There are many kinds of cutting machines, and

fiber laser cutting machines and

CO2 laser cutting machines are the two most commonly used cutting machines. From their names, their difference is that fiber laser cutting machines use optical fibers for cutting, and CO2 laser cutting machines use CO2 for cutting. So, what are their specific working principles, what materials can they cut, what are their respective characteristics, and which of these two cutting machines is more suitable for you? Follow me to read this article, and I believe that all your problems will be solved afterwards.

What Is A Fiber Laser Cutter and What Is A CO2 Laser Cutter?

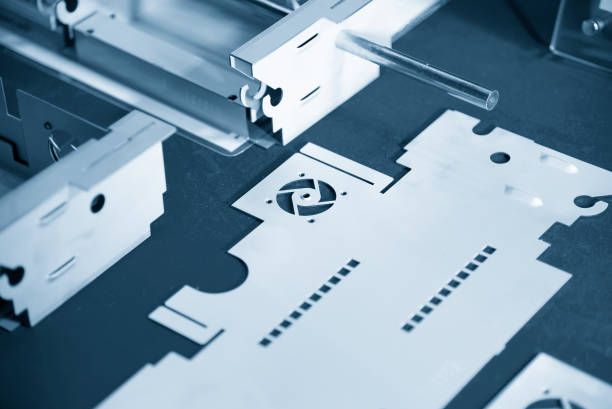

Fiber laser cutter is a machine that uses fiber laser to cut metal. It combines fiber laser with CNC machine tools and controls the laser beam through the system, making metal cutting more convenient and efficient. Fiber laser cutter is mainly used for cutting metal sheets and pipes.

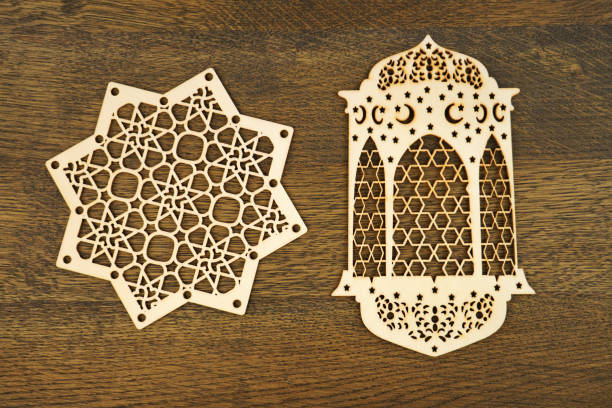

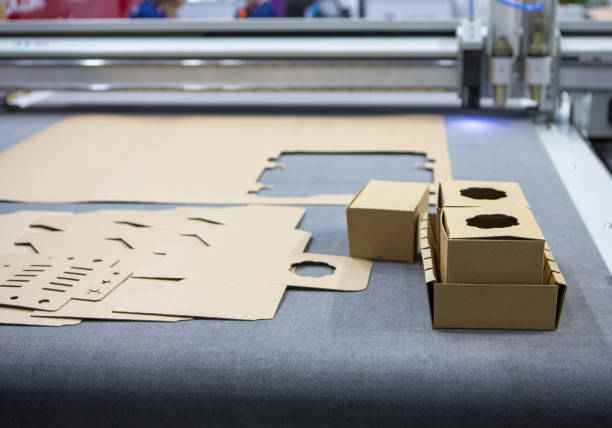

CO2 laser cutter originated in the last century. It is a cutting machine that uses carbon dioxide for laser cutting and engraving. It can be used for both cutting and engraving, so it is called a CO2 laser cutter and CO2 laser engraving machine. CO2 laser cutter is constantly upgraded with the development of technology. Compared with the metal industry, CO2 laser cutters are more suitable for non-metallic industries and have great advantages in non-metallic material processing. They are mainly used for wood processing and carbon dioxide processing. Different power lasers can be selected according to the thickness requirements of the customer's processing materials.

What Is the Working Principle of Fiber Laser Machine and CO2 Laser Machine?

The principle of fiber laser machine: the fiber laser outputs a high-energy-density laser beam and focuses it on the surface of the workpiece, causing the area on the workpiece irradiated by the ultra-fine focal spot to melt and vaporize instantly, and the irradiation position of the spot is moved by the CNC mechanical system to achieve automatic cutting. It is a high-tech equipment integrating laser technology, CNC technology, and precision mechanical technology.

The principle of CO2 laser machine: CO2 laser machine uses a focusing lens to gather CO2 to the surface of the material to melt it. At the same time, the melted material is blown away by the gas equipped by the machine. The laser beam moves along a certain path to form a slit of a certain shape. Then the cutting process is completed.

Whether it is a fiber laser machine or a CO2 laser machine, their working principle is to make the workpiece reach the melting point and melt or vaporize, so as to achieve the purpose of cutting and punching, but the materials used are different.

What Materials Can Be Processed by Fiber Laser Cutting Machines and CO2 Laser Cutting Machines?

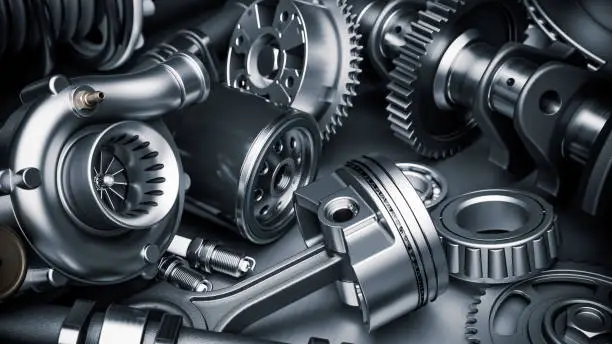

Fiber laser cutting machine can cut a variety of metal plates and pipes, mainly suitable for stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized plate, galvanized plate, pickled plate, copper, silver, gold and other metal plates and pipes. Mainly used in metal sheet processing, advertising sign production, mechanical parts, kitchen utensils, automobiles, machinery, metal crafts, saw blades, electrical parts, spring sheets, circuit boards, electric kettles, medical microelectronics, hardware, knives and measuring tools and other industries.

CO2 laser cutting machines can process both metals and non-metals. 40W CO2 laser cutting machines can engrave on steel, and 90W CO2 laser engraving machines can directly engrave steel structures. 150W and above CO2 CNC laser cutting machines can cut 1mm thick steel plates.

Generally speaking, although CO2 laser cutting machines can process metal materials, their cutting efficiency is low and far inferior to that of fiber laser cutting machines. Therefore, CO2 laser cutting machines are very suitable for cutting and engraving non-metallic materials. CO2 laser cutting machines can cut and engrave materials including: mild steel, steel, aluminum, titanium, alloys. Wood, acrylic, paper, fabric, epoxy resin, resin, plastic, rubber, crystal, leather, stone. CO2 laser cutting machines are widely used in clothing, leather, fabric toys, computer embroidery cutting, electronic appliances, models, manual technology, advertising, decoration, packaging, printing, paper products and other fields.

Advantages and Disadvantages of Fiber Laser Engraver and CO2 Laser Engraver

Fiber laser engraver is small in size, long in life, highly stable, and maintenance-free. In addition, they have superior beam quality and high photoelectric efficiency conversion, making them the main application objects in the laser processing industry. Fiber laser engraver has the following advantages:

(1) High-power fiber laser layer devices are all double-clad optical fibers. The pump light hits the outer cladding, the energy is absorbed, and then partially converted into fiber lasers. At present, various countries have developed optical fibers in various shapes, including round, D-shaped, rectangular, plum blossom, square, flat threaded, etc.

(2) Fiber laser engraver can work at very high temperatures, without the need for high-power wide-surface multi-mode diodes such as thermoelectric cooling appliances, and only requires simple air cooling, which is low in cost.

(3) Using multiple high-power LD single tubes instead of integrated arrays can improve the mode of the light source and facilitate the heat dissipation of the pump source, thereby increasing its lifespan.

(4) High precision, fast speed, smooth cutting surface without burrs;

(5) The laser cutting head does not contact the surface of the material and will not scratch the workpiece;

(6) It can perform deformation-free cutting on materials of any hardness, such as steel plates, stainless steel, aluminum alloy plates, and cemented carbide.

(7) The cutting slit is the narrowest, the heat-affected zone is the smallest, the local deformation of the workpiece is very small, and there is no mechanical deformation;

While fiber laser engravers have great cutting advantages, they also have some defects: the purchase price of fiber laser engravers is relatively high, and they are also limited to some metal cutting. They do not have an advantage in the non-metal field and are mainly processed by co2 laser engraver.

CO2 laser engraver has the advantages of fast cutting speed, high efficiency, small heat-affected zone, narrow incision, suitable for cutting non-metallic materials, no direct contact with the processing material, and no restrictions on the shape of the cutting material.

The light conversion rate of Co2 laser engraver is relatively low, and the core technology of high energy consumption is difficult to overcome. Most machines are mainly imported from Europe and the United States, so the machine is expensive. In addition, the maintenance cost of accessories and consumables is also high, making the actual use and operation cost relatively high.

Product Display of Machines

Product Display of Fiber Laser Cutting Machine

Product Display of CO2 Laser Cutting Machine

Machines Recommendation of Fiber Laser Cutter and CO2 Laser Cutter

Top Ranked Automatic Coil Fed Laser Sheet Cutting Machine for Fiber Laser Metal Cutting

This fiber laser cutter is mainly used to cut thin metal plates. It can automatically load, unwind, level and cut, saving manpower and greatly improving production efficiency. The price is between US$45,000 and US$95,000.

| Model |

ELECNC-1530FC |

ELECNC-1540FC |

ELECNC-2040FC |

| Total machine weight |

6.2t |

6.7t |

6.9t |

| Working area (mm) |

1515*3030 |

1515*4040 |

2020*6060 |

| Max. acceleration |

1.5G |

1.5G |

1.5G |

| Worktable |

Rolling blade |

Rolling blade |

Rolling blade |

| Positioning accuracy |

±0.05mm |

±0.05mm |

±0.05mm |

| Repositioning accuracy |

±0.03mm |

±0.03mm |

±0.03mm |

| Laser power |

1kW - 2kW |

1kW - 2kW |

1kW - 2kW |

| Coil sheet thickness |

0.5-3mm |

0.5-3mm |

0.5-3mm |

| Machine bed |

Plate welded bed |

Plate welded bed |

Plate welded bed |

| Laser |

Multiple options |

Multiple options |

Multiple options |

| Focusing method |

Auto/manual |

Auto/manual |

Auto/manual |

| X/Y-axis max. linkage speed |

140m/min |

140m/min |

140m/min |

| Leveling speed |

≤20m/min |

≤20m/min |

≤20m/min |

| Coil weight |

≤15t |

≤15t |

≤15t |

Dual Purpose Sheet and Tube Laser Cutting Machine Fiber Laser Cutter for Steel, Aluminum, Titanium, Copper

This machine is an ideal entry-level fiber laser cutter that can cut both metal sheets and tubes, saving floor space and improving work efficiency. The price is between $25,000 and $60,000.

| Model |

ELECNC-1530FT |

ELECNC-1560FT |

ELECNC-2060FT |

| Working area (mm) |

1515*3030 |

1515*6050 |

2020*6050 |

| Worktable bearing capacity |

900kg |

1500kg |

2000kg |

| Positioning accuracy |

±0.03mm |

±0.03mm |

±0.03mm |

| Repositioning accuracy |

±0.02mm |

±0.02mm |

±0.02mm |

| Pipe section shape |

Round/square/rectangular |

Round/square/rectangular |

Round/square/rectangular |

| Max. length of pipe |

3m/6m |

3m/6m |

3m/6m |

| Laser power |

1kW - 6kW |

1kW - 6kW |

1kW - 6kW |

| Laser |

Multiple options |

Multiple options |

Multiple options |

| Max. acceleration |

1.5G |

1.5G |

1.5G |

| Max. running speed |

140m/min |

140m/min |

140m/min |

Cost-effective CO2 Laser Engraving Machine Fabric CO2 Cutter for Home Use at Low Cost

This CO2 laser cutter can be used to cut felt, textiles, cloth, leather, etc. It can cut straight or curved lines, works fast, has high precision, and reduces material loss. The price range is between $6,000 and $15,200.

| Model |

ELECNC1325L |

| Working area |

1300mm*2500mm |

| Color |

Blue and white |

| Control system |

RD 6445G |

| Laser power |

RECI W6, optional: W2, W4, W8 |

| Laser type |

Sealed Co2 glass laser tube |

| Cutting speed |

0-30,000mm/min |

| Position system |

Red dot |

| Graphic format |

PLT, ENG, DXF, DWG |

| Motor & drive |

Stepper |

| Accessory |

Air Pump, CW5000 Water Chiller, Lens |

| Application |

Cotton, denim, felt, flannel, fleece, jeans, lace,

leather, linen, polyester, satin, silk, softshell, wool |

| Operating temperature |

0-45℃ |

| Operating humidity |

5-95% |

Mini CO2 Laser Cutting Machine 80W Laser Cutter for Sale with Rotary Device

This 1390mini co2 laser cutting machine can be used for CNC laser wood cutting in small businesses. It can be used for both wood cutting and wood engraving. It has a fast running speed, stable operation, and high cost performance. It is small in size and relatively low in price, ranging from $3200 to $9400.

| Name |

ELECNC1390 Laser Wood Cutter Machine |

| Working area |

1300mmx900mm, optional: 600x900mm, 1600x1000mm, etc. |

| Laser power |

RECI 75-150W, Yongli 300W |

| Laser type |

Sealed Co2 laser source |

| Cooling |

CW300/CW500/CW5200/CW6000 |

| Cutting speed |

0-30,000mm/min |

| Cutting thickness |

0-25mm acrylic (others determined by materials) |

| Position system |

Red dot |

| Support fraphic format |

PLT, DWG, DXF, EN |

| Motor&drive |

Stepper |

| Working voltage |

220V, 50Hz |

| Working table |

Blade or honeycomb worktable |

| Packing |

Wooden box |

| Other |

Air Pump, Exhaust Fan, Water Pipe, Toolbox, Focus Mirror, Reflector |

Conclusion

Fiber laser cutters and CO2 laser cutters each have their own advantages and disadvantages when facing specific application requirements. At present and for a period of time in the future, fiber lasers and CO2 lasers cannot replace each other, but can only coexist and complement each other. Their purchase prices are also different, and users should choose different cutting equipment according to their needs and cutting purposes. If your cutting needs are for cutting metals, then the fiber laser cutting machine is your choice. If you use it to cut non-metals, then the co2 laser cutting machine is your choice. I hope this article can help you understand the differences between the two machines, help you choose the machine, and buy the right machine for you.