E-70JDSR Automatic Avoidance Edge Banding Machine

2024 New Design E-80 Automatic Edge Banding Machine

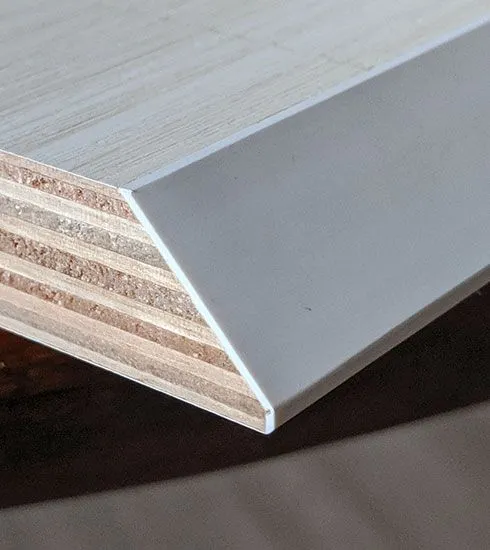

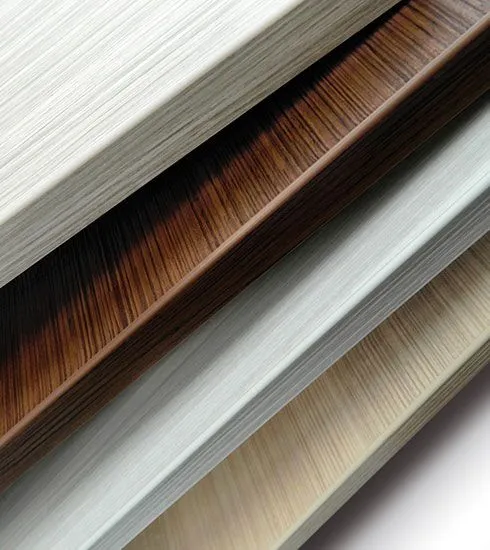

The E-70J edge banding machine automatically performs processes like pre-milling, gluing, edge banding, end trimming, rough trimming, fine trimming, tracking and rounding, scraping, polishing, and cleaning. It is widely used in the wood furniture industry, including panel furniture, custom furniture, cabinets, wardrobes, and office furniture. This edge bander machine can process MDF, eco-board, plywood, particleboard and solid wood panels.

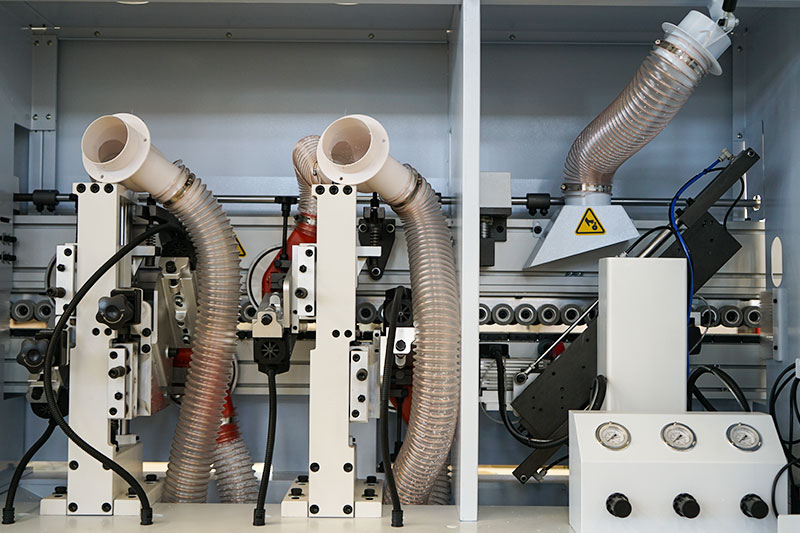

1.Pre-milling smoothens the board edges and removes residue for even glue application and thinner glue lines.

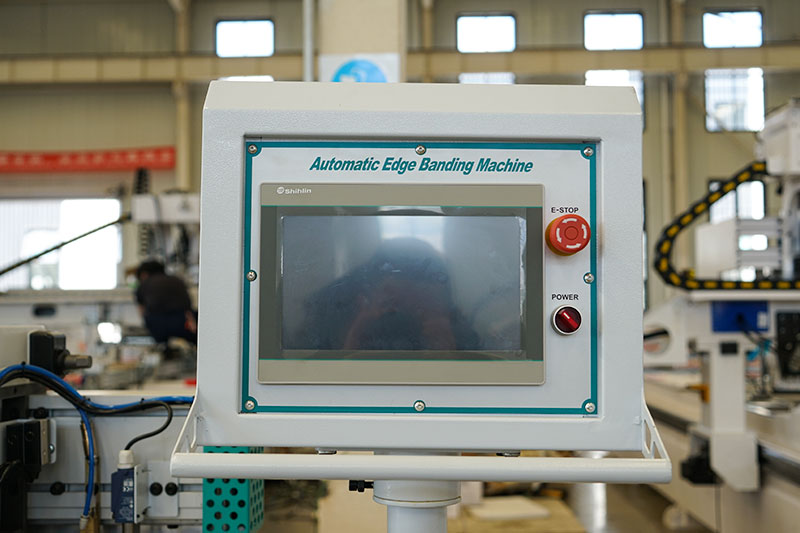

2.The touchscreen is clear and user-friendly, allowing quick switching with fast response.

3.The high-speed motor cuts quickly, cutting off and trimming the protruding edge banding strips at the front and back of the plate to ensure a smooth and flat cut surface.

4.The machine is equipped with a high-speed motor, which can perform a variety of chamfering and trimming processes to achieve more beautiful arc trimming. The independently designed tracking motion and air path make the tracking and trimming process more stable.

5.The polishing wheel rotates at high speed to polish the residual glue and debris on the edge banding plate to ensure a smooth edge banding end surface.

| Model | E-70J |

| Machine weight | 2400kg |

| Overall size(Length×width×height) | 6720× 960× 1600mm |

| Total power | 17KW |

| Working pressure | 0.6Mpa |

| Feed speed | Low 16/Mid 18/High 23m/min |

| Panel width | ≥60mm |

| Panel thickness | 9mm-60mm |

| Panel length | ≥ 60mm(No milling) ≥ 200mm(Pre-milling) |

| Min. size(Width×length) | 60×60mm/150×200mm(Pre-milling) |

| Tape thickness | 0.4mm-3mm |

Click for details

Control system

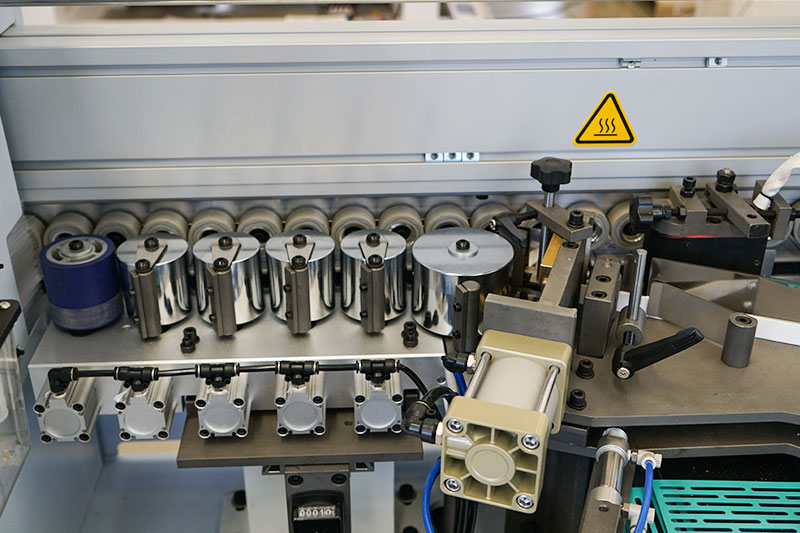

Press Roller

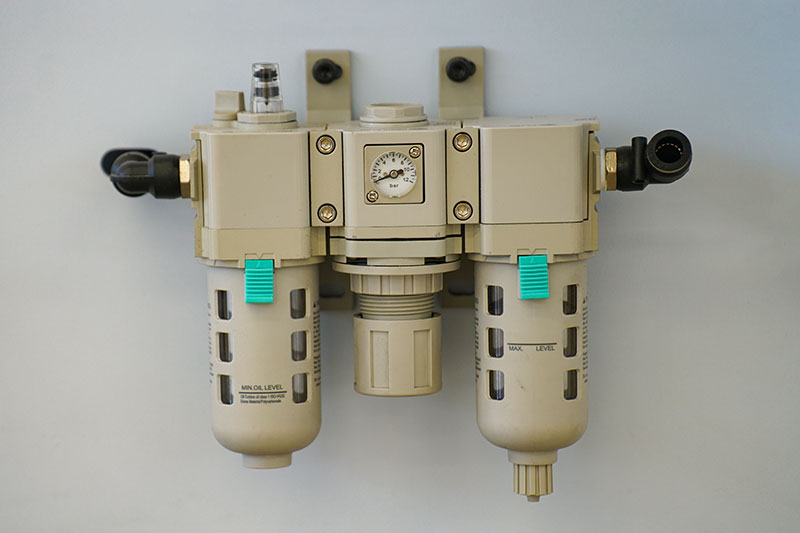

Oil-water separator

Rough trimming and fine trimming

Click for solution

Click for quotation