Some newcomers to the laser industry often ask questions: Can I make money with a

fiber laser marking machine? How can I make money with a fiber laser marking machine? Fiber laser marking machines are widely used in our lives, such as electronic communications, aerospace, auto parts, food packaging, etc., so the answer is yes.

In this article, we will have a comprehensive understanding of fiber laser marking machines and how we can make money with fiber laser marking machines.

Ⅰ.What is Fiber Laser Marking Machine?

Fiber laser marking machine is a device that uses fiber laser to generate high energy density laser beam and accurately marks or engraves the surface of workpiece through high-speed scanning galvanometer. Its working principle is to focus the laser beam generated by fiber laser on the surface of workpiece, so that the surface material evaporates or reacts chemically instantly to form a permanent mark. These marks can be text, graphics, barcodes, QR codes, etc.

Ⅱ.Advantages of Fiber Laser Marker

Traditional marking methods are time-consuming and labor-intensive, and have gradually been eliminated by the market. The use of fiber laser marking machines makes up for the shortcomings of traditional marking methods and has excellent performance in processing accuracy, processing speed, durability and maintenance costs.

The following are some advantages of fiber laser marking machines:

High precision: The spot of fiber laser marking machine is very small, usually at the micron level, which can achieve very fine marking and is suitable for marking complex graphics or small text.

High speed: Due to the high-speed scanning capability of fiber laser, fiber laser marking machine can complete marking tasks in a short time and improve production efficiency.

Durability and low maintenance: Fiber laser has a long service life, usually more than 100,000 hours, and does not require frequent maintenance, and has low cost of use.

Wide range of applicable materials: Fiber laser marking machine is suitable for a variety of materials, especially metal materials such as stainless steel, aluminum, copper, gold, silver, etc., and can also be used for some non-metallic materials such as plastics, ceramics, glass, etc.

No consumables: Compared with traditional marking methods, fiber laser marking machine does not require ink or other consumables, is environmentally friendly during use, and has low operating costs.

Flexible and diverse marking methods: The fiber laser marking machine can realize a variety of marking methods, such as dot marking, line marking, surface marking, etc., which can meet the needs of different application scenarios.

In addition, by adjusting the laser parameters, different marking depths and marking effects can be achieved, such as shallow engraving, deep engraving, shadow engraving, etc.

Non-contact processing: The fiber laser marking machine adopts non-contact processing. The laser beam acts on the material surface after focusing, and will not exert mechanical pressure or generate mechanical stress on the material. Therefore, the material surface will not be deformed or damaged, which is particularly suitable for processing precision parts and fragile materials.

Significant long-term cost benefits:Although the initial investment of fiber laser marking machines is higher, due to its low maintenance costs, no consumable costs, and efficient production capabilities, fiber laser marking machines are significantly cost-effective in the long term.

Its durability and high productivity mean users can recoup their equipment investment in a shorter period of time and achieve higher profit margins through reduced operating costs.

Ⅲ.The Difference Between Fiber Laser Marker, CO2 Laser Marker and UV Laser Marker

Many newcomers often see the words fiber laser marking machine,

CO2 laser marking machine, and

UV laser marking machine appear at the same time when collecting information. They have different application fields and technical characteristics.

The following is a summary of their differences.

| Feature |

Fiber Laser Marker |

CO2 Laser Marker |

UV Laser Marker |

| Laser Wavelength |

1064 nm |

10.6 µm |

355 nm |

| Applicable Materials |

Metals, plastics, ceramics, PCBs, circuit boards, etc. |

Non-metallic materials like wood, plastics, paper, glass, leather, etc. |

Fine materials like glass, polymers, plastics, etc. |

| Marking Effect |

High contrast, fine marking, deep engraving |

Suitable for large area marking, fast speed |

High precision, no thermal effect, non-damaging marking |

| Marking Speed |

Fast |

Relatively fast |

Relatively slow |

| Heat-Affected Zone |

Small |

Large |

Very small |

| Typical Applications |

Marking metal parts, plastic product numbering, electronic components |

Packaging, labels, clothing, leather goods, wooden products |

Fine marking of electronics, precision instruments, medical devices |

| Advantages |

Durable, low maintenance, high efficiency |

Effective on non-metal materials, lower cost |

Precise, non-damaging marking, suitable for special materials |

| Disadvantages |

Not suitable for some non-metal materials |

Not suitable for metal marking |

Higher cost, lower power |

| Cost |

Moderate |

Relatively low |

Relatively high |

Ⅳ.10 Ways to Make Money with Fiber Laser Marking Machines

Fiber laser marking machines have the advantages of high precision, high speed, non-contact processing, and are suitable for marking a variety of materials and complex patterns. We can use fiber laser marking machines to make money in multiple fields.

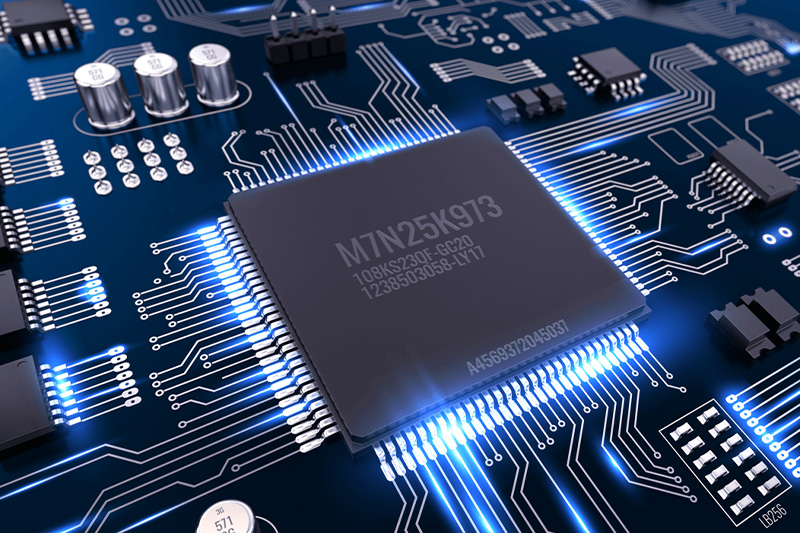

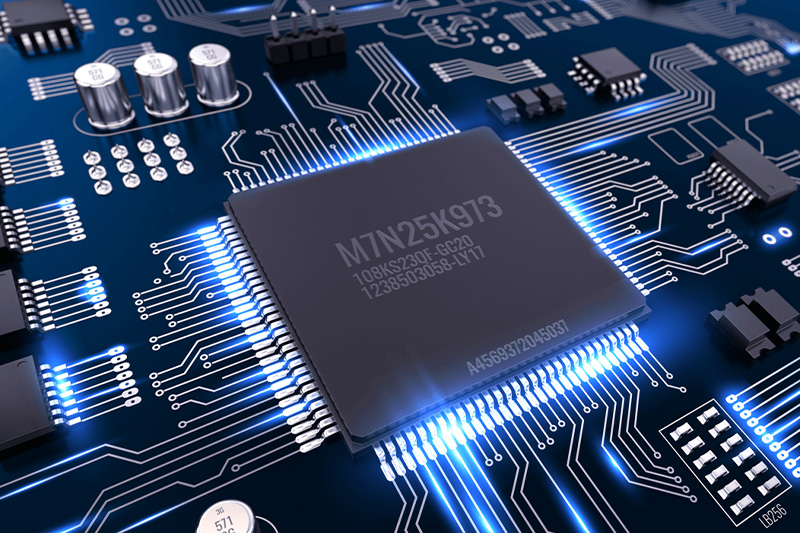

1. Electronics and electrical industry

The electronics and electrical industry is one of the core areas of application of fiber laser marking machines. In the manufacturing process of electronic components, micro devices such as integrated circuits (ICs), capacitors, resistors, etc. require extremely high precision and clarity. Fiber laser marking machines can perform high-density marking on a very small surface area, ensuring the identification and quality traceability of components.

The marking content usually includes product model, specifications, production date, and brand logo. In addition, household appliances such as refrigerators, televisions, washing machines, etc. also need to mark product serial numbers, qualified marks, and brand logos during the production process.

2. Automobile manufacturing industry

Automobile manufacturing is another important application field, and fiber laser marking machines are widely used for marking automobile parts. Automobile parts such as engines, chassis, gearboxes, etc. need to be marked with numbers, production dates, manufacturer information, and anti-counterfeiting logos.

The fiber laser marking machine has strong durability, wear resistance, and high temperature resistance, so that the marking can remain clear for a long time in harsh working environments, thereby improving the reliability and safety of automobile parts.

3. Medical device industry

In the medical device industry, fiber laser marking machines have extremely high application value. The contents that need to be marked on medical devices usually include the name of the device, production batch number, instructions for use, company logo, etc. These markings are essential for the quality control, safety of use, and compliance with laws and regulations of medical devices.

Fiber laser marking machines are pollution-free and loss-free during the marking process, meeting the strict requirements of the medical industry. For example, on surgical instruments, laser marking can not only ensure the clarity and durability of the marking, but also avoid medical accidents caused by the falling off of the marking.

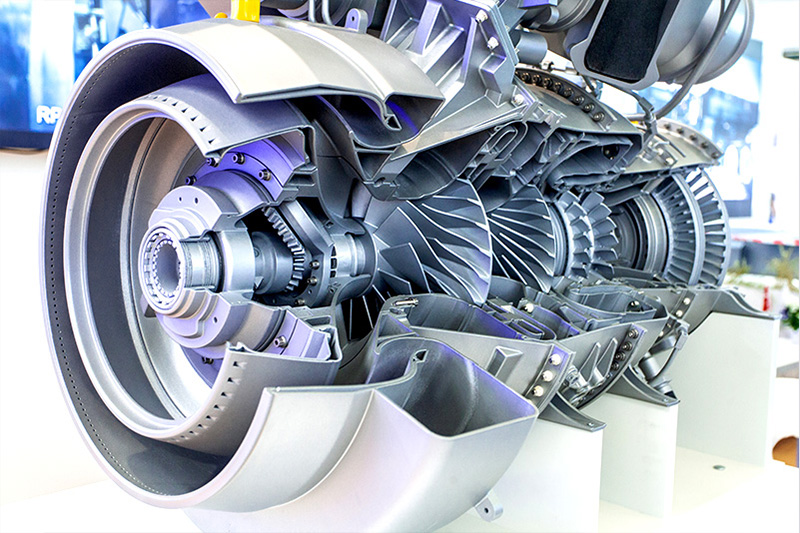

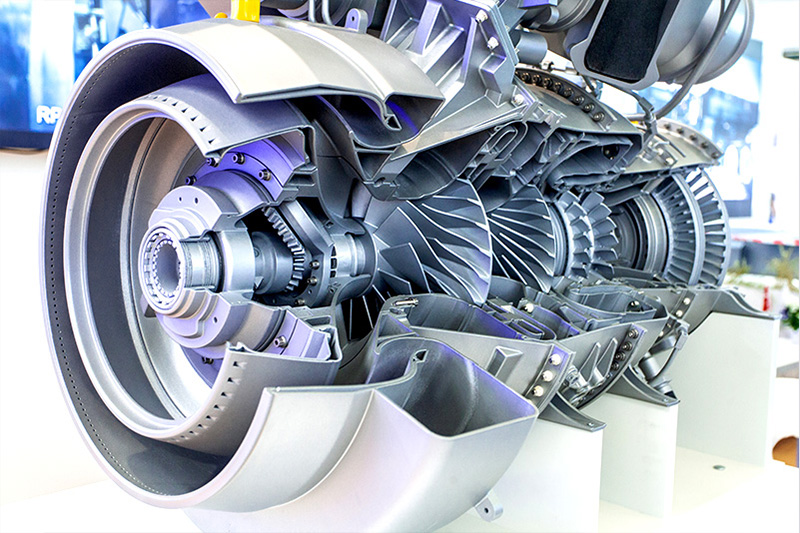

4. Aerospace Industry

The aerospace industry has extremely high requirements for product quality and reliability. The marking of any component must be clear, durable and highly resistant to environmental stress. The application of fiber laser marking machines in this field includes the marking of key components such as aircraft engine parts, wings, turbine blades, and instrument panels. Fiber laser marking machines can make accurate and durable marks on these materials.

5. Consumer electronics industry

In the field of consumer electronics, fiber laser marking machines have become the main tool for brand identification and product information marking. The shells of electronic products such as smartphones, tablets, and laptops usually need to be marked with brand logos, models, serial numbers, and other information. Fiber laser marking machines can make high-precision and high-definition marks on the shells of metals, plastics, and other materials, and the marking speed is fast, which can meet the needs of mass production.

6. Jewelry and crafts industry

The jewelry and crafts industry has extremely high requirements for the accuracy and artistry of marking. Fiber laser marking machines are widely used in this field because they can perform high-precision and non-destructive marking on precious metals such as gold, silver, platinum, palladium, and materials such as gemstones. For example, personalized markings such as engraving, date, and pattern are performed on jewelry such as rings, bracelets, and necklaces.

Fiber laser marking can provide extremely exquisite and durable effects. Non-contact processing can avoid the damage to precious metals caused by traditional engraving methods and maintain the original luster and quality of jewelry.

7. Food and pharmaceutical packaging industry

The requirements for marking in the food and pharmaceutical packaging industry include not only anti-counterfeiting and traceability, but also information transparency and security. Fiber laser marking machines are widely used for information marking on food and pharmaceutical packaging, such as production date, shelf life, batch number, manufacturer information, etc.

Compared with traditional ink jet coding, fiber laser marking has higher clarity and durability, and can maintain the integrity of information during the transportation and storage of packaging. In addition, laser marking does not use any chemicals and meets the hygiene requirements of the food and pharmaceutical industry.

8. Tools and equipment industry

Products in the tools and equipment industry usually need to be marked with information such as model, brand, instructions for use, technical parameters, etc. on the surface of hard materials. The marks made by fiber laser marking are extremely wear-resistant and corrosion-resistant, and can remain clear during the long-term use of tools and equipment. For example, on hardware tools such as wrenches, screwdrivers, pliers and other products, fiber laser marking machines can achieve accurate model markings to help users quickly identify and select.

9. Energy industry

The energy industry involves multiple fields such as electricity, oil, natural gas, and solar energy. The equipment and components in these industries usually need to be marked with key information such as technical parameters, production dates, and warning signs. The application of fiber laser marking machines in the energy industry includes the marking of equipment such as batteries, cables, solar panels, and pipelines. For example, when marking the production date and model on the battery, the fiber laser marking machine can ensure the clarity and durability of the mark, and maintain the integrity of the information even in harsh environments such as high temperature and high humidity.

10. Clothing and textile industry

Fiber laser marking machines can also be used in the clothing and textile industry, mainly for marking clothing tags, leather products, etc. On clothing tags, fiber laser marking can achieve fast and efficient marking, ensuring the accuracy and clarity of information. In addition, laser marking machines are also widely used in leather products, such as leather shoes, bags, belts, etc., for exquisite marking of trademarks, patterns and texts.

Ⅴ.Improve Your Ability to Make Money with Fiber Laser Marking Machines

1.Choose the right fiber laser marking machine manufacturer

When purchasing a fiber laser marking machine, it is crucial to choose a suitable manufacturer.

First of all, a strong manufacturer is able to provide high-precision and high-stability marking machines to ensure the clarity and durability of product identification. Secondly, reliable manufacturers usually have a complete after-sales service system. In addition, well-known manufacturers usually use high-quality materials and advanced processes to manufacture equipment. Finally, choosing a manufacturer with a good market reputation and credibility can reduce the risk of purchase and ensure that the purchased equipment meets the expected standards.

Blue Elephant is a good choice. All machines are independently developed and produced, and have undergone strict quality control. It has complete after-sales service, has obtained many technical patents, and has won unanimous praise from domestic and foreign customers.

2.Choose the Right Fiber Laser Marking Machine

The following fiber laser marking machine adopts desktop marking, takes up less space, and can process a variety of metal and non-metal materials. It is an ideal machine for laser marking.

3.Develop the right business positioning

After you have a good machine, you need to position it in the market correctly.Conduct market research, understand local market demand, and determine target customer groups. After analyzing the local user groups, you can choose to invest in any of the 10 ways to make money introduced above, but it must meet local needs.

If the local heavy industry is developed, then you can choose to invest in marking auto parts, etc. If the local business is prosperous, you can also choose to invest in the clothing and textile industries. In short, you must do a good job of research.

4.Ensure the quality of marked products

Only by ensuring good marking quality can you gain the trust of customers, get a large number of returning customers, and gain a good reputation. In this way, your laser marking business will last long.

5.Do a good job in marketing promotion

You can use various online and offline channels for marketing promotion. For example, online channels can use Facebook, Instagram, Twitter, WeChat and other platforms for content promotion and advertising. You can also create valuable content such as blogs, videos, white papers, etc. to attract and educate potential customers. Offline channels can attract customers through in-store activities, discounts, member-only offers, etc.

Ⅵ.Conclusion

Using fiber laser marking machines to make money is a very good choice. With the continuous advancement of technology and the expansion of application scenarios, the application field of fiber laser marking machines will be further expanded, providing more advanced and efficient marking solutions for all walks of life.

If you have any questions, please feel free to consult Blue Elephant:

https://www.elephant-cnc.com/ https://www.cncrouter-shop.com/Email: manager@elephant-cnc.com

Whatsapp/mobile: +86-15064026772