With the development of technology, the laser cutting machine price may no longer be prohibitive for small factories. Although laser cutting machines were once something that only large companies could afford, there are now more affordable models on the market. Even so, the laser cutting machine price is far from cheap. Then why do people choose laser cutting machine instead of other cutting methods? This is because the laser cutting machine has unique advantages and functions. Even with a high laser cutter machine price, people are willing to buy it.

This article offers you a general range of laser cutting machine price, and lists the major factors affecting the laser cutter cost. At the end of this article, it also recommends two laser cutting machine with a low laser cutter price. They can meet your requirements of cutting both metal and non-metal materials.

Laser cutting machine price range

The laser cutting machine price varies from thousands of dollars to hundreds of thousands of dollars. For small factories, this price is still a bit expensive. However, we should know that we can't just care about the laser cutting machine cost when buying a laser cutter. We need to take a variety of factors into consideration, including production cost, efficiency, etc.

Before understanding the price range, let us look at the types of laser cutting machines first.

Currently, there are major three types of laser cutting machines on the market: fiber laser cutting machine, CO2 laser cutting machine and YAG laser cutting machine. YAG laser cutting machine can cut metal materials, but its photoelectric conversion efficiency is only about 3%. This is far smaller than that of the fiber and CO2 laser cutters. So its energy consumption is large, and it requires frequent maintenance. Besides, the fiber laser cutter can cut the same metal materials as the YAG laser cutter but with less energy consumption and maintenance. So people tend to choose the laser cutting machine gradually.

Therefore, the most commonly used laser cutters are fiber laser cutting machine and CO2 laser cutter. The laser cutting machine price range of the two is as follows:

| Type |

Price range |

| Fiber laser cutting machine |

$30,000-$200,000 |

| CO2 laser cutting machine |

$3,000-$60,000 |

Fiber laser cutting machine price

Fiber laser cutting machine is a laser cutting machine that uses a fiber laser generator as the light source. The fiber laser generator can output a high density laser beam, which can be focused on the surface of the workpiece. The area irradiated by the focus spot on the workpiece is melted and vaporized instantaneously. Move the laser spot by the numerical control mechanical system to realize automatic cutting.

Due to the high cost of a laser generator, the fiber laser cutting machine price is relatively high, ranging from $30,000 to $200,000. The price difference of fiber laser cutting machines mainly lies in the power of fiber laser generator, and the size and components of the fiber laser cutter. The higher the power of laser generator, the higher the fiber laser cutter price. Similarly, the bigger the working size, the higher the fiber laser cutter price.

The fiber laser cutting machine usually adopts large power, such as 1,000W to 12,000W, to cut metal materials. For example, stainless steel, carbon steel, copper, etc. Generally, the fiber laser cutting machines with higher power adopts parts and components with higher configuration. So the price of high power fiber laser cutting machines may be 10 times that of the fiber laser cutter with small power.

CO2 laser cutting machine price

CO2 laser cutting machine adopts the CO2 laser beam generated by the CO2 laser tube. Its major working substance is a mixture of carbon dioxide, helium, and nitrogen. Through the focusing mirror inside the laser head, the laser beam emitted by the CO2 laser tube is focused into a high-energy laser beam for cutting.

Compared with fiber cutting machines, the CO2 laser cutting machine price is cheaper, which is about $3,000-$60,000. The price difference also mainly lies in the laser power, machine size and so on. The greater the power and size, the higher the CO2 laser cutting machine price.

Power of the CO2 laser cutters can be 50W to 2000W. They are mainly for cutting non-metal materials. For example, wood, acrylic, glass, leather, crystal, paper, plastic, etc. Co2 laser cutters with high laser power can also cut thin metal sheets.

Factors that affect laser cutting machine price

Laser cutting machine price consists of several parts, including the machine cost, freight, service fees, etc. If you buy a laser cutting machine from abroad, the laser cutting machine cost may also include shipping fee, tax fee, custom clearance fee and so forth.

The factors that affect the laser cutting machine cost fall into two aspects, i.e. internal factors and external factors. The internal factors relate to the laser cutter itself. While the external factors involve the additional fees pertaining to transportation, service, tax, etc.

The factors relating to the laser cutter itself that affect the laser cutter price include:

1. Parts and components

A laser cutting machine is composed of various parts and components. For instance, laser generator, motor, laser lenses, laser tube, water chiller, control system, etc. The cost of all these parts will affect the laser cutter cost.

Laser generator or laser tube

Laser generator or laser tube is the core part of a laser cutter. The laser generators or tubes of different brands and quality have different prices. The service life of high-quality laser tubes can reach 10,000 hours. In addition, the power of the laser generator is also one important factor that affects the laser cutting machine cost. The greater the power, the higher the laser generator price. The greater the cutting speed and the thickness of the cutting material, the higher the laser cutter cost. The high cost of the laser generator accounts for a large part of the laser cutting machine price.

Motor

Motor relates to the precision of a laser cutting machine. The cost of a famous brand motor differs from that of a common brand motor and the precision of the laser cutting is also different. High-precision laser cutting machine price is greater than that of a low precision laser cutter.

Optical lenses

The laser beam emitted by the laser generator needs to be refracted and focused by optical lenses. Especially CO2 laser cutting machine requires multiple complicated optical lenses. There is a big difference in the price of lenses, and also in effectiveness and service life. High-quality lenses causes extra cost to the laser cutting machine price.

Machine frame

Some laser cutting machine manufacturers use thin iron sheets to make machine housing in order to save cost. But after being used for a period of time, the thin iron housing will deform, which could seriously affect the cutting accuracy of the laser cutting machine. A good laser cutting machine should adopt a frame structure welded with high-quality steel, and the housing made of high-quality cold-rolled steel plate. This will also increase the laser cutting machine price.

2. Types of laser cutting machines

Different types of laser cutting machines have distinct photoelectric conversion efficiency, cutting speed, accuracy and quality. The photoelectric conversion efficiency of fiber laser cutters is the highest, which can reach 25%. And that of CO2 laser cutters is about 10%. So in case of the same laser power, the fiber laser metal cutting machine price is the highest among these three types.

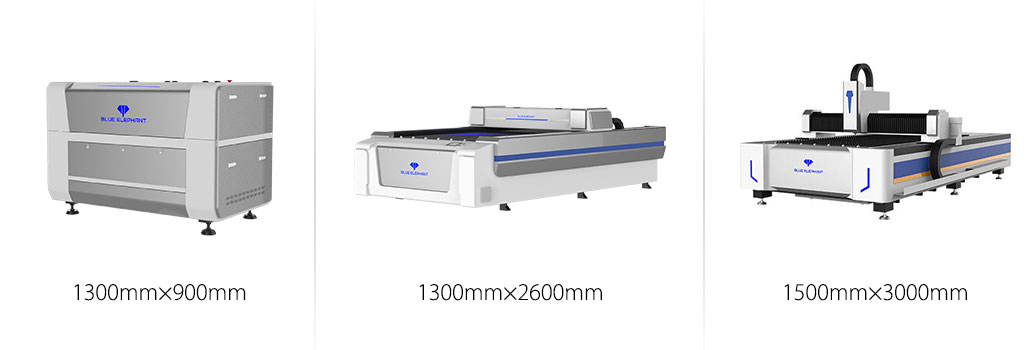

3. Working size

Even though the same model and same power, the laser cutting machine cost of different working sizes is different. Because the larger the machine working size, the higher the production cost. Hence the laser cutting machine price is higher.

Except for the factors related to the CNC laser cutter itself, the external factors affecting the laser cutting machine cost include:

1. Brand

In order to win in the competition, companies must carefully maintain the goodwill of their brand. Laser cutting machine manufacturers tend to strictly control product quality so as not to damage their brand. The brand influence of the laser cutting machine is reflected in the quality, operation and service of the laser cutting machines. Large-brand laser cutting machines usually use famous laser generators, motors, water chillers and other accessories to ensure the stable operation of laser cutting machines. Moreover, the quality and service of laser cutting machines of big brands is effectively guaranteed. Correspondingly, famous brand laser cutting machine price will be higher.

2. After-sales service

This is also an important factor that affects the laser cutting machine price. All-round services offer customers with machine safety and timely maintenance of laser cutters. The laser tube and reflector of the laser cutting machine are all consumables, which have a certain service life and need to be replaced when they expire. This requires the manufacturer to provide a strong after-sales service guarantee and provide these consumables in a timely manner. Laser cutting machine manufacturers with good after-sales service have relatively high prices for laser cutting machines.

3. Shipping fee, tax fee, customs clearance fee

These fees are also part of the total laser cutting machine price. Buying a machine from your own country may not need to pay customs clearance fees and related taxes. But if you buy a machine from abroad, you need to pay extra shipping fees, customs clearance fees and other expenses. This also increases the laser cutter price.

Buy a laser cutting machine VS. choose laser cutting service

Regardless of a CO2 laser cutter or a fiber cutting machine, a desktop model or a multi-function laser cutting machine, it is definitely an expensive purchase. In addition to the CNC laser cutting machine price, you also need to pay additional maintenance cost, electricity cost, and the cost of time spent on learning operations. Many people may think that it is better to choose laser cutting services than to pay for the expensive CNC laser cutting machine price.

But in my opinion, there are many benefits of buying a laser cutting machine. In case that you need to cut something, you can switch on the laser cutting machine to cut at any time. You don’t need to wait for the laser cutting service provider to be available. If the service provider is currently not available, you may have to wait for their schedule. However, when you have a laser cutting machine, it’s more convenient.

There are many companies providing online laser cutting service currently. But the cutting quality is uneven. You may need to spend quantity of time and money to experience their laser cutting service before you find a satisfied cutting service. Although buying a CNC laser cutter requires you to pay for the expensive laser cutting machine cost, it can help you obtain stable cutting quality in mass production. And it can improve your processing efficiency and increase output.

For companies with purchasing power and large output, it is cost-effective to buy a laser cutting machine. But small workshops or enthusiasts may not be able to afford the expensive laser metal cutting machine price. They can choose laser cutting service now and buy their own laser cutters when they have saved enough money.

Buy a new laser cutter VS. buy a used laser cutter

Due to the expensive laser cutting machine price, some people may consider to buy a used laser cutter machine. As far as I know, except for the price advantage, buying a used laser cutting machine has other risks.

In case that the second-hand laser cutting machine you bought runs well, it can meet your cutting requirements. This is good. But in case, although the second-hand laser cutting machine you bought looks good in appearance, many problems appear during the cutting process. And your seller can't solve these problems or you even lose contact with him. Then your loss will be great.

Hence, I suggest you to spend a bit more money to buy a brand new laser cutting machine to avoid the above risks. Although the new laser cutting machine price is high, it has stable performance, high cutting speed, precision and quality. It can perfectly meet your requirements. In addition, the good laser cutting machine manufacturers will provide you with all-round service before and after the sale. They will try their best to solve any problem you encountered.

Laser cutting machine recommendation

As one of China's top laser cutting machine manufacturers, Blue Elephant offers CO2 and fiber laser cutting machines of multiple sizes. Our CO2 laser cutting machine is suitable for cutting and engraving non-metal items. Small-sized CO2 laser cutter price is relatively cheap. Our fiber laser cutting machines with high power can cut up to 25mm thick metal sheets. The fiber laser metal cutting machine price is high correspondingly.

Laser cutting machine price shall not be the only criterion when buying a laser cutting machine. Because the cost also tends to reflect in the reliability. At the same time, going for the highest possible grade would probably need sufficient usage of the machine to justify the laser cutting machine cost.

I'd like to introduce two models of Blue Elephant low cost laser cutter. Blue Elephant has been committed to CNC machine production for over 10 years. Blue Elephant laser cutting machines have obtained positive comments from all over the world by virtue of the good quality.

CO2 Laser Cutting and Engraving Machine for Sale

This is a new appearance 1390 CO2 laser cutting machine. Based on different laser power and working size, the CO2 laser cutting machine price is about $3,000-$9,000. It is a multifunctional laser machine that can cut, engrave, etch and mark. At the same time, this CO2 laser cutter is also equipped with a rotating device. So it can engrave cylindrical parts, such as glass cups. This machine is good at processing non-metallic materials, such as wood, acrylic, paper, MDF, glass, etc.

learn more

Fiber Laser Metal Cutting Machine

Words in the end

Laser cutting machines have advantages of high efficiency, high precision and high cutting quality. As far as current laser technology is concerned, the laser cutting machine price is not affordable for every metal worker. Even so, many metalworking companies, especially large manufacturing companies, are willing to pay for this investment. Because the benefits brought by laser cutting machines may far exceed the laser cutting machine price.

Before buying a laser cutter, you need to do some preparations. First, you need to figure out your cutting requirements and decide you need a fiber laser machine or a CO2 laser cutter. The laser cutter machine price difference of the two is quite large. Then you need to choose a right laser cutting machine manufacturers. I would not advise to make the choice based on the cost only. Because I believe that you get what you pay for. Low-priced laser machines are likely to use poor-quality parts, resulting in high maintenance costs in later use.

If you are not in tight budget, and eager to improve the cutting efficiency and precision, laser cutting machines are an excellent choice. Despite the expensive laser cutting machine price, the benefits it brought will soon make up for this investment.