There are two parts. Firstly, measure the length of tool.Secondly, calculate the offset.

The steps are as follows.

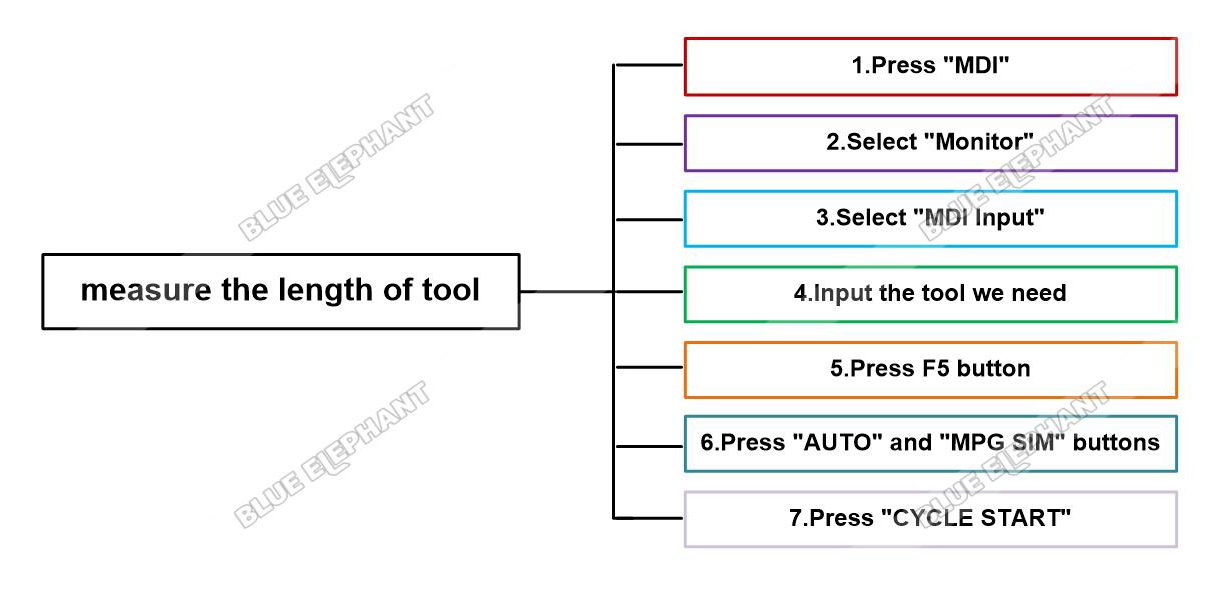

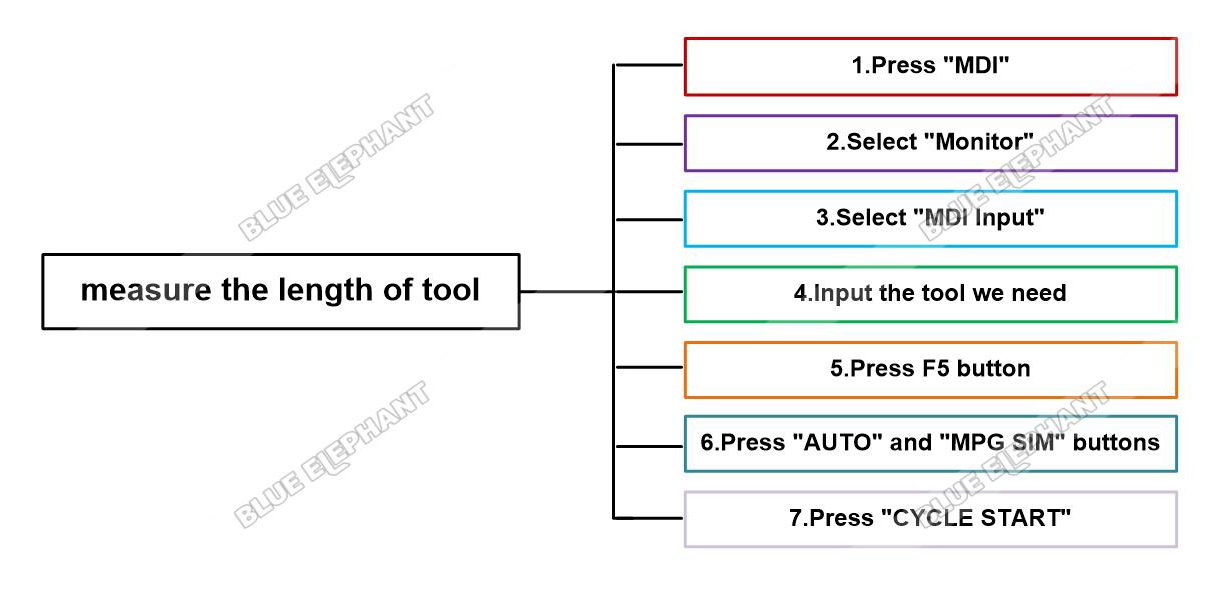

- The first part is measuring the length of tool.

-

- Press “MDI”,enter MDI mode

- Select “Monitor”

- Select “MDI Input”

- Clear the date and input the tool we need

for example,we need 3 tools.Then we can input T1,T2,T3

- Press F5 button in the control panel.The function of this button is to measure the length of tool.

- Press “AUTO” and “MPG SIM” buttons. The “MPG SIM”button is an optional choice.If you are very familiar with the machine and program,there is no need to open this function.

- Press “CYCLE START” to measure.

- Press F5 button in the control panel after measuring was done.

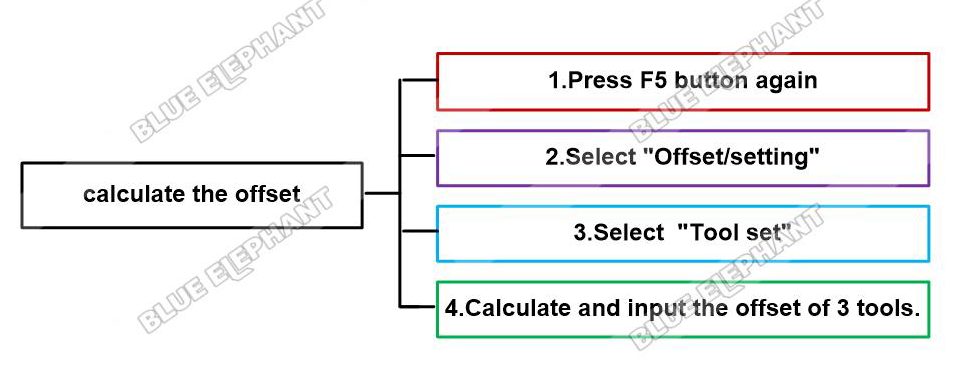

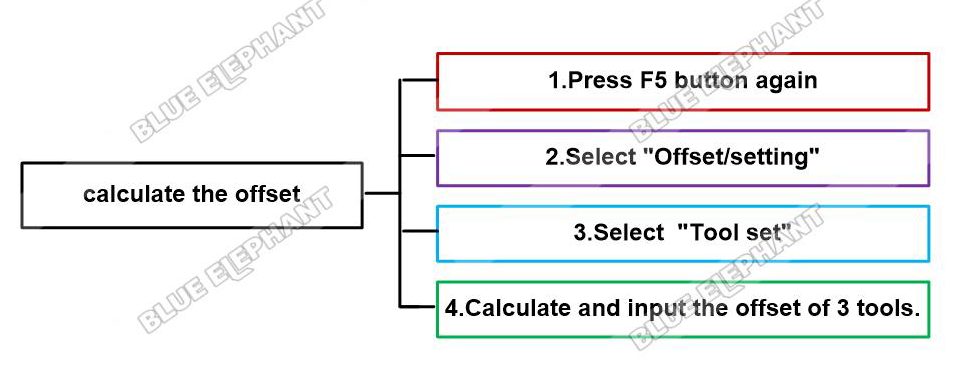

- The second part is calculating the offset.

-

- After measuring,press F5 button again to close the function.

- Back to maintain interface.Select “Offset/setting”

- Select “Tool set”

- Calculate and input the offset of 3 tools.

- 4.1) If we use T1 to set the workpiece zero point,we need take value of T1 as standard reference.

- The Length(H) of T1 is “T1-T1”,

- The Length(H) of T2 is “T2-T1”,

- The Length(H) of T3 is “T3-T1”.

- (Be careful of the symbol.)

- 4.2) If we use T2 to set the workpiece zero point,we need take value of T2 as standard reference.

- The Length(H) of T1 is “T1-T2”,

- The Length(H) of T2 is “T2-T2”,

- The Length(H) of T3 is “T3-T2”.

- (Be careful of the symbol.)

- 4.3) If we use T3 to set the workpiece zero point,we need take value of T3 as standard reference.

- The same method as above.

- The video is as follow.