EK2-1328 Linear ATC CNC Machining Center

New Look 1328 Nesting CNC Router

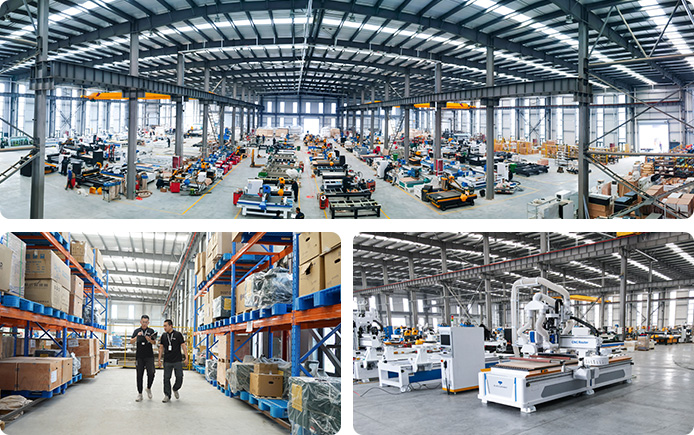

This Linear ATC CNC machining center adopts a new large square tube seamless welded bed and widened square tubes. It is also added reinforced square tubes. This structure improves the bed and table strength. In addition, this nesting cnc machine is equipped with a high-power auto tool change spindle and a fast linear tool change magazine. It is a CNC wood cutting machine that can solve various woodworking processing processes.

1. 12-tool linear auto tool magazine saves tool changing time and improves work efficiency.

2. This nesting CNC machine adopts Taiwan SYNTEC controller, which has good compatibility. Besides, it is equipped with a handle for easy operation.

3. The vacuum work table is divided into 7 areas. Each area is controlled by a control threshold, which effectively prevents the board from sliding during operation.

4. The auxiliary pushing device makes material unloading more convenient and improves production efficiency.

5. The air pressure detection system can immediately generate an alarm when the air pressure is insufficient, stop working, and protect important components .

6. It is equipped with a voltage phase sequence protector to prevent damage caused by low or high voltage, and to prevent machine failure caused by wrong wiring.

| Model | EK2-1328 |

| Working area(X-Y-Z) | 1300*2800*200mm |

| Table structure | Vacuum work table(7 Divisions) |

| Control system | Taiwan SYNTEC controller |

| Supported file formats | *.g;*.nc;*.ug;*demo;*.iso;*.eng;*.cut etc. |

| Spindle type | 9kw JST air-cooling automatic tool change spindle, 24000r/min |

| Inverter | 11kw Fuling inverter |

| Motor and driving system | Leadshine 1500w bus servo motor drive+Japan SHIMPO reducer |

| Transmission | X,Y axis: Taiwan helical rack Z axis: Taiwan TBI ball screw |

| Guide rail | Taiwan square rail: Y 30 XZ 25 |

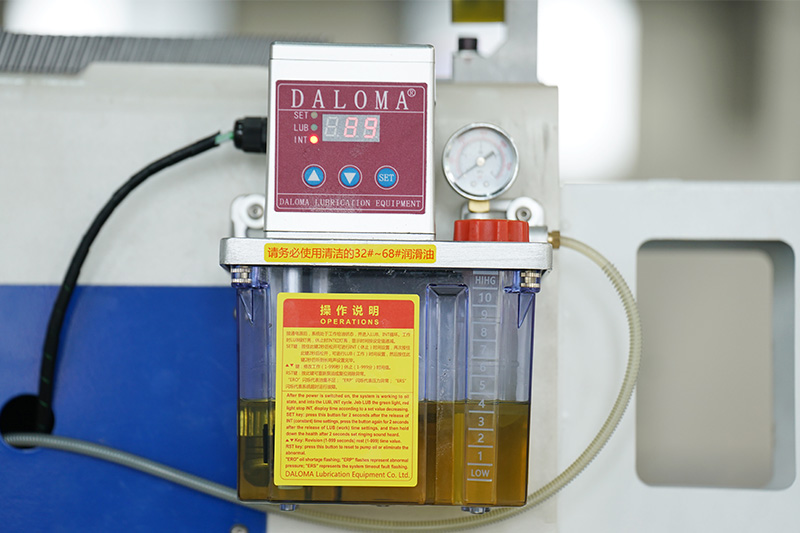

| Lubrication system | Automatic lubrication system |

| Vacuum pump | 7.5 kw Vacuum pump |

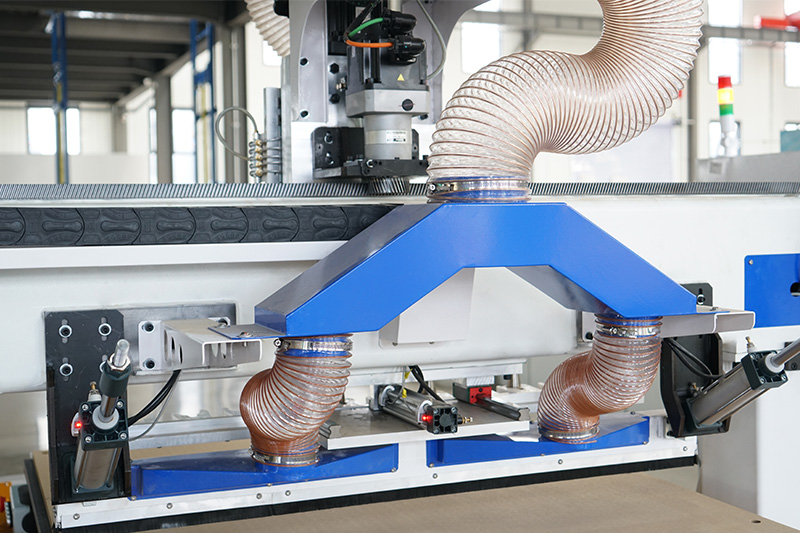

| Vacuum cleaner | 5.5kw Double bag vacuum cleaner |

| Tool calibration | Auto tool sensor |

Click for details

Auxiliary Feeding Wheel

Lubrication

Secondary Dust Removal Device

Tool Sensor

Click for solution

Click for quotation