Air Compressor Introduction and Application for CNC Router Machine

The air compressor for CNC router machine is an important device used to compress gas. The reciprocating piston air compressor relies on the piston to reciprocate in the cylinder to reduce the volume and increase the gas pressure.

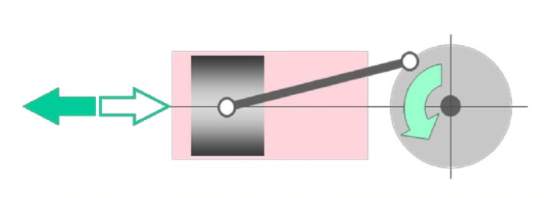

The reciprocating piston compressor converts the rotary motion of the crankshaft into the reciprocating motion of the piston through the crankshaft connecting rod mechanism.

When the crankshaft rotates, through the transmission of the connecting rod, the driving piston will reciprocate, and the working volume formed by the inner wall of the cylinder, the cylinder head and the top surface of the piston will change periodically. The crankshaft rotates once, the piston reciprocates once, and the process of air intake, compression, and exhaust is realized in the cylinder, which completes a working cycle.

Compared with other types of compressors, reciprocating compressors have the following characteristics:

1 The pressure range is wide, from low to high pressure are applicable;

2 High thermal efficiency;

3 Strong adaptability, the exhaust volume can be adjusted in a larger range.

Air Compressor Powered: Manual Oil Mist Cooling

Air Compressor Powered: Automatic Oil Mist Cooling

Air Compressor Powered: Automatic Tool Change, Tool Magazine Ejection, Spindle Mask Up and Down

Air Compressor Powered: Automatic Tool Change, Oil Mist Cooling, Dust Cover Up and Down

Air Compressor Powered: Plate Side Pushing and Back Pushing in Loading Process

Air Compressor Powered: Plate Pushing

Air Compressor Powered: Positioning Cylinder

Air Compressor Powered: Plate Pushing in Unloading Process

Connect Air Compressor to The CNC Router Machine

Connect Air Compressor to The Blowing Gun.

Pneumatic Pressure Reducer and filter