CNC router kits are the most indispensable parts of the CNC router machine. A high-quality CNC router kit can build the best CNC machine. Moreover, it will complete excellent product processing. So what is the CNC router kit? How should we choose the CNC router kit? Can we customize our own machine with the CNC router kit?

The following content will make a complete introduction of Blue Elephant CNC router kits, including core CNC router kits and optional CNC router kits. Here is the main points. Hope to give you some help.

| Core CNC router kits |

Spindle |

| Table |

| Controller |

| Rail |

| Motor |

| Optional CNC router kits |

Tool changer magazine |

| Rotary device |

| Reducer |

| Lubrication system |

| Spray system |

| Reducer |

| Aggregate head |

| Oscillating knife |

| Pop up pin |

| CCD camera |

| Pump |

Core CNC Router Kit

1. Spindle

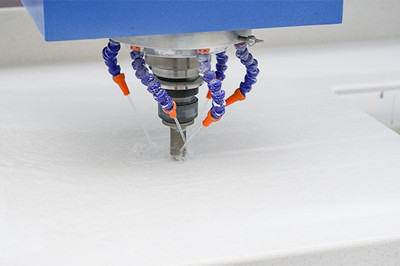

What is a spindle on a wood CNC router? A spindle is a shaft in a mechanical transmission device that receives power from an engine or electric motor and transmits it to other parts. According to different types of machines, spindles are also divided into various types.

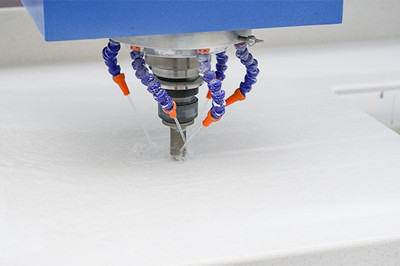

First of all, spindles are generally divided into two types: air cooling spindles and water cooling spindles. What is a water cooling spindle? The water cooling spindle uses water circulation to cool the heat generated by the high-speed rotation of the spindle. While the air cooling spindle uses a fan to dissipate heat.

Once the spindle heats up, it will affect the normal operation of the equipment. Therefore, we need to "cool down" the spindle. The cooling methods include air cooling and water cooling. Through these two methods, the temperature of the continuously heating spindle can be lowered, and the normal operation of the equipment can be ensured.

Which CNC router kit is better, air cooling spindle or water cooling spindle?

1. Noise: The water cooling spindle basically has no noise, while the air cooling spindle is noisy.

2. Life: water cooling spindle needs more attention to maintenance, and it is more frequent to replace circulating water, so it has a much longer life service than the air cooling spindle.

2. Accuracy: The axial and radial accuracy of the water cooling spindle motor is basically below 0.003 mm, which is not as good as the air cooling spindle.

4. Convenience: The water cooling spindle needs to be connected to the water pump. As a result, it is easy to freeze in the cold winter. And some customers may find it more troublesome. However, the air cooling spindle will not have such a problem. In addition, the circulating water does not need to be replaced frequently, and the maintenance cost is low.

5. Effect: After cooling down, the temperature of the water cooling spindle will not exceed 40 degrees. While the cooling effect of the air cooling spindle is not as good as the water cooling spindle.

| Items |

Water cooling spindle |

Air cooling spindle |

| Pictures |

|

|

| Advantages |

- Low noise

- Better cooling effect

- Longer life service

|

- Easy use

- Low maintenance cost

- Less environmental affected

|

| Disadvantages |

- High maintenance cost

- Easily affected by the environment

|

- Higher price

- Louder noise

|

From the above five points, the air cooling spindle and the water cooling spindle have their own advantages and disadvantages. If you want a good cooling effect, then the water cooling spindle is recommended. If you want more convenience, you’d better choose an air cooling spindle. For countries with higher quality requirements, I suggested they use the Italian HSD air cooling spindle, which has after-sales service around the world. With it, you can have better guarantees.

Secondly, according to the power, there are many types of spindle power to choose from. The commonly used ones are 3kw, 5kw, 5.5kw, 6kw, 7kw, 9kw, and even greater power. Commonly used spindle brands are Italy HSD, Changsheng, HQD, etc.

2. Working table

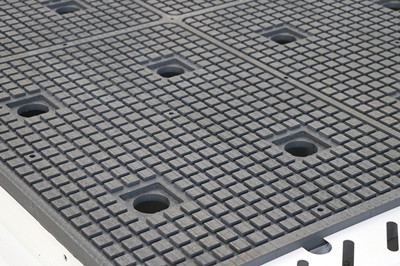

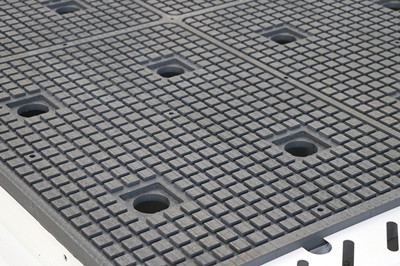

There are roughly three types of worktables: Full vacuum working table, T-slot&vacuum working table, and aluminum T-slot working table. How do we choose the right processing table?

| Vacuum working table |

- Time-saving, strong, but a high price

- Suitable for the production of wooden doors, cabinets, and other furniture

|

|

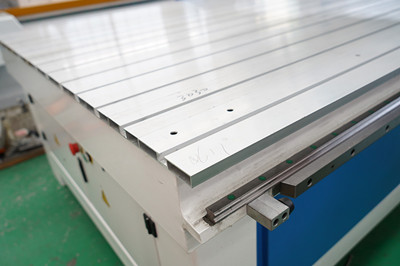

| Aluminum T-slot working table |

- Not convenient, but low cost

- Suitable for processing hollow or profiled materials

|

|

First, the vacuum working table saves processing time and greatly improves the working efficiency. The aluminum worktable needs to manually fix or use a fixture to fix the processing material, which is cumbersome to use. While the full vacuum working table can automatically fix the processing material.

Second, the vacuum working table is much stronger. It can be divided into four sections, six sections, and eight sections. which can greatly enhance the adsorption, so it has a stronger fixation.

Third, the price of a full vacuum working table is higher. The woodworking engraving machine with a vacuum working table has a vacuum pump and a rubber table, which increases the whole cost. Besides, the power of the spindle motor also increases, so the price is much more expensive.

Fourth, the application range is not very common. The full vacuum working table is suitable for wooden door processing and large-scale plate relief carving. For hollow processing and uneven carving workpieces, it is more suitable to use an aluminum table.

Although the vacuum working table can save a lot of time, it is not suitable for every user to process. When choosing an engraving machine table, you must choose a suitable one according to your own processing technology.

3. Controller

The control system is the most important CNC router kit for CNC machines, which is equivalent to the human brain. The main function of the control system is to execute the instructions of the computer software to control the work of the inverter and the drive. Commonly used control systems for woodworking engraving machines include handling control systems and computer control systems.

The handling controller does not need to be connected to a computer, which can save a lot of floor space. In addition, it has a simple operation. So it is easier to learn and master. After power off and restart, the machine has an automatic engraving function, eliminating the cumbersome manual point-pointing and improving work efficiency. The failure rate is lower and the machine runs more smoothly.

The computer control method can not only preview the processing effect but also watch the processing track at any time. It is beneficial for you to correct the program loading error during the operation in time. All functions are displayed on the control panel, and the operation is very convenient.

Blue Elephant adopts internationally renowned brands of systems, such as the Mach 3 controller, Syntec controller, DSP control system, Siemens control system, Taiwan LNC controller, etc.

1. DSP handheld control can control your CNC router without connecting to a computer. Besides, it is a cheap CNC router kit with low price.

2. NC controller is based on Windows 8 or Windows 10 operating system. It can control your CNC router through a computer.

3. Syntec/Siemens controller is an independent control system that can control complex machining paths. It is very suitable for large-scale CNC engraving machines with servo motors.

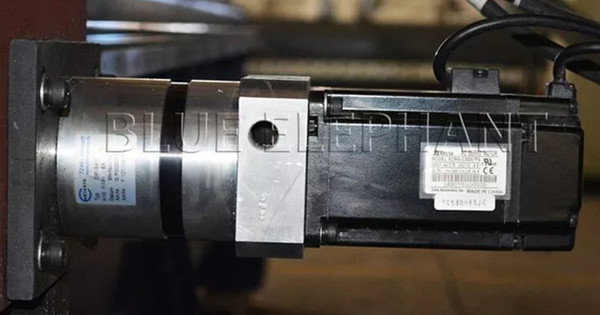

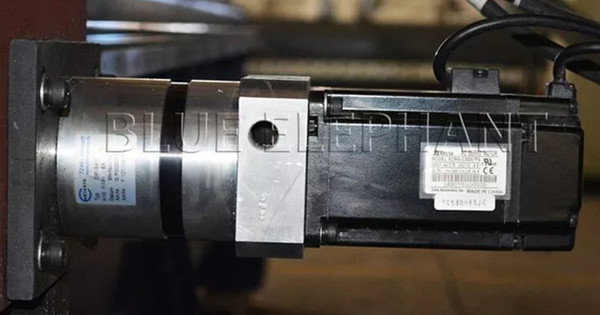

4. Motor

Commonly used motor brands: Japanese YASKAWA, Taiwan Delta, and Leadshine.

According to the type of working power supply, it can be divided into DC motors and AC motors. Among them, AC motors can also be divided into single-phase motors and three-phase motors. And according to the purpose, it can be divided into drive motors and control motors. Further subdivided, control motors are divided into stepper motors and servo motors.

The differences between stepper motors and servo motors are mainly in the control mode, working process, low-frequency characteristics, torque, and overload capacity. The price of stepping motors is lower than that of servo motors. Therefore, the stepper motor is a kind of cheap CNC router kit. Most CNC routers use stepper motors, but for advanced models, such as ATC and 4-axis CNC routers, it is best to choose a servo motor. In addition, if you do not want to use a stepper motor, but have a limited budget, you can choose a hybrid servo motor. Stepper motors can mix with servo or stepper drivers, while servo motors can only use matching servo drivers.

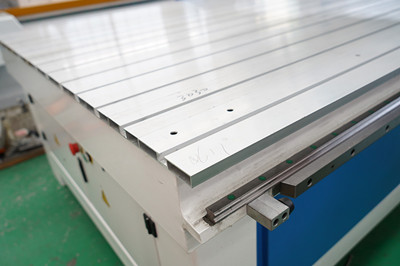

5. Rail

Guide rail is a CNC router kit that hold, guide, and reduce the friction of CNC mobile equipment. It includes round rails and square rails.

Linear slide guide has low cost, short production cycle, easy installation, and is suitable for small-format precision carving. So it is the best choice for small CNC routers or desktop CNC woodworking machines. While the linear guide rail has the advantages of strong bearing capacity, stable operation, low friction resistance, high positioning accuracy, etc. It is suitable for large-format precision engraving. It is an ideal CNC router kit for stone CNC carving machines, woodworking engraving machines, foam engraving machines, etc.

Optional CNC Router Kit

1. Inverter

Generally, the power of the inverter is greater than the power of the spindle. And its main function is to adjust the speed and reduce the starting current. Commonly used inverters include Fuling inverter and Delta inverter. Fuling inverter has the features of stable performance, rich function combination, good dynamic characteristics, and super overload capacity. While Delta inverter has the advantages of small size, good control performance, good compatibility, and strong versatility.

2. Automatic tool changer magazine

The automatic tool changer is abbreviated as ATC, which is an important CNC router kit of the machining center. It can automatically change the tools and increase the production capacity. The automatic tool changer can quickly change the tools, reducing non-running time. At the same time, it can be designed with a variety of tools. Moreover, it can be used to replace worn or damaged tools, which can make the machine tool one step closer to the goal automation.

The automatic tool change system generally consists of a tool magazine and a manipulator. It has the characteristics of short tool change time, high tool repeats positioning accuracy and sufficient tool storage. CNC machines often use carousel tool magazines and linear tool magazines. The carousel tool magazine is mainly used on vertical processing machines, which can accommodate 30 tools, and the tool change speed is accurate and fast. When the carousel is changed, the tool magazine rotates to the tool change position for tool change. The linear tool changer is placed in a straight row. When the tool is changed, the head moves to the tool-changing position for replacement. Generally, the speed of the linear tool changer is faster than that of the carousel-type tool changer because it does not need to rotate the tool magazine.

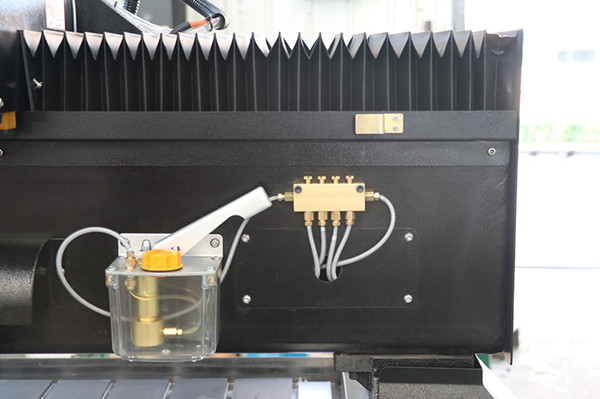

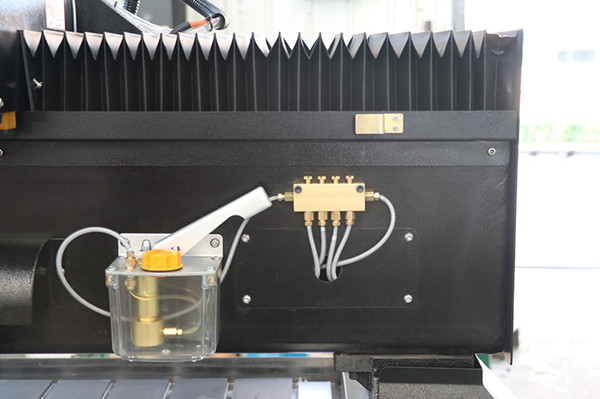

3. Lubrication system

The lubrication system is divided into a manual lubrication system and an automatic lubrication system.

The manual lubrication system has the advantages of small size, easy installation, and convenient use. In addition, there is also a non-reverse flow device, which can effectively avoid the phenomenon of oil backflow.

The automatic lubrication system adopts centralized control to automatically realize the lubrication effect. It can be lubricated regularly and quantitatively, which has the advantages of energy-saving and oil-saving. In addition, this lubrication method can effectively reduce wear and tear, thereby extending the service life of the machine.

4. Rotary device

The rotary device is a necessary 3 axis CNC kit, especially for the rotary CNC machine. It can help you achieve wood 3D engraving. It can be installed in any position according to customers' preferences and needs to meet their diverse needs. With this 3 axis CNC kit, the 3-axis CNC machine is equivalent to another kind of 4-axis CNC machine, which can process column objects from multiple angles, such as statues, stair armrests, table and chair legs, cylinders, sofas, stone statues, etc.

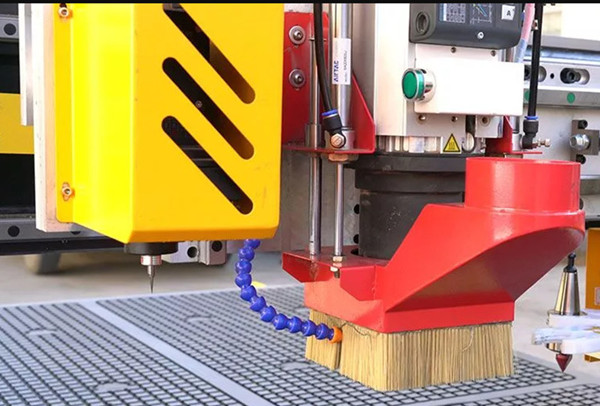

5. Aggregate head

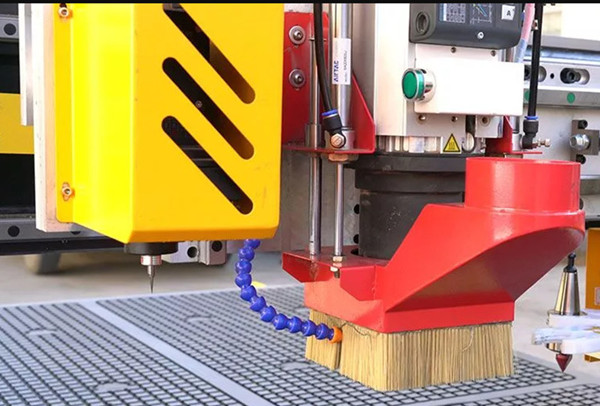

Aggregate head is mainly used to change the direction of the tool, which is suitable for users with side machining requirements.

6. Oscillating knife

The oscillating knife mainly used in cutting flexible materials such as cloth, silk loop, leather, felt, carpet, silicone, rubber, KT board, and so on.

7. Pop up pin

Pop up pin can make the position of the workpiece more accurate, to ensure better processing effect.

8. CCD camera

It can be equipped with CCD camera visual image positioning system to make positioning more intelligent and precise.

9. Pump

German Becker pump has the advantages of large suction, long service life and convenient after-sales service. It is usually used with the vacuum worktable for better fixation.

10. Reducer

Reducers have two main functions. One is to reduce speed while increasing output torque. Another is to reduce the inertia of the load while decelerating. So as to ensure the smooth operation of the machine and reduce machine damages.

Conclusion

CNC router kits are like human organs and bones. The most commonly used CNC router parts kit for three-axis, four-axis, ATC, and five-axis machines include spindles, motors, control systems, worktables, inverters, rotary devices, automatic tool changers, etc. Commonly used CNC router parts kits for laser machines include laser generators, laser heads, laser tubes, safety covers, etc.

Understanding CNC router kits can help you better produce high-quality and high-precision CNC machines. Choosing the right CNC router kits can not only better ensure the stable operation of the machine, but also improve the processing quality, cutting speed, and machining accuracy of the router.

When installing the CNC router parts kit, our staff will go through layers of checks and strict controls to ensure that every part is installed in the correct position, and every part is not damaged.

The above content is just a brief introduction. If you want to get more information about the CNC router kit, please consult us.