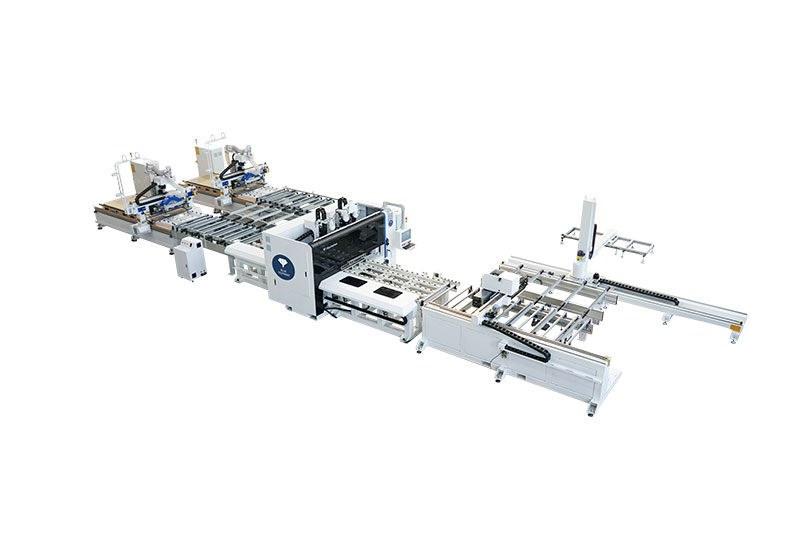

ET7.2 Labeling CNC Drilling and Cutting Production Line

ET7 Labeling CNC Drilling and Cutting Production Line

This labeling CNC drilling and cutting production line can complete automatic labeling, cutting and drilling in one go, eliminating the traditional production line's six-sided drilling or side hole machine drilling process. It uses a double drill unit for faster drilling, achieves one-time positioning and upper and lower drilling, does not require flipping the board.

1.The operation is easier and the degree of automation is higher, including automatic labeling, drilling and milling, and automatic edge sealing and punching.

2.It uses upper and lower double drills to drill holes, which is faster and more efficient.

3.It adopts three-station gantry loading system, which is faster and more efficient.

4.The production line simplifies the process and reduces the movement and handling of panels during the production process, saving effort and reducing damage to the panels.

| Machine size | 16200*3300*2600mm |

| System | Blue Elephant custom system |

| Air pressure | 0.6-0.8MPa |

| Voltage | 380V/3P/50HZ |

| Power | 40KW(Vacuum pump and vacuum cleaner not included) |

| Minimum processing size | 2800mm*1220mm*12mm |

| Maximum processing size | 2800mm*1220mm*30mm |

| Machine weight | 7.5t |

| Labeling Unit | |

| Printer | Honeywell P×240 |

| Guide rail | Taiwan square rail 20 |

| Rack | J&T 1.5M |

| Servo motor | Domestic 750W |

| Reducer | Shimpo |

| Loading table | Standard |

| Drilling and Grooving Unit | |

| Spindle | 3.5KW HQD air cooling spindle*2 |

| Guide rail | Taiwan square rail 25# |

| Drill | Changchuan 3*3 drill*2 |

| Rack | J&T 1.5M |

| Table | Roller + Air floating table(phenolic resin board) |

| Reducer | Shimpo |

| Servo motor | Domestic 750W |

| Lead screw | 2510 |

| Inverter | Fuling inverter |

| Vacuum cleaner | Recommended 5.5KW |

| Cutting Unit | |

| Spindle | JST 9KW air-cooling automatic tool-changing spindle |

| Inverter | Fuling inverter |

| Guide rail | Taiwan square rail Y 30 XZ 25 |

| Rack | J&T 2M |

| Servo motor | Domestic 1300W |

| Table | Vacuum table |

| Reducer | Shimpo |

| Lead screw | 2510 |

| Vacuum pump | 7.5kw water circulation/Becker 5.5KW 250m³/h |

| Positioning cylinder | 2+4 standard |

| Vacuum cleaner | Recommended 5.5KW |

| Unloading table | Standard |

Click for details

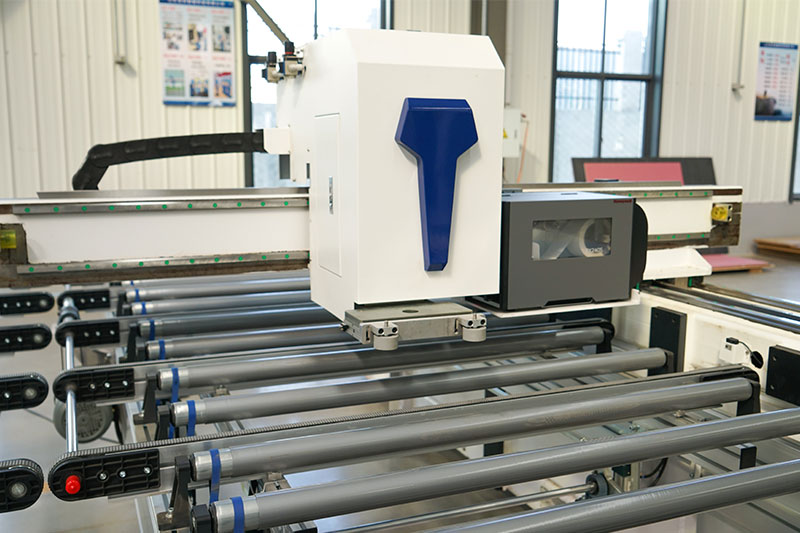

Labeling,CNC Drilling and Cutting Production Line Part

Labeling,CNC Drilling and Cutting Production Line Part

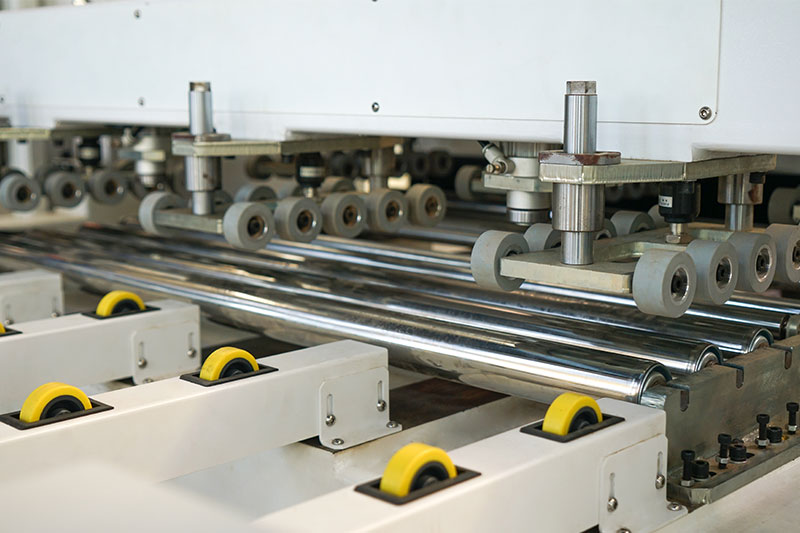

Labeling,CNC Drilling and Cutting Production Line Part

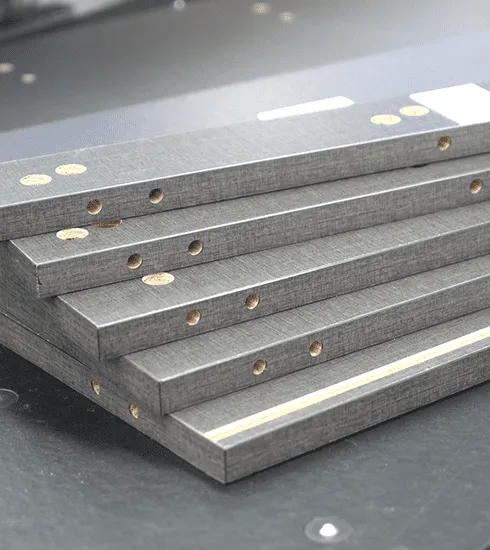

Labeling,CNC Drilling and Cutting Production Line Part

Click for solution

Click for quotation