For many users, the service life of the stone CNC router has always been a concern. Because the service life of the CNC router directly affects the company’s benefits in terms of purchase cost and maintenance cost. In order to create greater value for the company or bring more profit to the company, then follow the Blue Elephant to learn how to extend the service life of the stone CNC router.

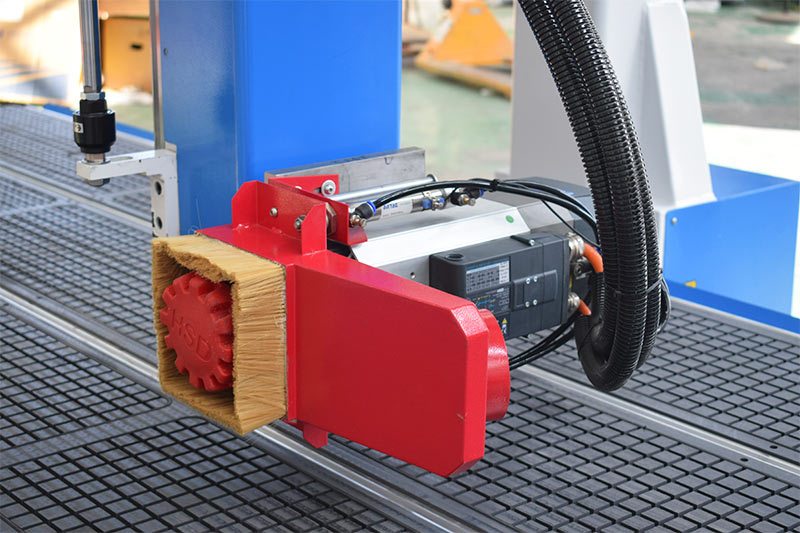

First of all, We need to do a good job of removing the dust from the working table and other parts of the engraving machine. Once the dust enters the inside of the device, it will affect the normal use of the device and affect the production efficiency. Therefore, it is necessary to do the cleaning work of the CNC router.

Secondly, it is necessary to do anti-rust work on the engraving machine. If some parts are aged or rusted, it will directly affect the normal operation of the machine, which will affect the processing quality and production efficiency of the machine. Especially for the transmission system of the machine, it is necessary to do the lubrication work of the engraving machine transmission device, and regularly apply the anti-rust oil to the equipment to avoid rusting.

We also pay attention to voltage issues. Long-term voltage instability can affect the engraving effect and shorten the life of the invert and spindle motor. Therefore, it is recommended that it is necessary to install the regulator if the voltage is not stable.

In addition, lubrication issues should also be taken seriously. When the guide rail is driving, the bearing capacity is relatively large. In order to ensure the normal operation of the guide rail, the lubricating oil is very important. Therefore, users are advised to ensure that each track enters the oil smoothly.

The problem of spindle cooling is not to be underestimated. We all know that the engraving machine will cause the spindle temperature to be too high under long working hours. In order to ensure that the spindle is not damaged, it is necessary to observe whether the circulating water outlet is blocked or the temperature is too high. If conditions permit, we can choose a water chiller to ensure the temperature of the circulating water.

The last thing to say is the choice of the tool. Especially when processing hard work pieces, tool selection is especially important. Long-term use of sharpness can have a large impact on the spindle and bearings. Therefore, it is necessary to replace the appropriate tool in time when machining different work pieces with the advice of a professional.

The above is the advice given by the professional engineers of Blue Elephant . If you want to know more about it, please continue to follow our blogs.