Upgraded Automatic E-80L Laser Edge Banding Machine

New Design E-80 Automatic Edge Banding Machine

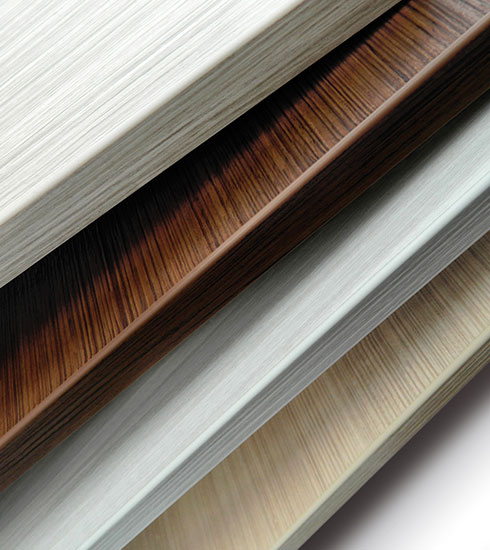

The E-80L is a fully automatic laser edge banding machine. It does not need a glue application system. The edge bander uses laser technology to bond the board with the edge banding tape, creating a seamless, glue-line-free finish. It has a maximum processing speed of 23 m/min. The tracking chamfering speed is 18 m/min. The machine is fully functional and system-stable and has intelligent operation controls. These features enable high-speed and efficient production.

1.The laser edge banding machine utilizes high-power laser edging. It eliminats the need for preheating adhesive, enabling instant edging, saving time and effort.

2.Equipped with four high-speed motors, it can achieve quick and accurate rounded edge profiling. It also has various chamfering and edge finishing techniques.

3.Dual guide rails for rapid end cutting. Through precise linear guide motion, automatic tracking of the mold and high-frequency and high-speed motor fast cutting structure, the cut surface is guaranteed to be smooth.

4.Dual reciprocating buffing to remove excess adhesive and debris of the board.

5.Pneumatic dual scraping eliminates trimming marks, ensuring the board surface is smooth and clean.

| Model | E-80L |

| Machine weight | 4550kg |

| Overall size(Length×width×height) | 10580× 960× 1600mm |

| Total power | 25KW |

| Working pressure | 0.7Mpa |

| Feed speed | Low 18/Mid 23/High 28m/min |

| Panel width | ≥60mm |

| Panel thickness | 9mm-60mm |

| Panel length | ≥ 60mm(No milling) ≥ 150mm(Pre-milling) |

| Min. size | 60×60mm |

Click for details

6-Post pressure rollers

Control panel

Tracking and rounding

Edge bander part

Click for solution

Click for quotation