Description

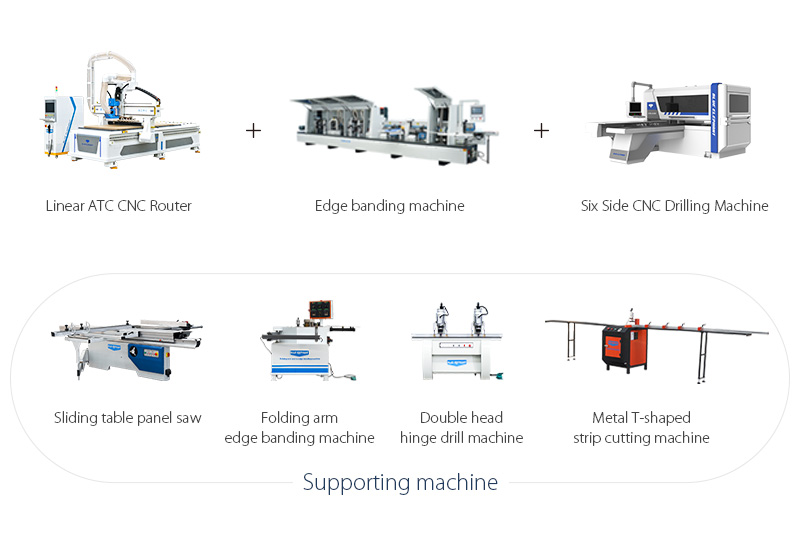

The high-end panel furniture production has three major equipments: a straight-line processing center, an edge bander and a six-sided drill. And it also includes other support equipments such as a precision saw, a stack-armed edge banding machine, a dual-spindle hinge drill, a metal strip cutting machine. It can meet the production and processing requirements of the house customized factory. It is flexible in machine combination and changeable in processing procedure. So it can meet the needs of the customer's entire factory as an automated production mode.

Features

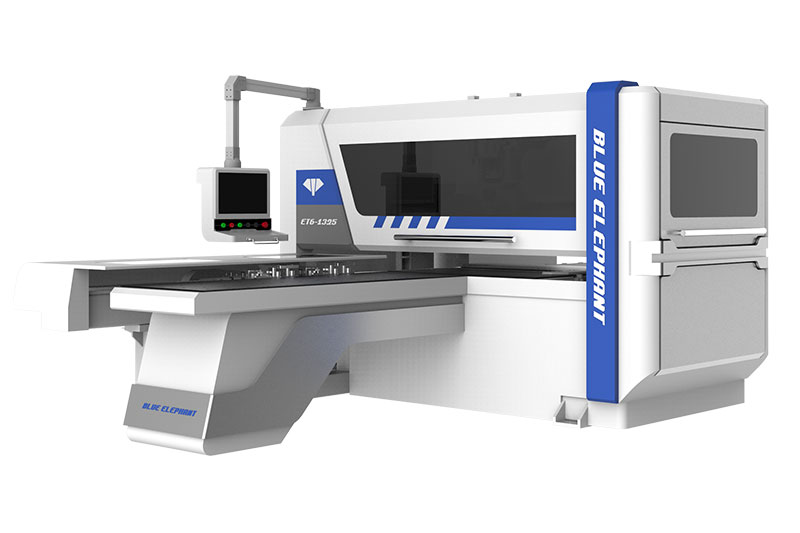

Linear ATC machining center

Introduction: The linear ATC machining center can engrave the furniture, wooden doors, cabinets, tables, chairs and other wood workpieces. It is equipped with an independent tool magazine. So it can change tools automatically in the course of processing without stopping the current work.

Features:

- It is suitable for complex and diversified production and processing work, such as drilling, cutting, side milling, beveling etc.

- All mechanical and electronic parts of this machining center adopt internationally famous brands.

- The automatic tool changer with 12 tools ensures fast tool changing and high efficiency.

- Strong software compatibility.

Automatic Edge banding machine

Main functions and procedure: Pre-milling to gluing welt 1-Six rounds pressing-baking lamp 1-Gluing welting 2-six rounds pressing-baking light 2-Front and rear trimming-finishing 1-Finishing 2-Tracking trimming- pneumatic edge scraping-flat scraping-pneumatic polishing 1-pneumatic polishing 2-screen one-button control front and rear cleaning.

Features:

- Scope of application: panel furniture, customized furniture, cabinet wardrobes, office furniture, solid wood furniture, tables, chairs, doors and windows, wood products, decoration and decoration industries, etc.

- Processable plates: MDF, ecological board, multi-layer board, particle board, flat solid wood board, aluminum honeycomb board and other boards.

Six Side drilling machine

The CNC six-sided drill can be directly connected with a variety of furniture design softwares. And it can process the six-sided (hinge hole, through hole, semi-through hole) and horizontal drawing groove.

Features:

- The system recognizes processing information by scanning the code, which is intelligent and efficient.

- Operated by computor, and also support CAD drawing, CAM import. You can directly import documents of open data formats such as DXF, MPR, xml, etc., which will make a convenient operation.

- It uses double clamping jaw guide rails to intelligently detect and avoid hole positions, reducing the time of changing hands during the drilling process. The clamping stroke exceeds 5.5 meters, which can capture and process large plates and shorten the hole processing time.

- It is equipped with air-floating workbench and air-floating pressure plate. The upper and lower surfaces of the plates form an air layer during the processing process. It improves the conveying efficiency of the plates and avoids scratching the plates. And the pressure plate is drilled at the same time to ensure the accuracy and efficiency of the drilling.

- The processing mode can be selected according to the production output and technology. And the next board can be processed after the board is processed without break.

Precision saw

Introduction: Precision saw is used for the longitudinal sectioning and cross-cutting work of various materials. It can process density fiberboard, ABS boards, PVC boards, PMMA, solid wood panels and other panels with similar hardness.

Features:

- European guiding rule can avoid displacement and ensure precision of panel cutting.

- Movable worktable is made of extruded aluminum alloy with high strength and no deformation.

- Extended and enhanced machine body ensures the machine stability during working.

Curved and straight edge banding machine

Introduction: The curved and straight edge banding machine is applicable for the banding work for straight and irregular edges of the panels.

Features:

- Flexible switching between curved and straight edge banding mode is allowed without interference and misoperation, which is accurate and convenient.

- With a limit switch, the machine can be shut down automatically.

- It is capable for processing such materials as: PVC, wood veneer, melamine, plastic etc.

Double-head hinge drill machine

Introduction: This machine is mainly applied to the boring of furniture door hinges. It can process cabinet doors, wardrobe doors, office and household furniture doors. In addition, it is able to adjust the boring position both longitudinally and horizontally to meet boring requirements quickly and easily.

Features:

- The drill package design ensures small noise and durable use.

- A positioning baffle and an accurate scale are adopted, which can be adjusted based on work demands.

- Controlled by a foot switch, it is convenient and labor saving.

- Multiple functions, and it is adaptive to multiple types of drill heads.

Metal strip cutting machine

Introduction: The metal strip cutting machine is mainly designed for new Chinese style door panel inlay, and it can cut metal strips off directly or cut continuously without breaking.

Features:

- One-touch start button switch.

- Foot pressing mode without hand pressing.

- Automatic pressing and cutting function.

- Save time, labor and cost.

- Precision alloy saw blade adopts hardening process, ensuring long service life.

- The saw teeth are isosceles and right-angled, and can cut accurately without error, and the saw blade is easy to replace.

- The extended pallet is convenient for continuous cutting and can be folded and disassembled easily.