner only is Windows system, Nvidia graphice card. MOst of apple’s imac computer is A card (AMD) , Nvidia is N card, can’t support this brand hand type scanner. Apple's notebook is temporarily unclear.

3. Scanner not support computer offline work

https://baike. baidu. com/item/3ds%20max/272324?fromtitle=3dmax&fromid=3236629&fr=aladdin

http://www. zbrushcn. com/

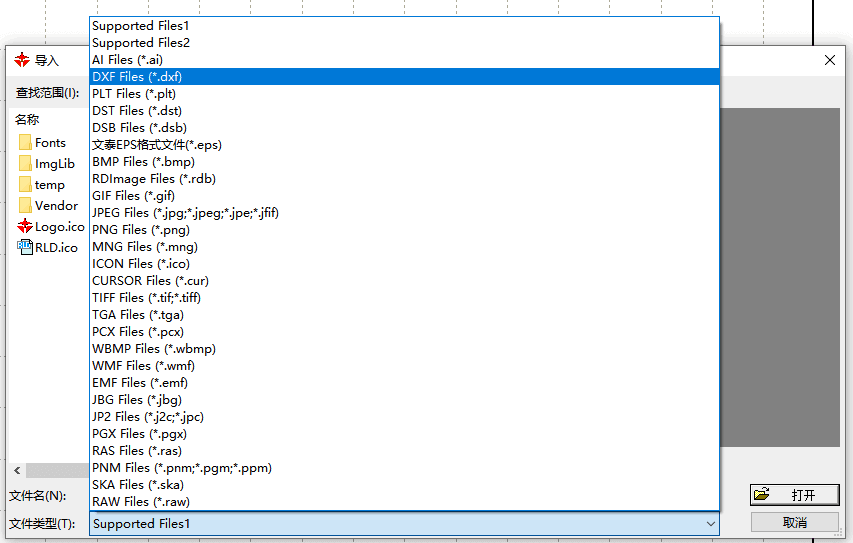

1. AutoCAD file can’t direct use to plasma cutting machine, drawing from Auto CAD can input Fastcam, plasma cutting machine can identify file which output from Fastcam.

2. Dxf, dwg, exb is common save format of AutoCAD.

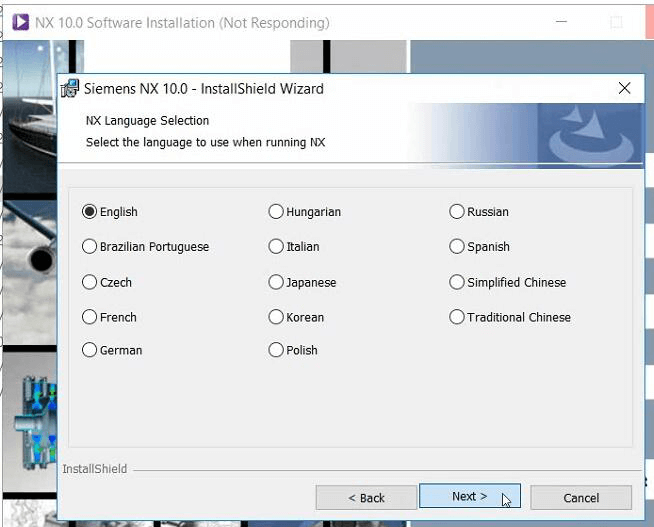

1. Full name:Unigraphics NX, from Siemens, best use prt format 3D model, ”prt” format type file saved in UG

2. Support language

English, Brazilian Portuguese, Czech, French, German, Serbian, Japanese, Japanese, Korean, Polish, Russian, Variable, Simplified Chinese, Traditional Chinese

3. We can support UG 11 and UG 10.

4. We can support 6, 8, 10, 11, 12 version.

5. Stl, igs, step format is recommended to use powermill.

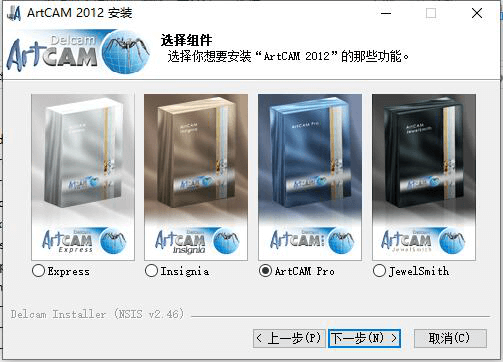

1. Support Windows, XP system.

2. Artcam have four version:Express/Insignia/ArtCAM Pro/JewelSmith

3. Support language:

Cesky/Chinese (Simplifiled) /Chinese (Traditional) /Deutsch/English/Español (Spanish) /French/Intaliano/Japanese/Korea/Polski/Português (Portuguese-Brazil) /Russian/Suomi (Finnsh) /Turkish

4. Not support Arabic.

5. After install Artcam software, alarm always appears when opening, click yes or no both ok. Because after Autodesk company acquisition Artcam, close the after-sales for artcam, so always appear alarm.

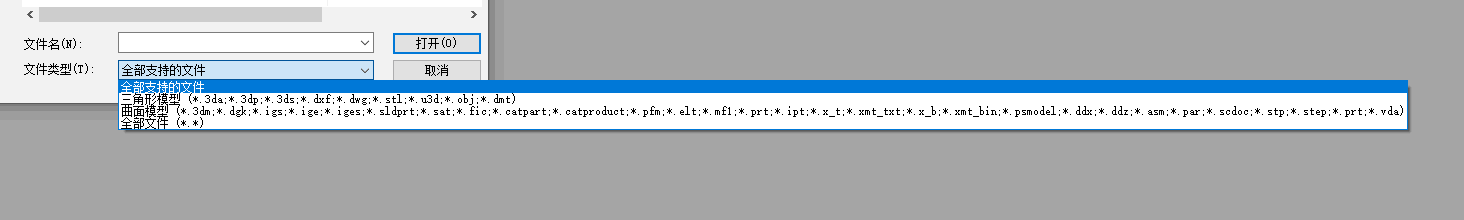

Triangle mode:3da、3dp、3ds、dxf、dwg、stl、u3d、obj、dmt

Curved model:3dm、dgk、igs、ige、iges、sldprt、sat、fic、catpart、catproduct、pfm、elt、mfl、prt、ipt、x_t、xmt_txt、x_b、xmt_bin、psmodel、ddx、ddz、asm、par、scdoc、stp、step、prt、vda

6. Artcam support two-dimensional format:dxf, dwg

Artcam support Solidworks format as follows,

Two-dimensional:dxf, dwg

Three-dimensional:igs/ stl / stp / step / sldprt / vda / ai / prt / sat

Commonly use:igs / stl / stp / step

1. Belong to Autodesk company.

2. Support language:English, French, Czech, German, Croatian, usually, Japanese, Korean, Polish, sequential, Russian, sequential, simplified and traditional Chinese

3. Powermill have 2020 version.

1. Fusion360 support real four axis ATC, we don’t have proper post processor.

2. Belong to Autodesk company, compatible with our 3 axis machine (three axis:just have XYZ three axis) , syntec 3 axis can normal use, if is 3 axis ATC need change it slightly.

1. We can support crack version.

2. Vectric Aspire not support real four axis, support rotary device.

3. Aspire support syntec control system ATC+rotary.

4. “Aspire pro”version have rotary function, ”Aspire pro”have rotary post processor. Ours Aspire is standard edition, not have rotary function, also not have post processor for rotary. Aspire standard don’t have rotary function, even have rotary post processor.

5. Version:9. 015

1. Belong to Vectric company.

2. Vcarve have two version, one is ST, another is Pro.

3. Vcarve pro version support rotary.

1. RhinoCAM can be used on real four axis.

1. Not support crack version and post processor.

1. Solidcam can make G code (program) .

1. can be used on our cnc router.

1. Machining program is G code, G code is general designation. Program include G code and M code. M code is relatively little, so we usually called G code.

2. Our machine use ISO Standard code, not special code, is Universal code.

3. G code is related X Y Z move of machine.

1. At present, cabinet design and typesetting software (cnc nest typeset) is Chinese language, need to pay.

2. Whatever is one spindle with three axis, we can think this machine is a normal three axis machine (only have X Y Z axis) , Artcam and Mastercam can be use.

3. The stage of cnc router start develop, don’t have same standard, so different brand factory’s control system have different G code format, Post processor function is change something need machining to code let machine understand----G code/machining program, so different brand control system (Siemens, syntec, etc) need post processor corresponding to generate machining program corresponding.

Our machine can use Estlcam theoretically, but the current technology cannot overcome.

https://www. estlcam. de/

1. support language

1. One software can specially for CAD and CAM, not free.

A special software have CAM and CAD function, need pay for.

2. Ucancam support language:Chinese, English, Spanish, Polish, Swedish

1. 3D design software, can create “dxf”, “dwg”picture.

1. The way for transmission:1) CF card;2) U disk;3) Internet (wire and wireless) ;4) RS 232;5) RS 458

2. Now our all control system both can use U disk to transmission file. Normally more advanced features are more comprehensive. We can follow this guide to reason that other systems we haven't touched have the same function.

http://www. richnc. com. cn

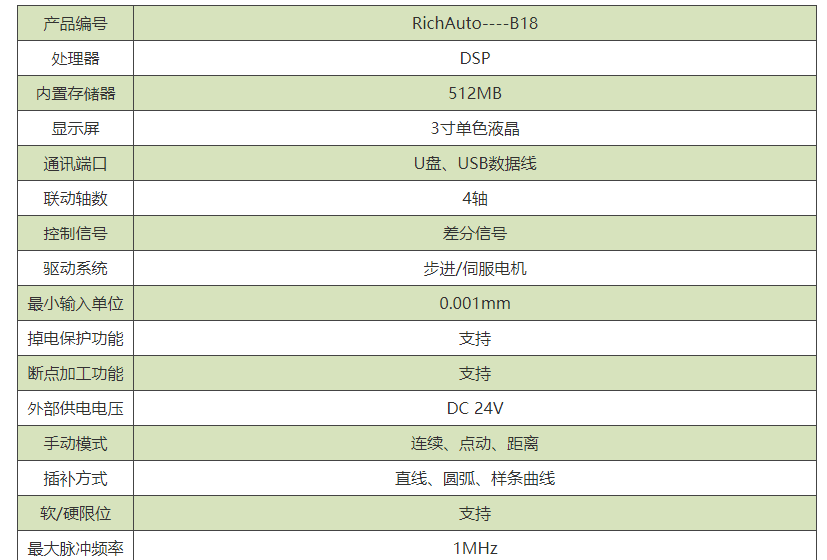

1. B18 and A 18 hand

le can common use, need change about 8 parameters.

2. DSP just release 7X control card. use computer control, connect by Ethernet.

3. DSP release F1X handle, kind of like Weihong NK105, can custom made language, also can connect computer though Ethernet.

4.  A11E

A11E A11S

A11S

In order to convenient for our customers, we usually choose A11E handle. If some customer keep a A11S handle told us this is from Blue elephant, we can make sure it is not belong our blue elephant, handle have a serial number, we can find which one from which company , like handle from our blue elephant, provide serials number to factory, factory will display”Blue elephant Mechanical Co. , Ltd.

5. DSP handle show nothing.

If this methods can’t solve, hand need return to factory.

https://www. china-cnczone. com/how-to-upgrade-dsp-a11-control-system/

6. If display tool path:DSP A5X and DSP B5X can display tool path;NK105 DSPA1X B1X not display tool path.

1. The DSP system unit only accepts mm. The customer design software can use English units. It is sufficient to produce mm when the processing program is produced. A relatively high-configuration system like the new generation of Siemens can directly change the unit of the machine to an English unit

2. Can support warning light.

3. 4 axis with moveable rotary, plug of rotary can make a independent 3 axis, can common use.

4. We can think DSP handle as a U disk, we can copy file to handle, also can output file from handle.

5. Question:Can we fix if DSP B18 handle connection position loose?

Answer:If is handle side, we can tight the screw. If still not available, we can change two connectors position from handle and control card, change handle connector position to control card position.

6. DSP don’t need USB line.

DSP have a 2. 5meter, 4meter, 6 meter wire, 6 meter longest.

7. DSP A11 RAM 512MB.

8. B18 is four axes and four linkages.

1. official website https://www. machsupport. com/software/mach3/

2. AutoDesk Mach3Mill download link: https://cam. autodesk. com/hsmposts?_ga=2. 148965685. 2061918116. 1546518503-2018726694. 1533724494

3. Domestic control card supplier official website: http://www. cdxhctech. com/ mach3

1. Not support Mac/Linus system, system must is Windows32/64bits.

2. Computer can laptop and desktop.

1. Genuine and pirate no difference, we can seek our language file from Mach3 website, import parameter.

1. We not support four-axis motion controller, can provide Mach3 control card, support rotary device, have four axis version.

2. Mach3 USB wire 1. 5 meter longest.

1. We can support with USB port.

http://www. weihong. com. cn/

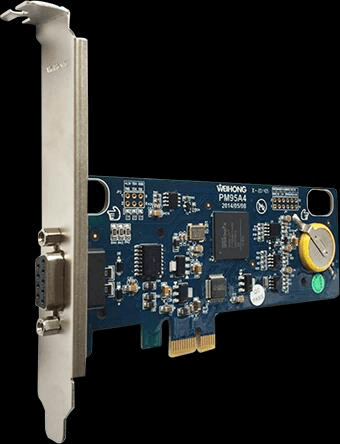

1. Not support Mac/Linus.

2. Board System PM95 Series, 53C, required computer system is Windows XP or Windows7/8/8. 1/10-32bits (only support 32 bits) , otherwise, the driver can’t be installed.

3. PS:Weihong control system support 95A-CCD, Weihong have a type system with CCD function, with camera, system can be engraved in three axes, patrol, cutout.

1. NK105 G3, support three-operation cnc router middle spindle Horizontal installation, Our Nk105 G2 handle for normal 3 axis.

2. Nk105 G3 support ATC.

3. NK105 can not be customized into French, ordinary Latin can be customized, but languages with small symbols and small phonetic symbols cannot.

4. NK105 can made normal 3 axis, 3 axis linear tool magazine ATC, three operation cnc router. Before have NK 105 handle for four axis, discontinued now.

5. Nk 105 don’t need USB wire, NK105 standard 2. 5m.

6. Knowledge of NK105 control system:NK105 G2 not support ATC. Board programming is different between G2 and G3, can’t universal. NK105 G3 support ATC, also support normal 3 axis. This two G3 control card also have different board programming. Later when you send Nk105 control card to customers, please figure out which of these three control card. if you can not make sure, please ask after-service group.

1. V5 is small Weihong 5. 515 (piracy Weihong) only support 3 axis.

2. V8 is 95A-3L, Genuine 53C (discontinued)

V8 usually is 3 axis, 95A series is 95A-3L (not support hand wheel) ;Pm95A-3A (support hand wheel)

3. 95A-4A is V10, V10 usually is 4 axis, support rotary or real four axis.

4. Weihong 95A series can support wireless hand wheel. except 95A-3L, others can support wireless hand wheel, like 95A-3S, 95A-3A, 95A-4A.

5. PM53C is cooperation with Shenyang Lathe and discontinued.

Weihong genuine control card only have PM95A series.

1. Password of control system:NK105:33587750

2. small weihong, Genuine weihong. PM95Aserious:ncstudio

3. NK260 : FYRQ

1. Weihong can add CCD, just have function for scan mark points.

2. We use a new generation of embedded CCD. At this stage, the role of the CCD is only to correct the offset of the workpiece, and it cannot generate a contour path.

1. Both can use for our office computer, only use 32 bits system, Not choose 64 bits.

2. control card:

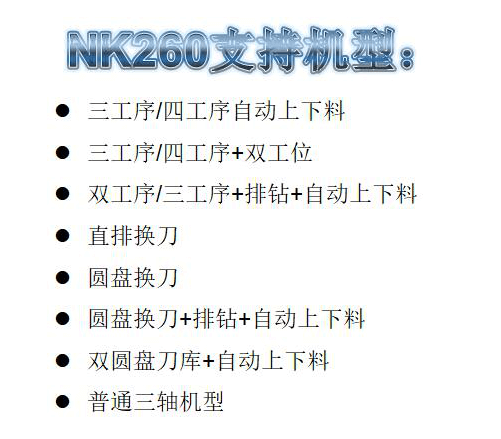

1. Support machine type

1. NK280support machine type:

手轮线长度, 正常是3米, 再长是10米.

http://www. syntecclub. com. tw:9999/download. aspx

1. Syntec can add CCD, only have function for scan mark points.

1. Can connect Ethernet, just can transfer program, can’t remote control.

2. Syntec 6Mb linear tool magazine can add 13 drill row, also can add rotary.

3. Syntec 6MB, system can hold 60 tools largest.

4. ATC can add drill row, not make if can add rotary.

5. Syntec 6MB RAM 4GB.

6. Not support sometimes remote VNC control. Support computer remote, remote by computer have a little complex, Syntec engineer try to success, have a complex process.

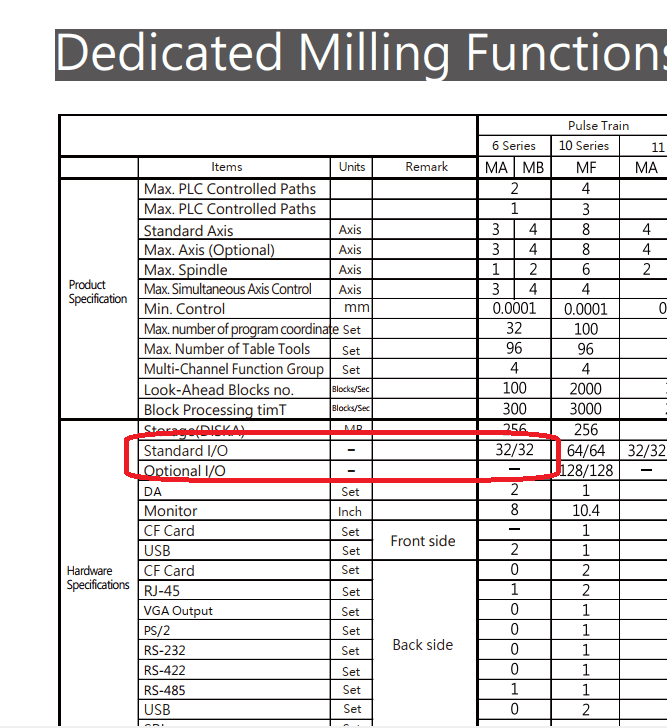

7. Input output point:6MB have 32 input point and 32 output point.

Normal ATC 4 axis can use:use 8 O point, 8 empty;use 13 i point, 3 empty.

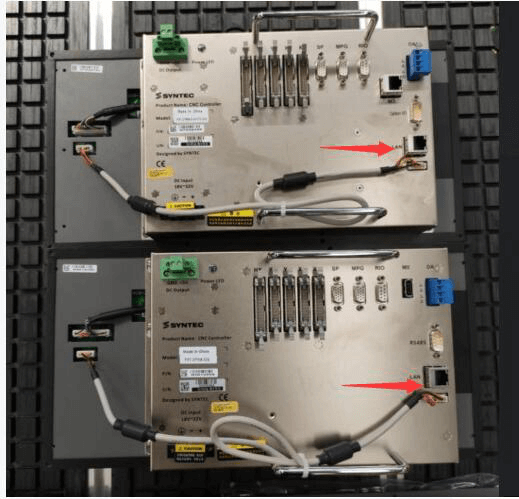

8. 6MB control panel port to connect network cable:

1. Syntec control system RAM:256MB.

2. Syntec control system password:520

3. About words of file rename:sysntec have 32 character limit.

4. All syntec system not suggest use wireless hand wheel, not stable.

Please download to “Professional technical exchange group”

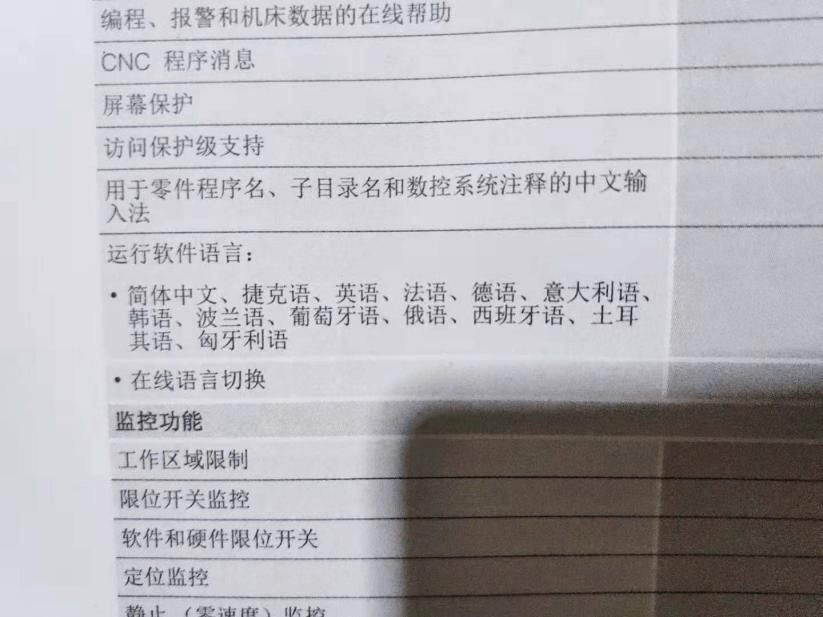

Simplified Chinese, Traditional Chinese, English.

We can add other language, need translate by ourselves, have limit on the number of words. Because the screen size is limited, the characters cannot be too much.

1. http://www.industry.siemens.com.cn

2. https://www.industry.siemens.com.cn/automation/cn/zh/automation-systems/cnc-systems/sinumerik-control/Pages/Default. aspx

1. All system support WiFi.

2. Support language:Simplified Chinese, Czech, English, French, German, Italian, Korean, Polish, Portuguese, Russian, Spanish, Turkish, Hungarian

1. http://www. advantech-lnc. com/zh-cn/

2. https://www. lnc. com. tw/zh-cn/

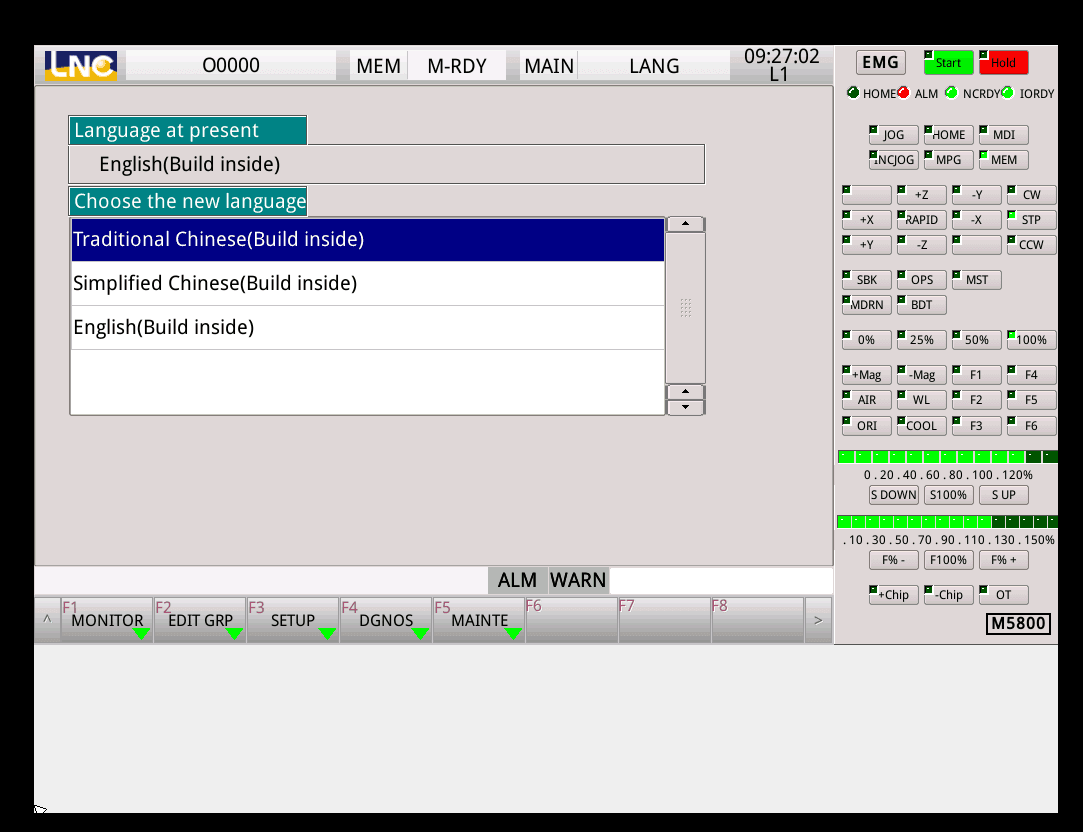

Simplified Chinese, Traditional Chinese, English.

1. Simplified Chinese, Traditional Chinese, English.

We can add other language, need translate by ourselves, have limit on the number of words. Because the screen size is limited, the characters cannot be too much.

2. Siemens 808 can only use two languages at the same time. Now that the system has Chinese and English, the third language must be installed to reduce Chinese or English. Manufacturers are not willing to give all language packages.

1. LNC 2200A transfer file by USB.

2. LNC 5800support ATC, Oscillation knife and rotary, up to 6 axis.

3. We can transfer file by network cable.

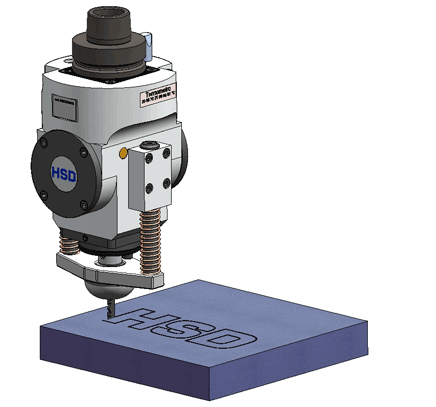

1. Customer want ATC+Right angle head to made 3D design, we recommend use Powermill or UG software, need buy post processor.

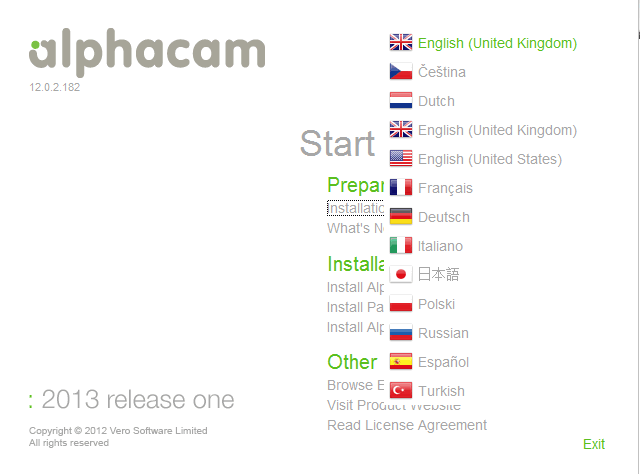

2. ATC machine, support Alphacam, need seek one post processor for syntec.

3. Our ATC machine, If have 8 tool position, customer need measure tool length once. But if tool one of eight is broke (it’s tool for cutting, not tool handle) , Siemens need measure this tool again, syntec need measure this tool and T1, if broke tool is T1, we need measure all tool length again.

4. Questions:Which compressor suitable for Linear tool magazine ATC 1530?

Answer:At least 4KW, maximum pressure of pressure tank is 0. 8 or above.

Weihong pm95a-4a

Machining without workpiece max speed is 50m/min, recommend 30m/min;machining max speed is 25m/min, recommend 10-15m/min.

Machining speed is depends on vacuum adsorption strength, tool size, shape, quality and spindle speed, etc, so this value not stable.

1. 7. 5KW HQD water cooling tool change spindle max spindle speed is 12000r/min, BT40.

2. 5. 5KW Changshen water cooling tool change spindle max spindle speed is 18000r/min.

3. Use and detection of water chiller and water pump: (recommend use high power water cooling spindle with water chiller)

Detection of water pump:put water pump in water after finished plug connector. Power on check is pump squirting water (Please note is squirting, not flow slowly) , squirting water is no problem. Then connect pipe, if water not flow, please check is spindle stuck, use pressure air to blow spindle:spindle unobstructed, need dredge spindle. water pump is to protect spindle, so whatever is or not spindle problem, both suggest customer check spindle with use pressure air.

4. 3. 5KW Xuchang ATC water cooling spindle spindle speed, can made 24000rpm, 30000 also.

1. Question:3. 5KW domestic air cooling spindle, what speed to cut 3mm thickness aluminum plate?

Answer:use cut aluminum tool, 3m/min.

1. Question:Use Styrofoam cut 1m thickness foam, How much we need Z axis height?

Answer:At least 2m.

4. Normal 1212, 6090 machine, Z height:square rail about 130mm, round rail about 140mm. If you don't raise it, , bot can not reach 160mm, this is actual data.

1. Four-axis linkage is depend on if system can support:At present all control system which support 3 axis and rotary both can support four-axis linkage.

1. The A axis is rotated around the x axis, the B axis is rotated around the y, and the C axis is rotated around the z.

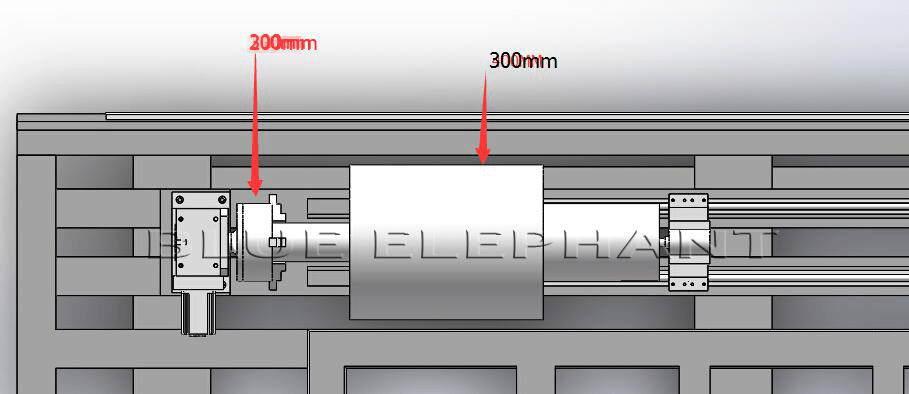

2. Question:Only rotary machine, 200 chuck, whether can machining a stuff with 300 diameter?

We need make sure the position of the chuck is not more than 200. Only rotary machine don’t need customized machine lathe, it is not available if rotary is in machine table side, or independent rotary, maybe will hit the rail.

3. Question:What is the minimum diameter of work piece when use 100 diameter chuck rotary?

Answer:If work piece is a little hard, about 10 mm, but length will limit.

Please realize https://zhuanlan.zhihu.com/p/53869261

1. Tool manual http://www.zuojiaju.com/thread-655008-1-1.html

http://www. zuojiaju. com/thread-46948-1-2. html

2. Have 45 degree aluminum tool, other degree need customized.

3. 6mm is we said machining position diameter (Blades diameter) , it is what diameter of tool.

4. Our one carousel tool magazine maximum can put 20 tools. If customer need Linear tool magazine we can made two rows, need lengthen, . X=1300mm, linear tool magazine maximum put 9 tools, two rows can put 18 tools. X=1600mm, linear tool magazine can put 12 tools, two rows can put 24 tools. X=2000/2100, maximum put 16 tools, two rows can put 32 tools.

5. Machining this V-groove

Tool for machining V-groove

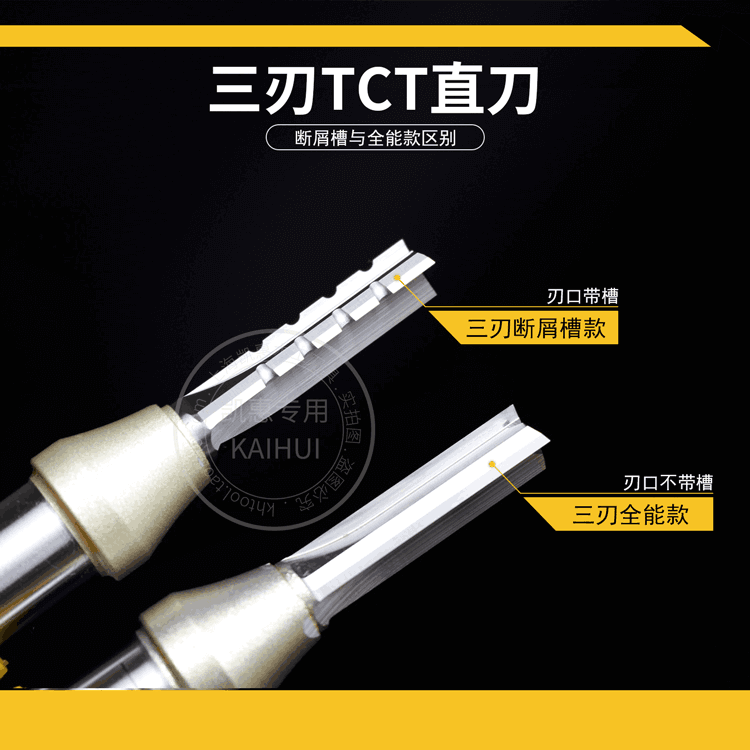

6. Three-edged straight flute knife

7. Customer machine is 9KWATC spindle, ISO 30 tool holder, How much weight can the heaviest for tool?

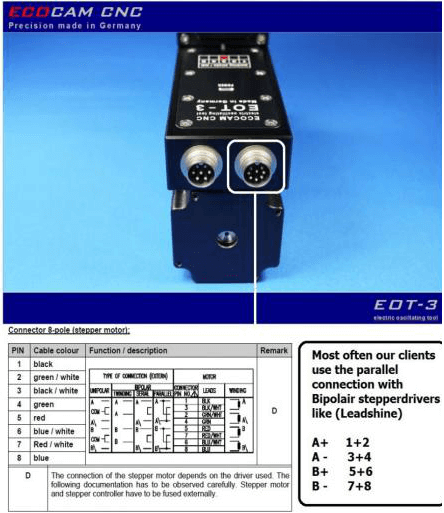

1. EOT-3 is electric Oscillation knife, not for pneumatic.

1) Pneumatic oscillation knife (punching tool)

2) Domestic electric

2. EOT-3

3. Oscillation knife

http://www. bagcad. com/usercategory/product/100598/

4. The pressure wheel can also be added with the oscillation

knife

5. Control system of Germany oscillation knife and pressure wheel (without spindle) can use Ruida.

6. Siemens not support Oscillation knife.

7. Our 1625 oscillation knife can cut soft PVC Maximum thickness≤16mm

8. EOT can cut minimum circle of 10mm diameter.

9. Does our oscillation knife can cut wool felt?

It is theoretically possible, but it needs to be tested. It is better to let the customer send a piece of material.

10. Question:Our customer wanna add this right angle head, cut maximum 130mm foam, Does this right angle head same as oscillation knife, buy different length tool?Please help to make sure what max thickness can cut?

Answer:Max tool length can cut 120mm, need customized tool, it not doesn’t matter of right angle head, need customized tool.

1. HQD 4. 5KW air cooling tool collect is ER32, max can hold 20mm diameter tool, manual said is ER25.

2. What max hold tool diameter of ER11?8mm

1. 6090 can add 750W leadshine hybrid Servo, add 30mm in length and width.

1. Official website introduction, http://www. leadshine. com/productdetail. aspx?type=products&category=servo-products&producttype=brushless-servo-drives&series=ELD5&model=ELD5-400

1. Machining without workpiece speed is 40-45m/min

1. Question:Does motor will influences machine accuracy?

Answer:Normal is result of all component cooperate working, like gear and rack, gear and motor shaft, react ability of control system. Compared to these effects, the effect of the motor is very small and can be ignored.

2. Our stepper motor don’t have power, have torque, torque constant. Much more speed, need more power

3. Three operation cnc router with middle horizontal spindle suggest use servo motor.

4. Both is brushless Motor.

5. What the max speed of 850W leadshine pure servo?

If we ignore the stroke , reach the maximum speed of the motor, can reach 100m / min.

6. Delta Servo Torque 3. 2nm

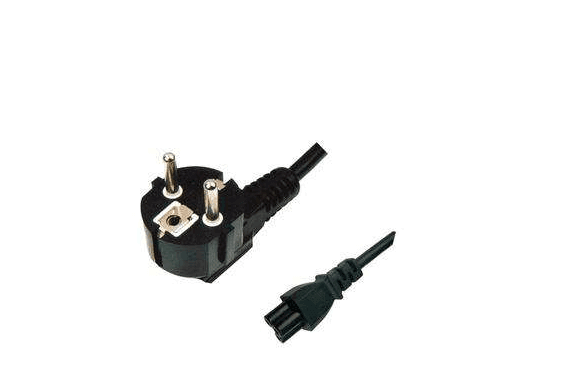

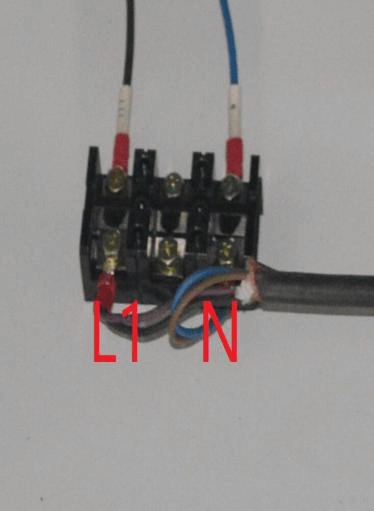

1. Power cable about 1212 and 6090 ball screw cnc router. send customer with maching usually is Europe standard, please ask if have some special requires.

2. 7. 5m wire for 1530 plasma cutting machine is enough. working table is 1530 or over 1530 area need use 15m wire.

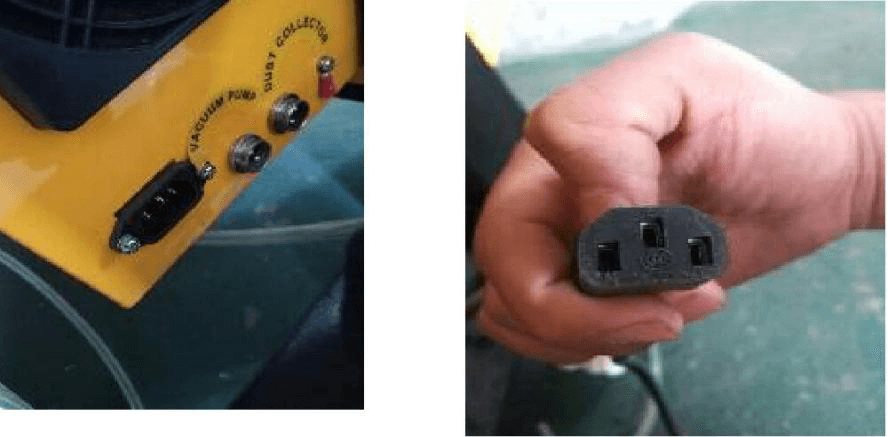

3. Customer need extra buy cable which connect water vacuum pump.

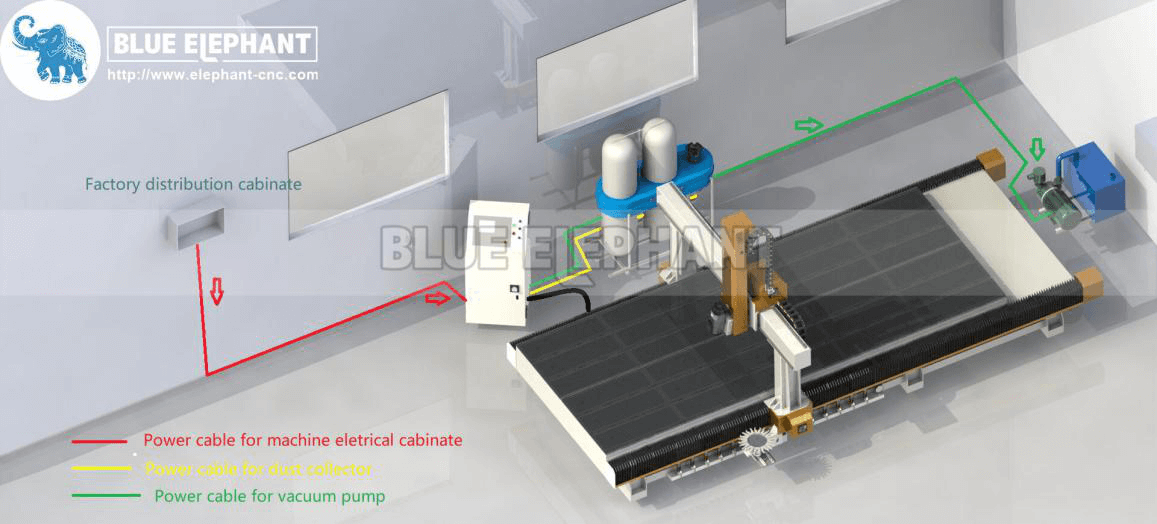

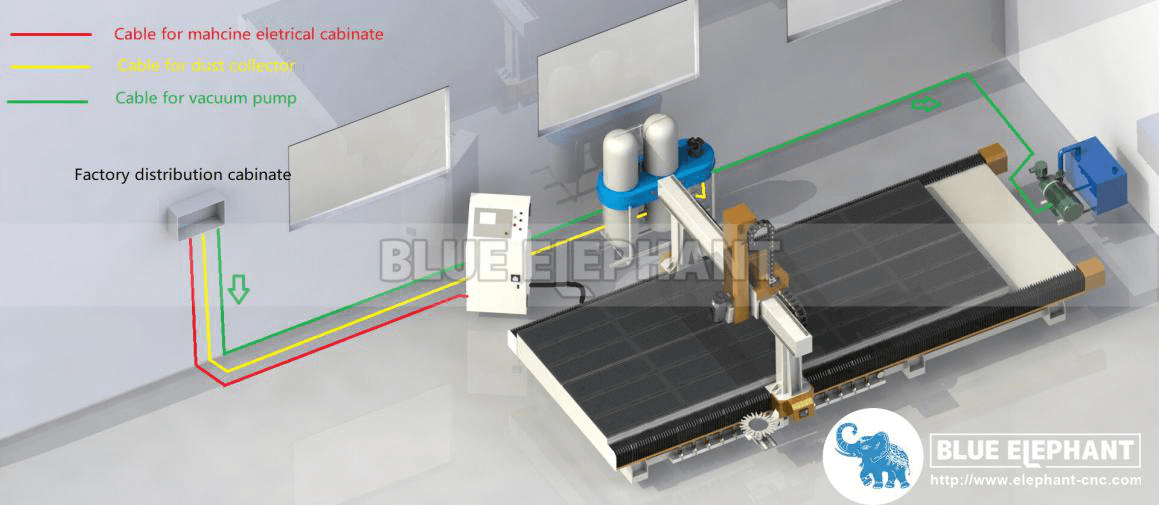

Only 1212 6090 ball screw cnc router with this power cable. Other machine without power cable if not write in production order, because we don’t know how much site area of customers.

This type without power cable.

This type with power cable.

1. The general national supply standard is 10% floating up and down, but large factories like shell pumps are 5% floating

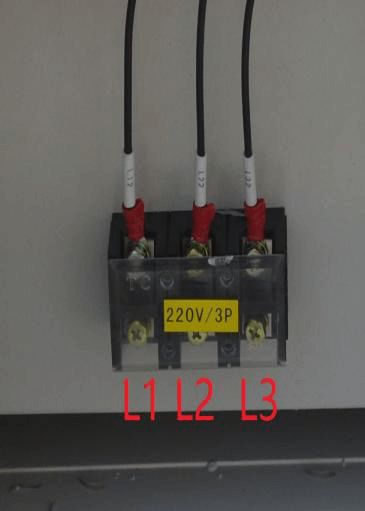

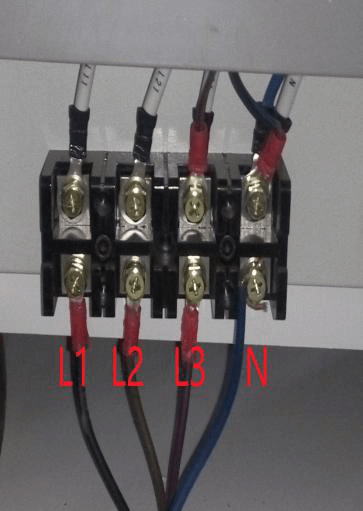

1. Machine voltage is 380V, dust collector voltage is 220V, can use together. There are 3 ph of 380 electricity, absolutely have 220 1ph of electricity. If it is a 3ph 220 V vacuum pump, we must add a transformer.

2. Calculate motor current Power:

http://tool. 520101. com/dianlu/dianjidianliugonglv/

3. (3000*3+2200*2+1500) /220≈68A

Questions:customer voltage is 220V, 1ph, 60Hz, 1325 one spindle with 3 axis cnc router, 3KW water cooling spindle, 2*2. 2KW vortex pump+1. 5 dust collector. How much amps we need?

Answer: (3000*3+2200*2+1500) /220≈68A

4. Calculate Power

Spindle +motor+dust collector+vacuum pump, we calculate which component waste power, suggest use independent power for vacuum pump

1. About 3 axis machine with syntec controller, normal 3 axis with multi-operation cnc router, not suggest use simple auto tool sensor.

Reason: 1) complex operate, we need press many button to finish. 2) Only use auto tool sensor , will limit process speed when measure tool length, slowly speed, only for Z axis, XY need set manual. 3) Like syntec normal 3 axis or ATC machine, manual set workpiece zero point is the most fast way. We suggest that not add simple auto tool sensor for syntec without ATC machine and Siemens machine. 4) Even if machine have ATC, auto tool sensor function only have measure tool length, . workpiece zero point also need set manual.

2. Ours calibration use to measure tool length.

1. A11s (Simplified Chinese) , button is Chinese and English.

A11E (English) , button is English.

2. Wireless handle need add battery.

Chuck divide into three-jaw self-centering chuck, four-jaw self-centering chuck and ordinary four-jaw chuck. At present, we use self-centering chuck, also called three-axis linkage, four-axis linkage chuck.

The detailed classification of the reducer, please go to the technical exchange group to download it.

450B motor speed reduction ratio of common rotating shaft: 20: 1

1. The front integrated cabinet is generally used on the square tube machine, and the built-in cabinet is generally used on frame machine

2. Try not to do vacuum table if it is built-in cabinet.

3. Normal 3 axis machine with stepper motor, it is enough to use one side cabinet.

Use servo motor, like three operation cnc router, because have many small component, so at least use double-side cabinet.

1. Machine with pressure roller don’t need pressure plate to stable materials.

2. Pressure roller belong to non-standard parts, need customize, delivery time is about 20 days.

Called water chiller, cooling for torch.

1. Drill row only can make hole, can not cutting, drill row little thin, can move landscape or portrait,

Right angle head is cut in two direction.

1. PSI English full name is Pounds per square inch. P is pound;S is square;I is inches. It can be calculated by replacing all units with metric units: 0. 1MPa=1bar≈14. 5psi

2. We usually use it on air compressors to indicate air pressure.

1. New type double bag dust collector:suction 3540m³/h

2. 1. 5KW New type dust collector220V/380V:5. 76A/3. 33A

1. Dust pipe diameter 100mm

2. Main parameter of dust collector is air volume and air speed

3. Our 1. 5KW new type dust collector and old type dust collector is working after connect power, not have adjust switch to spins.

1. Pipe which connect air compressor diameter is about 8mm, can use adapter connect 12mm diameter pipe.

The air compressor is piston type.

1. blade, grease, oil sil

2. Dry vane claw pump

Dry vane claw pump

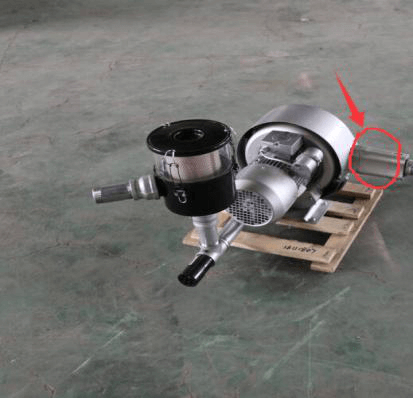

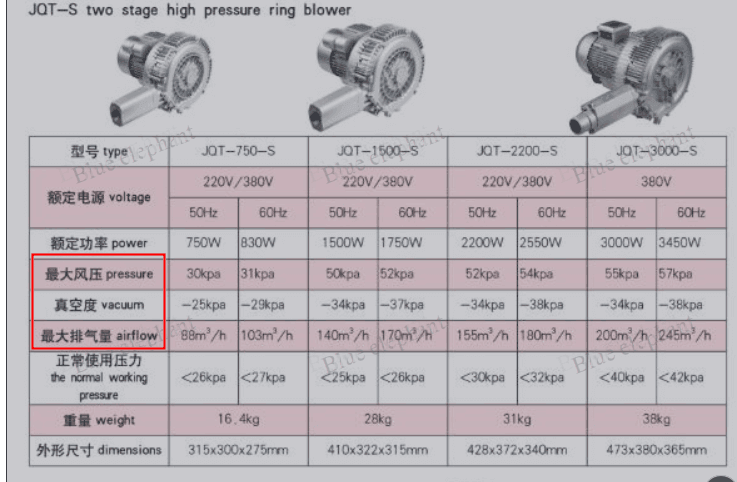

1. 2. 2KW JQT vacuum pump:10A

2. Vortex pump use after a period of time will be hot:it is normal heat up after power on, air be compress internal energy increases exothermic. In a good ventilate, surface of vacuum pump will reach balance point in 80℃, temperature doesn’t fluctuate greatly.

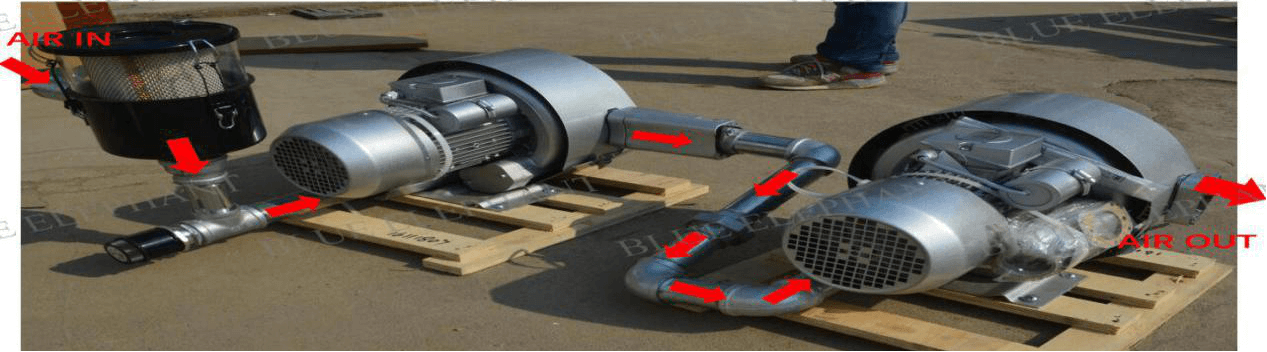

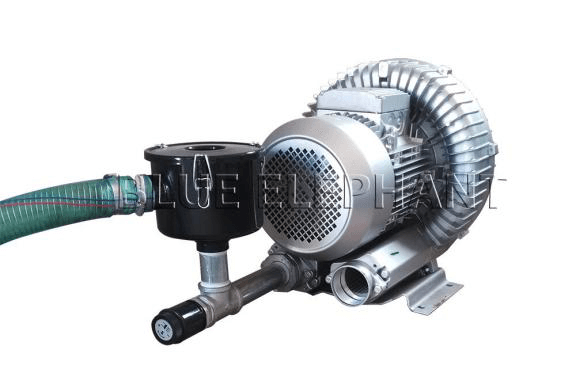

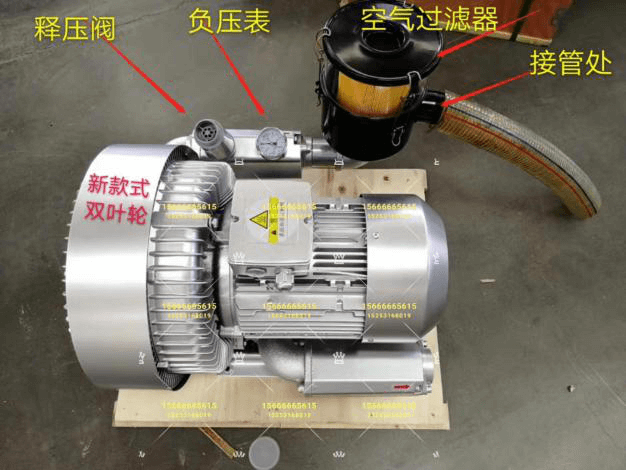

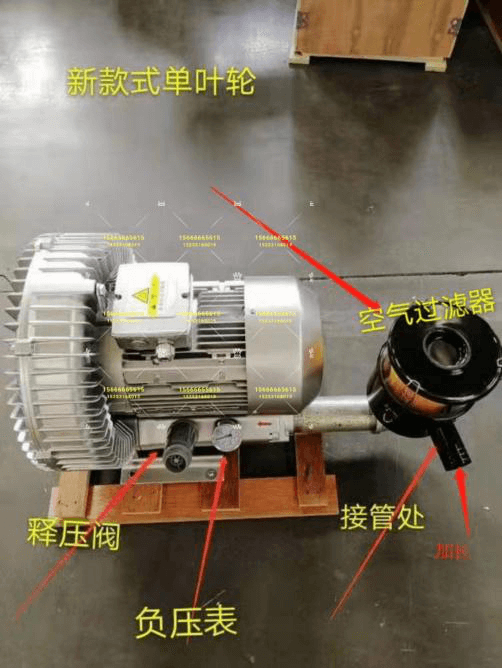

1. JQT双段旋涡泵, 有单台的也有双台的

2. 旋涡泵带过滤器, 旋涡泵的原理其实就是抽气的鼓风机 风冷的

(need install)

(need install)

1. After vacuum pump work finish, if pipe which connect machine is negative pressure, it’s pipe pressure less than vacuum pump. When you stop the vacuum pump, water will flow to low pressure side.

2. Water level:can exceed the maximum water level a little

3. Why water boiling:motor working will heat up, heat dissipation is not as fast as heating, lead to water boiling, it is normal.

4. We can add a cooler inside to cool down and change the water frequently.

5. 3KW water pump size:770*700*680

2. 2KW double segment vortex pump size:400*420*460

6. Water level keep near the High water level, water effect:sealed and cooled.

You will find many steams output If water pump open a long time

1. Our 7. 5KW air compressor, maximum pressure is 1. 2mpa, gas tank volume us 180L (0. 18m³)

Main valve connect two type hose, suction port is white on working table, almost is 40 diameter hole, little is 50 diameter, green suction port is 32 diameter hole, vacuum valve general is 40 diameter hole.

1. Capacity is 4L.

1. Teyu water chiller official website:http://www. teyu. com. cn/lengshuiji. shtml. The two white transparent tubes inside the energy chain are for cooling the water-cooled main shaft, they and are connected to water-cooling devices such as water pumps or water coolers.

2. Spindle cooling type is water cooling need add a water chiller.

3. Standard voltage of water chiller is 220V 1ph, customers can connect chiller to family power.

4. CW5000 water cooler The 5000 is just a number and has no special meaning. It may be that the 3000 represents a smaller model and the 5000 represents a larger model.

Volume don’t less than 48L.

Balance cylinder:install on machine head

Load feeding cylinder:behind gantry obliquely install

Dust cylinder:install on dust cover

Location cylinder:front of machine and side

After cutting push finished stuff to loading table.

1. Because ball screw cnc router is cast iron bed, we can’t weld by ourselves, so can’t add location cylinder. Otherwise, X Y axis of ball screw cnc router is add dust cloth.

Question:Does T slot on vacuum table can be more dense?

Answer:It will affect effect, if more dense, more T-slot, vacuum area will be less.

Parameters that need to pay attention to limit purchase:normally closed switch, DC 24V.

1. Rubber strip: 1) Laying should be smooth, not undulating; 2) After the rubber strip is finished, the surface should be higher than the countertop area.

2. Try to follow how big the material is and how big the area is. If you don’t need it, close it in time to avoid inhaling excess gas.

3. Listen:Listen if have some sounds like leak air bottom of machine.

4. Water temperature:excessive water temperature will affect some adsorption effects, it is recommended to recycle the water.

5. Work table:Please keep work table clean. Debris will also affect the adsorption effect.

40%~60%

Machine working in -10℃ is no problem, we suggest that machining after use low speed warm up, our machine can working in -10~45℃.

First step:rough home, machine find limit sensor first.

Second step:accurately home, will back a little after find limit sensor, then home. advantages is home accurately.

Machine both have filter, has nothing to do with the spindle. Filter function is prevent electromagnetic interference.

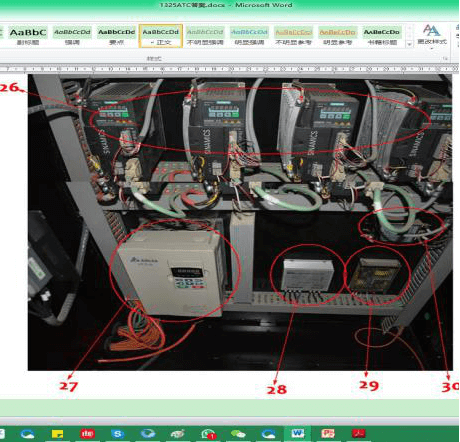

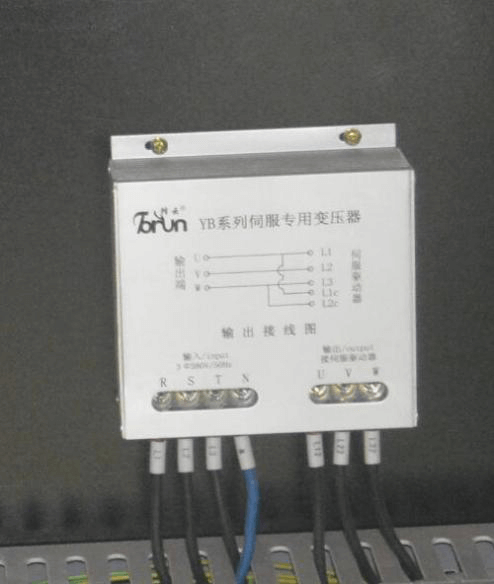

(30)

(30)

Electric from transformer though filter to filter clutter, then go to driver.

1. Good fire resistance, no flammable resin, no toxic gas, flame retardant and self-extinguishing.

2. Low loss and low noise.

3. No pollution, no maintenance

4. Economical installation, can be installed and load center, no special foundation is required. Generally used in YAKO and Leadshine control stepper driver

1. Small size and light weight.

2. Can cooling by air, no insulation oil is needed for isolation, reducing pollution, convenient maintenance and good safety.

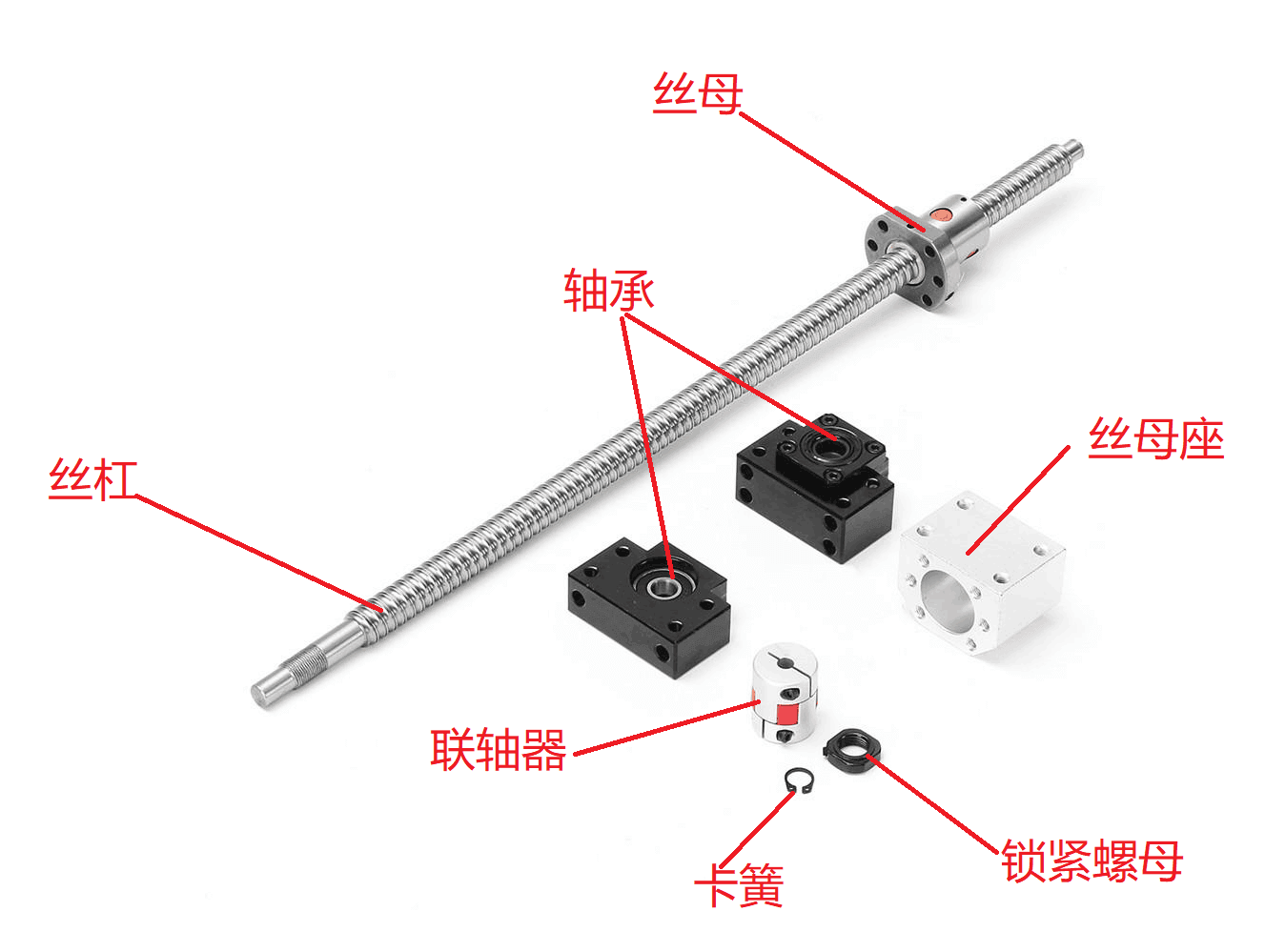

Our ball screw cnc router have coupling, XYZ 3 axis both have. 6090 ball screw cnc router Z axis is 16 diameter;XY axis is 25 diameter.

1. Cause of oil leakage

Automatic lubricating oil can have two time need set, one is how long to add oil, another is how often to add oil, add oil time is 6 seconds, after 240 minutes add oil, so lubricating will add 6 seconds oil after every 240 minutes, 6 seconds is how long add oil.

1. Side hole machine support language:Chinese and English

2. Side hole machine normal machining small size plate, plate require:less than2500*1000mm

1. Little machine (laser machine) add CCD to scan, identify same shape for cut. General used to cutting like logo shape.

2. Co2 laser machine add auto focus, need add lifting table;can’t add auto focus if not have lifting table, nothing makes sense.

3. Does Co3 laser machine can create G code?

Like Ruida control system in laser machine, create “rd” format file, it is special format for laser machine, not G code and graphics.

Ruida can read file with follow format,

1. Plasma cutting machine cutting square tube (cut or cut a gap) , need support 6 axis FL6600 control system.

2. Fang Ling can customized language.

3. Fang Ling system manual only have Chinese and English version.

4. F2600 support Chinese, English, Spanish, Portuguese, French, Russian, Danish, Korean, Japanese, except Chinese and English, we need customer support language translate software, can support language except Arabic.

1. Password, on machine manual.

1. Question:How much power supply when cutting 16mm aluminum and stainless steel? Answer:200A

2. 3mm galvanized iron plate (plasma can be cut, but it will be burn edge) requires 63A power supply

3. How much power supply we need when we cut 32mm iron?300A power supply

1. Does our flame can cut 130mm carbon steel?

Flame cutting and plasma cutting is two different way, can use a same system control (can not use two type together) . Thickness for flame cutting is between 1mm and 1200mm. Different configuration, different cutting materials range.

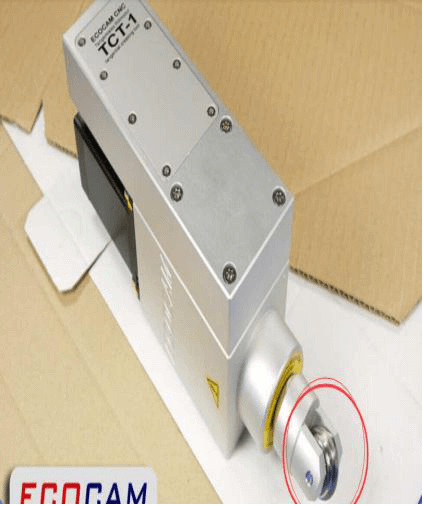

Question:Why have above pic“cutting defect”which circled by blue pen. The cutting part (inside circle) is what we want, why?

Answer:Every time when plasma cutting machine start cut, need from a point to start, cutting (make a hole) steel plate, then cutting. Circled by blue pen, we called “lead-in and lead-out line” (or:“cut-in and cut-out line”) , in order to make a hole in outside, not damage workpiece, because what we need is inside. Similarly, If sample is in outside, software will put let cut-in and cut-out line inside. It is not “cutting defect”.

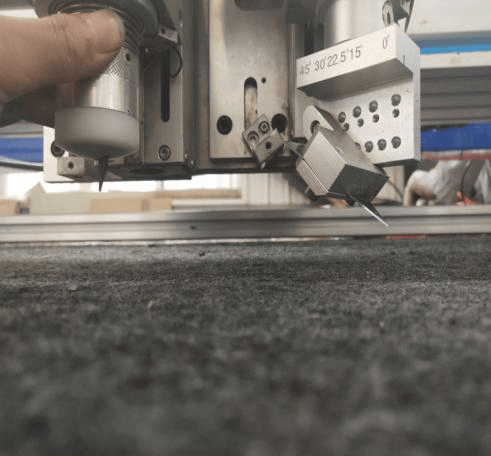

We can adjust the tool degree, tool have 4 rows of small holes, can adjust 4 degree, can be 45°, 30°, 22. 5°, 12. 25°.

1. 保利龙机器z轴可以做到1200

Styrofoam machine Z axis stroke can reach 1200mm

1. 咱们精密锯可以配吸尘器

Our precision saw can use with dust collector.

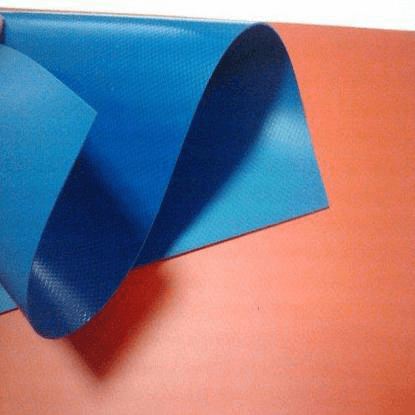

| PVC canvas |  |

crystal |  |

| plexiglass |  |

sponge |  |

| Thai sandstone |  |

Vietnan limestone |  |

| Soft silicone phone case |  |

PS:1. Soft silicone phone case can’t made by our machine, can not reach phone case accuracy, also surface effect

Methods to made soft silicone phone case:

1) Solid silicone double low temperature thermal vulcanization molding

2) Injection molding with platinum vulcanized liquid silicone

| leather |  |

rubber sole, 60mm thickness |  |

| Silica gel Silica |  |

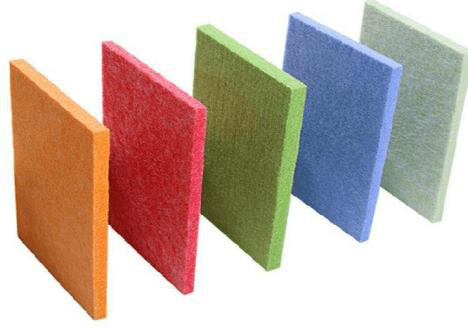

Polyester fiber sound-absorbing board |  |

1. Our machine can use to polyester fiberboard to drill. minimum diameter is 1mm.

2. PE Foam X suitable Oscillation knife.

| Medium Density Fiberboard=MDF |  |

Paint board/Baking sheet |  |

| Particleboard |  |

Oriented Strandboard=OSB) |  |

| Melamine-covered particleboard |  |

fire board |  |

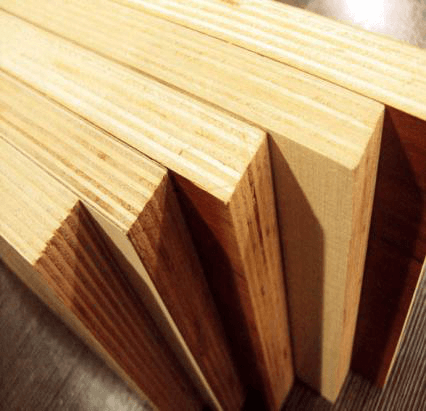

| Plywood |  |

decorative panel |  |

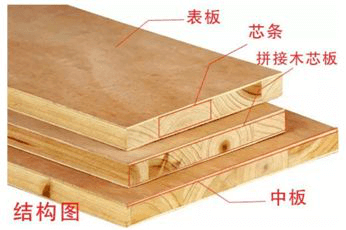

| Blockboard |  |

Finger joint wood |  |

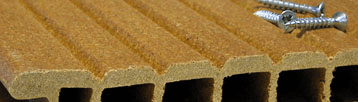

| Wood-Plastic-Composites, WPC |  |

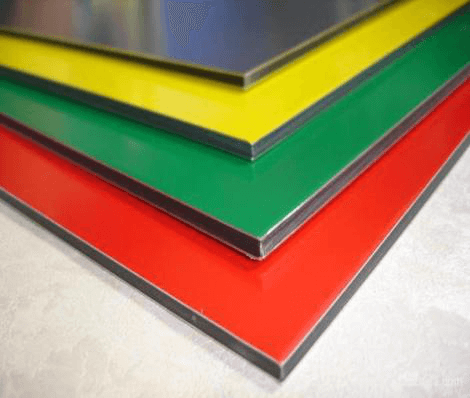

Aluminum composite panel |  |

| polypropylene (PP) |  |

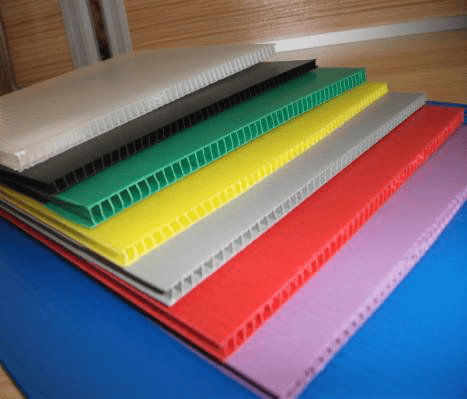

Corrugated plastic |  |

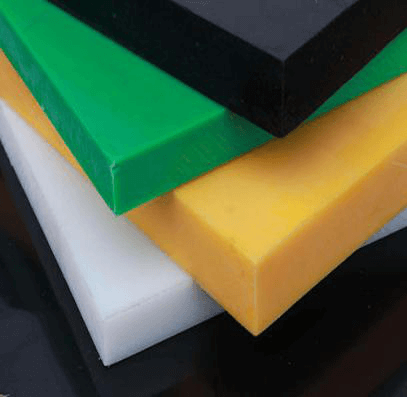

| UMHW (UPE) |  |

Polytetrafluoroethylene=PTFE |  |

| High Density Polyethylene=HDPE |  |

polyformaldehyde |  |

| aluminum gusset plate |  |

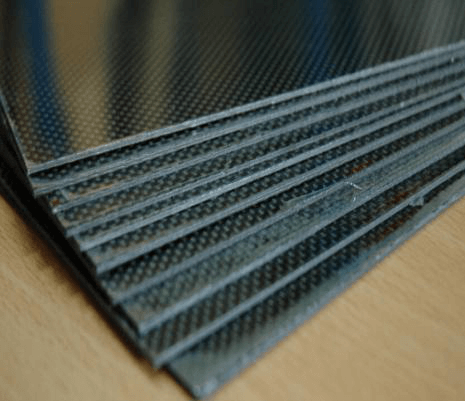

carbon fiber plate |  |

| Fiber glass board |  |

25mm melamine board (particle board) , normal 6-8m/min, one time cut with 8mm three-edged straight flute knife

18mm melamine board (particle board) , normal 10-15m/min, suggest 10m/min, the more fast speed, the more degree tool abrasion, one time cut with 8mm three-edged straight flute knife.

18mm ecological board (multi-layer board, solid wood splicing board) , normal 10-15m/min, suggest 10m/min, the more fast speed, the more degree tool abrasion. one time cut with 8mm three-edged straight flute knife.

| Aluminum shoe mold |  |

Aluminum |  |

| hard aluminum alloy |  |

| Marble |  |

bluestone |  |

| plasterboard |  |

Imitation marble (The main ingredients are: resin. Can be understood as plastic. ) |  |

1. Does our Stone cnc router can working with this jade?7mm thickness

Ok, please realize waterjet cutting machine.

1. Does stone cnc router can machining with marble and granite tombstone?

It’s no problem If don’t need polish. Our machine can’t polish, almost tombstone is splice. If only can make cut, please choose waterjet cutting machine and saw blade.

| Galvanized steel |  |

steel |

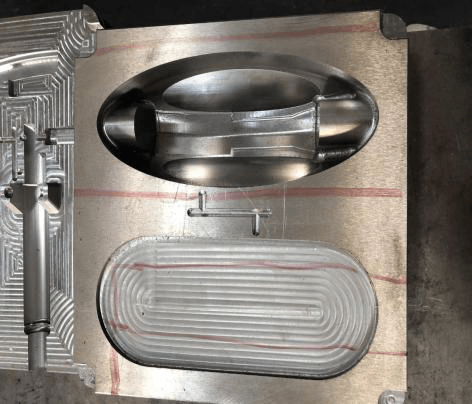

1. Bathroom supplies suitable for our machine. Normal 3 axis can do it, can rough working also fine finishing, need make the tool path fine.

2. Does our machine can cut max thickness 18mm glass?

Put a acrylic under glass, cut little by little, high time cost.

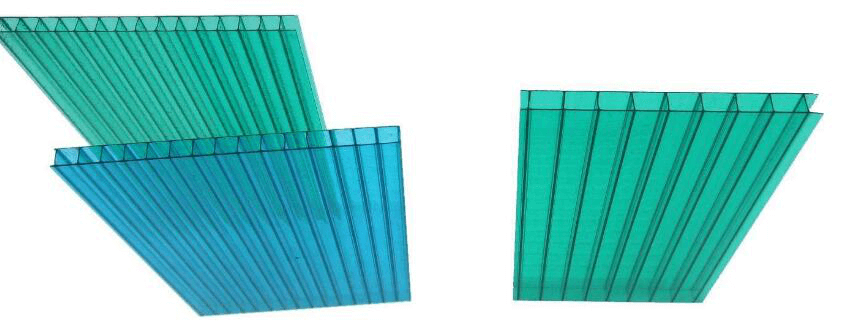

3. Our machine can cut and make hole for 6mm polycarbonate sheet.

|

|

|

|

|

|

|

|

|

|

|

|

|

We can understand torque as power. power of servo is constant. All power of motor is constant. At a low speed, more power;At a fast speed, less power.

Stepper motors are constant torque. The faster the speed, the greater the power.

1. Does our machine can working in 60℃?

No, 60℃The power of the motor and drive will drop sharply, and the electronic components cannot stand, Yaskawa motor power just reach 50% than rate power.

1. Lubricating rail main to lubricating slider, once a day to lubricating after use machine, not suggest use grease, have h5 adhesion, It is not easy to clean if dirt falls on top

2. Lubricating oil normal use 32#-68#, 5W-30 (car motor oil)