2030 Solid Wood CNC Cutting Machine

1530 Furniture 3-Axis Cutting Machine

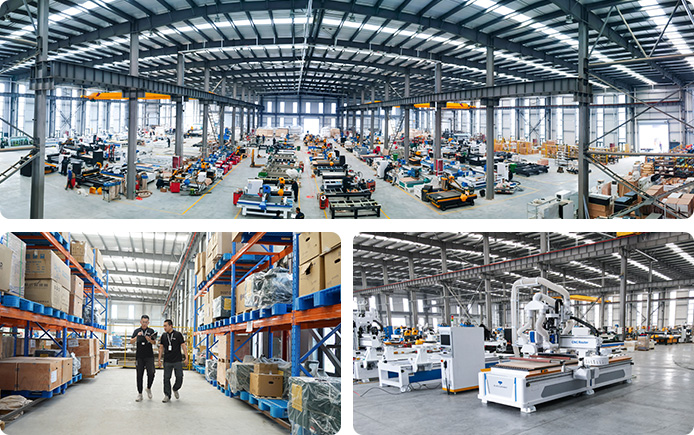

This CNC router machine is an upgraded version of the ordinary 3-axis CNC router. It is designed to provide customers with a better service from the appearance to the performance.

1. The appearance of the machine is simple and generous, showing the beauty of technology.

2. Adopting heavy-duty bed, it is thicker, stronger, more stable and durable.

3. Adopting DSP A11 control system, it has the advantages of simple operation, convenient use, low cost, etc.

4. Support customized services. The bed, working size and machine configuration of the machine can be customized according to production needs.

| Model | ELECNC2030 |

| X,Y axis travel | 2000x3000mm option: 1300*2500mm; 1500*3000mm; 2000*4000mm, etc |

| Z axis travel | 200mm, option: 300mm, 400mm, 500mm, 600mm, etc |

| Spindle type | 6.0kw HSD air cooling spindle, ER32 |

| Inverter type | 7.5kw |

| Drilling bank | Taiwan or Italy 5+4 verticaldrills |

| Tool magazine | Linear type auto tool changer Option: Carousel type auto tool changer |

| Tool holder with collet | ISO30, ER32 collet: φ4, φ6, 1/8, 1/2 |

| Control system | DSP controller, option: Taiwan SYNTEC/LNC |

| Driving system | 850w YASKAWA servo motors and drivers Option: 1kw Taiwan Syntec servo |

| Reducer | Japan SHIMPO reducer |

| Machine structure | Heavy duty body with quenching treatment |

| Work table | Aluminum T-slot & vacuum work table |

| Positioning cylinder | 5 pieces (X2, Y3) |

| Linear guide | Taiwan linear guide with dust proof |

| Transmission | X,Y axis: Taiwan / Germany Helical Rack and Pinion Z axis: Taiwan TBI high precision ball screw |

| Lubrication system | 1.5L automatic lubrication system |

| Tool calibration | Manueltool sensor calibration |

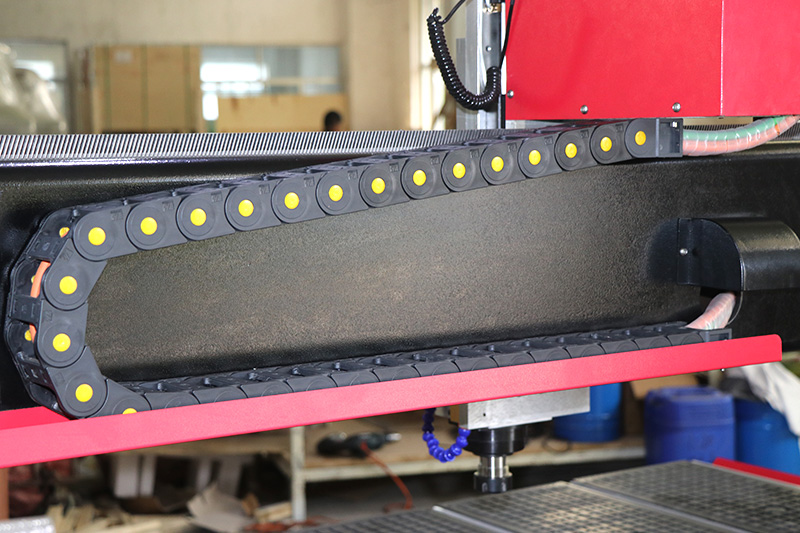

| Cables | Germany Igus cables with CE, cUL certificate |

| Compatible software | Artcam, Alphcam, Type 3, Ucancam, Aspire, etc |

| Command language | G Code & M Code |

| Traveling speed | 80m/min |

| Working speed | 0-25m/min |

| Re-positioning accuracy | ±0.03mm |

| System resolution | ±0.0025mm |

| Working accuracy | ±0.03mm |

| Working air pressure | 0.6MPa |

| Working voltage | 220V 1PH/3PH 50HZ/60HZ 380V 3PH 50HZ/ 60HZ |

| Vacuum pump |

|

| Dust collect system |

|

| Air compressor | Pistonaircompressor, screw air compressor |

| Protection device | Light curtain |

| Spindle type | 9kw ATC spindle (HSK F63),12kw (ISO30, HSK F63), etc |

Click for details

Towline

Limit Switch

Automatic Lubrication System

Motor

Click for solution

Click for quotation