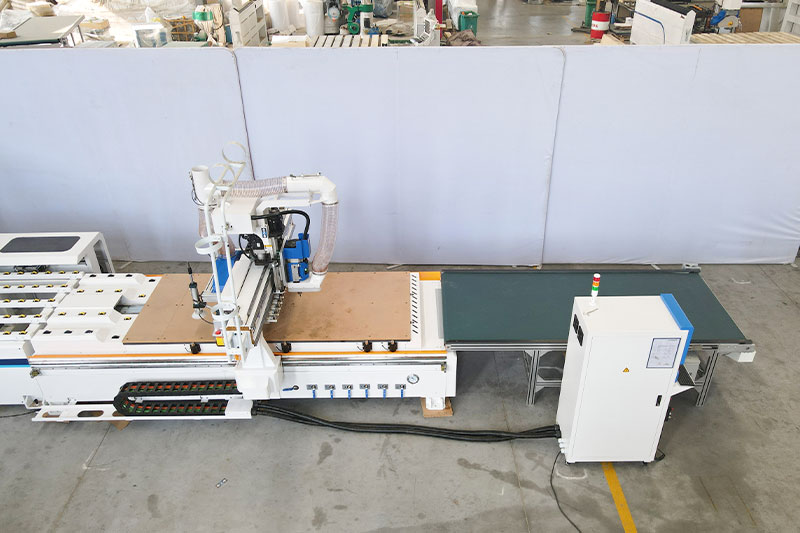

Labeling CNC Drilling and Cutting Production Line

Demonstration of CNC Drilling and Cutting Machine

ET7 labeling CNC drilling and cutting production line is a mechanical equipment that integrates drilling and cutting functions. It is widely used in woodworking, wood furniture, hone cabinets, interior doors designs and manufacturing, building decoration and other industries. Its design structure enables two different processing tasks to be completed on one machine, improving production efficiency and work efficiency.

1. Process optimization: The ET7 labeling CNC drilling and cutting production line integrates labeling, drilling and cutting at one time. And cooperating with the edge banding machine, it will eliminate many unnecessary machining processes and greatly improving processing efficiency.

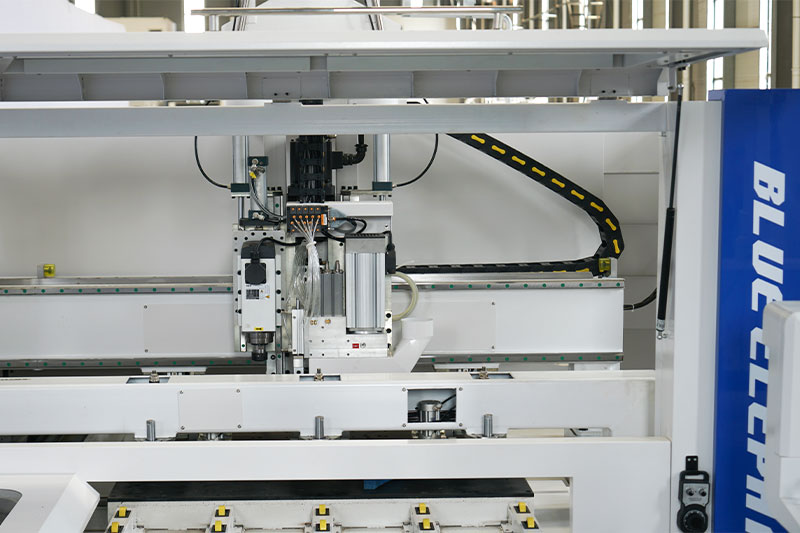

2. High processing efficiency: Upper and lower double drills make drilling faster.

3. Simplify the process flow: During the production process, the process of moving and handling panels is reduced, saving labor and effort, and reducing the risk of panel damage.

| Machine size | 16200*3300*2600mm |

| System | Blue Elephant custom system |

| Air pressure | 0.6-0.8MPa |

| Voltage | 380V/3P/50HZ |

| Power | 40KW |

| Minimum processing size | 2800mm*1220mm*12mm |

| Maximum processing size | 2800mm*1220mm*30mm |

| Labeling Unit | |

| Printer | Honeywell PX240/Zebra |

| Guide rail | Taiwan square rail 20# |

| Rack | J&T 1.5M |

| Servo motor | Domestic 750W |

| Reducer | Shimpo |

| Drilling Unit | |

| Spindle | 3.5KW HQD air cooling spindle |

| Guide rail | Taiwan square rail 25# |

| Rack | J&T 1.5M |

| Motor | 750W servo motor |

| Reducer | Shimpo |

| Inverter | Fuling inverter |

| Vacuum cleaner | 5.5KW |

Click for details

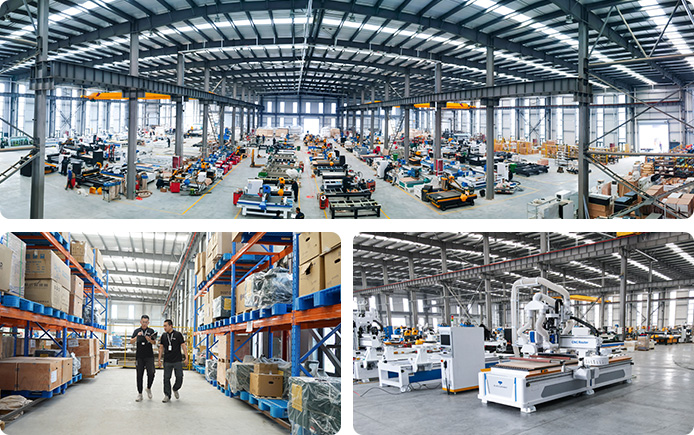

ET7 Labeling CNC Drilling and Cutting Production Line kits

ET7 Labeling CNC Drilling and Cutting Production Line part

ET7 Labeling CNC Drilling and Cutting Production Line kit

Click for solution

Click for quotation