The laser cutting machine has been rapidly developed and applied in the metal processing industry in recent years. It has many advantages such as fast cutting speed, narrow cut width, wide application, and high precision. However, the requirements for the cutting quality of laser cutting machines are getting higher and higher. That's because of the development of production and the application of new processes. This puts forward higher requirements for the quality of the CNC laser cutting machine.

The cutting process of a CNC metal laser cutter is complex with a lot of affecting factors. So, the cutting quality and precision of a laser cutting machine will be affected greatly in case of improper control. This may result in unsatisfactory cutting quality. Therefore, it is necessary to study and analyze the factors that affect the cutting quality systematically to get better results.

This article lists the criteria and factors that evaluate and impact the cutting quality of a laser metal cutting machine. It also comes with several simple but helpful solutions to improve certain defects.

Evaluation criteria of laser cutting machine cutting quality

Roughness

There will be vertical lines on the laser cut section. And the depth of such lines determines the roughness of the laser cut surface. The shallower the line, the smoother the laser cut surface. This also means better cutting results for the laser metal cutting machine.

Burrs

The auxiliary gas will blow away the slag after the CNC laser cutting machine cuts through the metal. However, some slag will form burrs after cooling and hang on the bottom of the workpiece in the actual cutting process. This could result from many factors. These factors may include thick plates, insufficient air pressure, mismatched feed speeds, etc. Excessive burrs mean poor cutting quality of the laser metal CNC machine.

Perpendicularity

The perpendicularity can be neglected when using a metal laser cutting machine to cut thin metal sheets. But, it matters a lot when the thickness of the sheet exceeds 10mm. The laser beam becomes divergent when it moves away from the focus. Correspondingly, the cut becomes wider toward the top or bottom depending on the position of the focus. This will cause the cutting edge to deviate from the vertical line by a few hundredths of a millimeter. The more vertical the edge, the higher the cutting quality of the fiber laser cutting machine.

Cutting width

Generally speaking, the cut width does not affect the cutting quality of the metal laser cutter. It matters only when a particularly precise contour is formed inside the part. Because the cutting width determines the small inner diameter of the contour. When the thickness of the sheet increases, the cutting width of a sheet metal laser cutting machine also increases. Therefore, it is necessary to ensure that the workpiece is stable in the processing area of the fiber laser cutter.

to ensure stable high-precision cutting,

Lines

The molten metal will not appear in the cut below the vertical laser beam when cutting thick plates at high speed. Instead, it will spray out at the rear of the laser beam of the fiber laser cutting machine. As a result, curved lines are formed on the cutting edge, and the lines closely follow the moving laser beam. We can slow down the feed rate at the end of the cutting process to correct this problem.

Factors affecting laser cutting machine cutting quality

Point 1: Impact of the laser output power on cutting quality

For continuous-wave output laser cutting machines, the value and mode of the laser power will have an important impact on cutting. We often set the maximum power of the metal laser cutting machine to obtain a higher cutting speed, or to cut thicker materials. But this is not always the right choice.

Sometimes the laser beam mode (distribution of laser energy on the section) matters a lot. Furthermore, the laser mode changes a little when you increase the laser power of the metal laser cutter. It is often found that the highest power density and the best cutting quality appear at the focal point with the power less than the maximum value.

- When the laser power of the laser metal cutting machine is too small, the material heat could be insufficient. Besides, the closer to the lower edge, the lower the temperature of the molten product. Therefore, the high-pressure airflow may not blow away the slag thoroughly, resulting in them sticking to the cutting edge.

- The heat input could be excessive if the laser power of a metal laser cutter is too large. Then the molten range of the workpiece will be greater than the high-pressure airflow can blow. So, part of the molten metal remains on the sheet, resulting in overburning.

Therefore, you need to pay special attention to the laser power based on your specific cutting conditions.

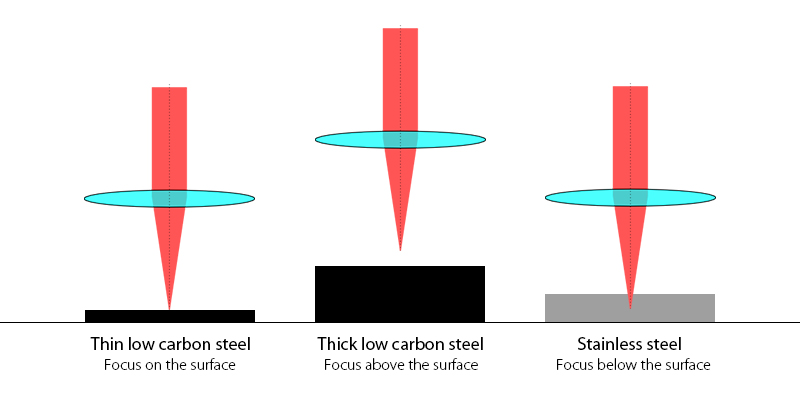

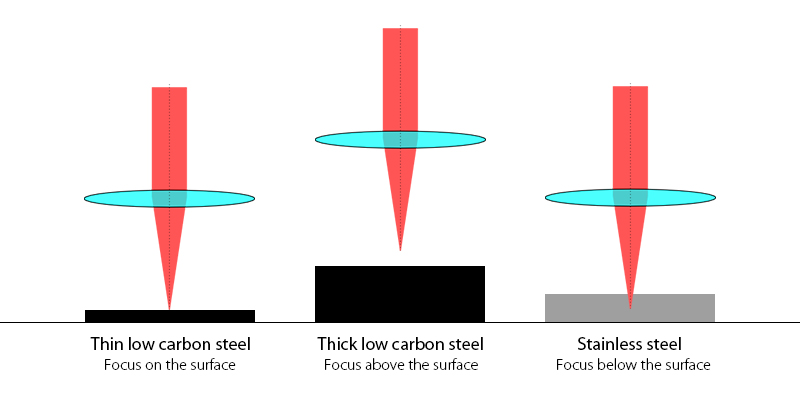

Point 2: Impact of focus position on cutting quality

It is also of great importance to select the focal length of the lens.

After the laser beam is focused, the spot size is proportional to the focal length of the lens. The spot size is small when the beam is focused by a short focal length lens. Besides, the power density at the focal point is high, which is very beneficial for material cutting. However, its focal depth is very short with a small adjustment range. So it is generally suitable for high-speed cutting of thin materials.

Conversely, a lens with a long focal length has a wide focal depth. So the CNC laser cutting machine with a long focal length lens is suitable for cutting thick workpieces. Of course, this CNC metal cutting machine should have sufficient laser power density.

The relative position of the focal point and the workpiece surface is particularly important after determining the focal length.

The focus position shall be just on or slightly below the workpiece surface in most cases. Because the focus position of the fiber laser cutter has the highest power density.

Keeping the relative position of focus and workpiece constant is an important condition to obtain stable cutting quality. Sometimes, the focal length may change because of the poor cooling of the lens of the laser metal cutting machine. Hence, we need to adjust the focus position in such cases.

It will get the narrowest slit, highest efficiency, and best cutting quality when the focus is in the right place.

In most cases, the focus of the CNC laser cutting machine is set just below the nozzle. Furthermore, the distance between the nozzle and the surface is about 1.5mm.

Point 3: Impact of cutting speed on cutting quality

The cutting speed of a fiber laser cutter follows an empirical formula for given laser power and material. So as long as it is above the threshold, the cutting speed of the material is proportional to the laser power. That means, increasing the power of a CNC laser cutting machine can increase its cutting speed. The power referred to here is related to not only the laser output power but also the beam quality mode. In addition, the spot size after focusing also has a great influence on laser cutting.

The cutting speed of a laser cutter for metal is proportional to the material density and thickness. Therefore, we can increase the cutting speed of a fiber laser cutting machine through the following methods. For example, with other parameters unchanged, increasing laser power (within a certain range). Or improve laser beam mode, decrease the spot size, or cut thin materials.

The cutting speed of the laser cutter can have a relative adjustment range with a satisfactory cutting quality under constant process variables. This adjustment range appears slightly wider when cutting thin metals with a laser metal CNC machine. Occasionally, a slow cutting speed will also cause the molten material to ablate the surface, leaving rough edges.

Point 4: Impact of auxiliary gas on cutting quality

Cutting metal sheets with a laser metal cutting machine requires auxiliary gases in general. This mainly concerns the type and pressure of the auxiliary gas. Usually, the auxiliary gas is ejected coaxially with the laser beam. It protects the lens of the fiber laser cutter from contamination. Meanwhile, it also blows away the slag at the bottom of the cutting area.

Most laser cut metal operations adopt active gases (mainly O2) to produce an oxidation reaction with the heated metal. The additional heat generated hereby may improve the cutting speed of a metal laser cutter by 1/3 to 1/2.

We need to supply high-pressure gas when cutting a thin sheet with a fiber laser cutting machine. This avoids the slag from sticking to the back of the cutting slit, causing damage to the edges. Accordingly, we need to reduce the gas pressure when cutting thick sheets or at a low speed.

Practice shows that when the auxiliary gas is O2, its purity has a significant impact on the cutting quality. The cutting speed will reduce by 50% if the purity of O2 reduces by 2%. Meanwhile, this also debases the cutting quality of the laser metal cutting machine.

Tips to improve the laser cutting machine cutting quality

You may encounter various troubles when using a laser cutter for metal. For example, rough edges, burrs, deformation, failure in cutting through, color changing, etc. Each trouble requires you to check the cutting parameters or conditions of the metal laser cutting machine.

In case of the following four troubles, please check your metal CNC machine first according to the given methods. If the problems still exist after self-checking the machine, you need to contact the machine supplier or consult the professionals.

To reduce burrs

First, check whether there is something wrong with the laser output of the fiber laser cutter. Remember to check whether the spot is round and whether the spot is coaxial with the center of the nozzle.

Then, check whether there are foreign matters on the optical system of the fiber laser machine. For example, fine particles, dust, or slag on the lens. Be sure to check if the lens has tiny cracks. All these can affect the transmission of the laser power.

Consider changing the cutting parameters of the laser cutter or purity of the gas if the above problems are solved. You may find the appropriate cutting parameters through multiple cutting practices.

To avoid deformation

The area around the cut is heated when cutting metal with a fiber laser cutter. At the same time, the structure of the metal changes. For example, some metals may harden after being cut by a laser CNC metal cutting machine.

Any dent or corrosion has a detrimental effect on the cutting edges of the metal laser cutting machine. And they belong to the cutting errors that should generally be avoided. The metal will deform if it heats up sharply during the cutting process.

To avoid deformation, you can control the laser power or use a short laser pulse to reduce the heating up of the metal. This is particularly important in fine machining, where contours and webs are usually very narrow.

To solve the failure in cutting through

You can try to slow down the cutting speed of the CNC metal laser cutter properly. Besides, clean the contaminated reflecting lens timely and properly and replace the focusing lens.

Re-adjust the optical path of the CNC laser cutting machine. Hence, adjust the focus until the laser spot is concentric with the center of the nozzle.

When cutting copper and aluminum, you polish the surface in advance to deal with the problem of high reflectivity.

Remember to clean the debris inside the laser metal cutting machine nozzle timely. Increase or decrease the gas pressure according to the actual situation. What’s more, replace the distilled water in the cooling system in time.

To solve the color change

The color change near the cut is mainly due to the oxidation of the material at high temperatures. For instance, stainless steel is not only a high-temperature resistant material but also a thermal insulation material. Because it has poor thermal conductivity. So a high temperature will be generated and accumulated near the cut when we cut it with a laser cutter for metal. Thus, the stainless steel at a high temperature will oxidize in the air. Depending on the temperature, the depth of oxidation is also different, resulting in different colors.

Apart from the above, slow cutting speed, improper focus, or gas purity can also cause color changes of metals.

You can try the following methods to reduce the color change:

- Cool the materials if they are too hot.

- Increase the feed rate.

- Test with the locator and adjust the focus to a proper position.

- Increase the auxiliary gas pressure.

- Use high-quality and purity N2.

Laser cutting machine recommendation

Sheet metal laser cutting machine

Except for the dedicated tube metal laser cutter, all other laser CNC machines can cut metal sheets. Among them, the most popular one is the open flatbed laser cutting machine.

We have many worktable sizes for you to choose from. To name a few, 1515x3030mm, 1515x4040mm, 1515x6050mm, 2020x4040mm, and 2020x6050mm. Besides, you can also customize many other specifications based on your specific cutting requirements. For example, laser power/brand, laser head type/brand, motor brand, focusing method, etc.

Among all the sizes, 1530 is the most popular. Because it’s relatively cheap and the size of 1515x3000mm can meet most of the laser cutting demands. Many metalworking shops use this fiber laser cutter to cut metal doors, windows, fences, etc.

Let's see how our laser CNC machine cuts the highly-reflective material — brass.

Tube and sheet metal fiber laser cutting machine

It combines two functions into one laser metal cutting machine. Half of the machine is to cut metal sheets, and the other half is to cut metal pipes. It uses double pneumatic chucks to hold and rotate the tubes and pipes steadily.

Check out how the dual-use fiber laser machine work to cut steel and brass sheets and also tubes.

Precision fiber laser cutting machine

This type of fiber laser machine has a big cover but a relatively small working size. It can complete metal sheet cutting work with extremely high precision. The precision fiber laser machine is mainly for cutting thin metal sheets.

We provide five models for the precision CNC metal laser cutter, such as 6060, 9060, 9090, 1390, and 1313. These numbers refer to the worktable size as 605x605mm, 905x605mm, etc.

Watch the video below to see the cutting process if you are interested in this laser cutting machine. Contact me to get a quote.

Conclusion

This article describes the major 4 factors that affect the cutting quality of a fiber laser cutter. In addition, there are also other factors. For example, the reflection rate, the material surface condition, etc. All these factors can affect the absorption of the laser beam by the metals.

The nozzle diameter, the distance between the nozzle and workpiece, optional paths of the metal laser cutter also matter.

Therefore, I summarize the factors impacting the laser cutting machine cutting quality briefly in the following table:

| Factors that affect the laser cutting machine cutting quality |

| Major factors |

Laser power and mode |

| Focal position |

| Cutting speed |

| Auxiliary gas |

| Other factors |

Material condition

Nozzle

Optical system

Etc. |

In summary, the laser power and mode, focus position, cutting speed, and auxiliary gas pressure are the four most important variables. If you find obvious deteriorated cutting quality during the cutting process, check the following 4 factors first. In case of any abnormality, control and adjust in time.

Many problems may occur inevitably in the actual operation process despite how good the laser cutting machine is. So, if you encounter any problem when using our laser cutting machine, don’t hesitate and contact me immediately. We will try our best to provide timely solutions.