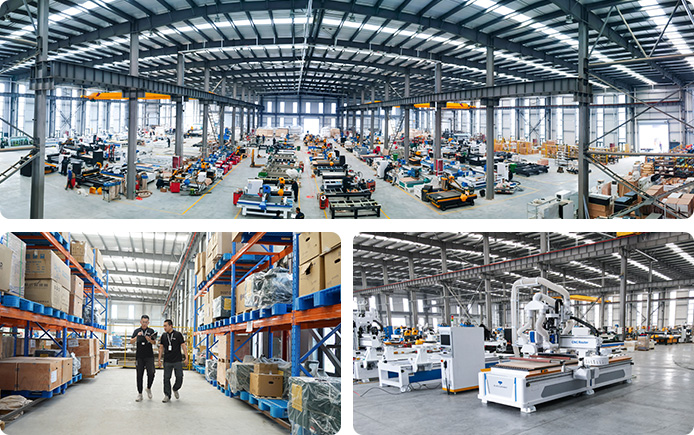

Double Heads EK2-1328 Linear ATC Nesting CNC Router

New Look 1328 ATC CNC Machining Center Nesting CNC Router

The dual-head Linear CNC machining center adds a set of 9KW tool-changing spindle heads to the traditional nesting CNC machine. The two spindles work at the same time, achieving the advantages of high efficiency, high speed and high precision.

1.The double-head woodcutting machine has built-in CAM software. When the conditions for double-head working are met, it can punch holes and cut materials at the same time, which improves the processing efficiency by 20-40% and shortens the production cycle;

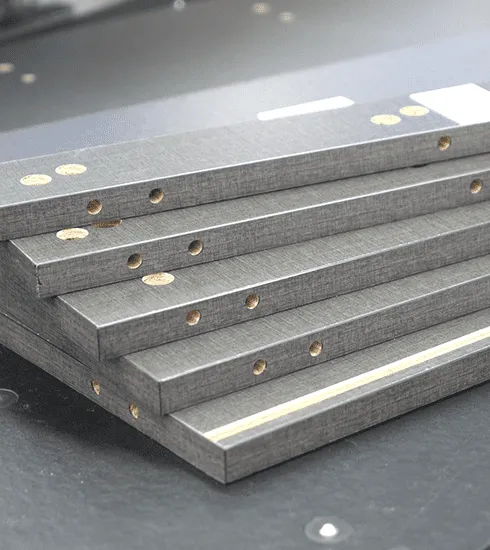

2.Two sets of 9KW high-power spindles are equipped with 12-position linear tool magazines (each spindle can be equipped with 6 tools), high-speed cutting, reasonable distribution of tool magazines, and no interference with each other;

3.This nesting CNC machine supports simple board patching function, you can complete the board patching work by entering the size (only for Delta software);

4.It supports tool life management (Delta software only);

5.It supports tool break detection function (Delta software only);

6.It supports most order splitting software on the market, easy and fast docking

7.Equipped with a double roller device, the distance between the double rollers is reduced to avoid board running;

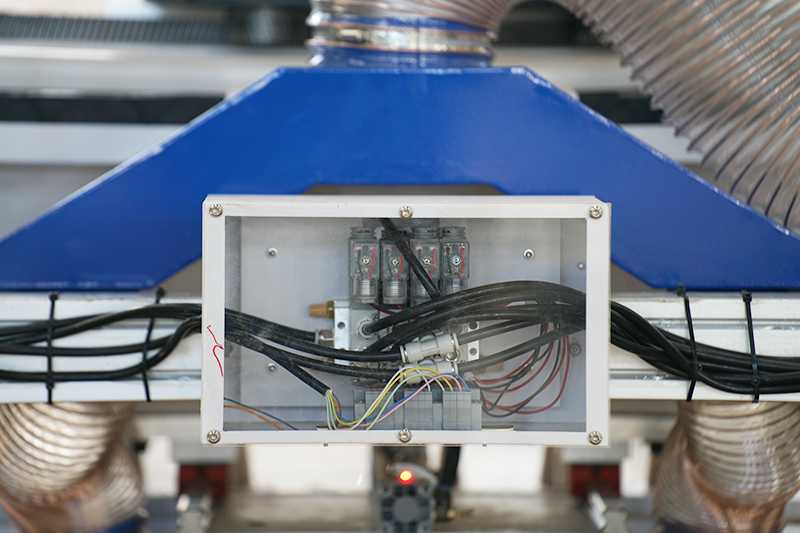

8.A safety anti-collision device is installed between the double heads to ensure safe operation;

9.The double heads have a compact structure, and the parts are easy to disassemble, which is convenient for maintenance and reduces maintenance costs.

| Model | EK2-1328 Double Head Linear CNC Machining Center with Auto Loading&Unloading |

| Working area(X-Y-Z) | 1300*2800*200mm |

| Table structure | Vacuum work table(7 Divisions) |

| Control system | Delta NC50E-WE dual channel and dual head, CAM software |

| Reducer | Japan Shimpo |

| Spindle type | 9kw JST air-cooling automatic tool change spindle*2, 24000r/min |

| Inverter | Fuling inverter H1 Series-11kw |

| Motor and driving system | Delta 850W bus absolute value |

| Guide rail | Taiwan SHAC square rail: Y 30 XZ 25 |

| Lubrication system | Automatic lubrication system |

| Vacuum pump | DN65 interface, 11kw water circulation vacuum pump 380V, 3ph, 50HZ |

| Positioning cylinder | 6 (Y4+X2) |

| Tool calibration | Fixed tool sensor |

| Voltage/Frequency | 380V/3P/50HZ |

| Chassis (type, color) | Rittal |

| Rack/Module | PCRCH 2 module helical rack |

Click for details

Auxiliary Feeding Wheel

Control System

Feeding Suction Cup

Secondary Dust Removal Device

Click for solution

Click for quotation