Many new users will face a problem that they do not know how to operate the CNC wood router. Because they are not familiar with the basic operation of the CNC router in the early stage, in order to avoid some unnecessary troubles in the operation, Blue Elephant will let you know the details of operating the CNC wood router. Here are five points to note for newbies.

1. Familiar with the materials that can be processed by engraving machines. These materials generally include acrylic, plexiglass, PVC, solid wood panels, marble, and two-color panels. In addition, operators must be familiar with the range of applications of various materials to decide what kind of engraving method to choose.

2. Familiar with the operation of the engraving machine programming software, mainly including the following requirements to quickly find the path error, various types of software layout, various operations, path generation. Depending on the user's processing area, the required programming software is not the same. So we must study the corresponding training manual on the machine.

3. Before using the engraving machine, we need to have a comprehensive understanding of the engraving rotary tools bit, distinguish the scope and function of the various tools, and unloading the tools and install the tools operation under the guidance.

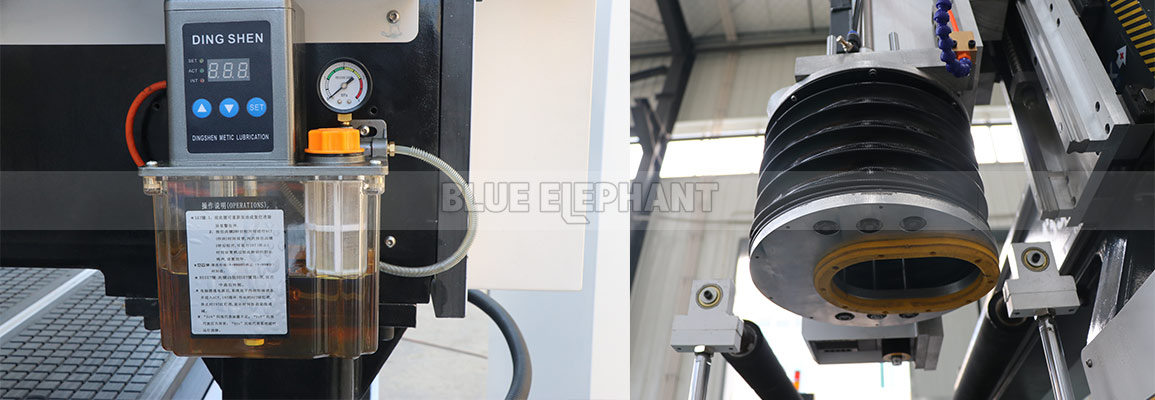

4. Master the basic knowledge of engraving machine, such as understanding the main functions of the engraving machine and the main functions of each part, as well as various working parameters of the engraving machine such as power, spindle speed, motor brand and so on. In addition, we need to understand some industry-specific terminology such as power-off continuation, hollowing, stenciling, and inscription.

5. Establish correct machine maintenance concepts and develop strict maintenance measures and regulations, to ensure that the machine is ready to work in the best possible condition. The following are the maintenance skills of the engraving machine.

If you are also a new user of the CNC router, please read this article carefully. If you have other questions about the machine, please contact us. We are always available to answer any questions you may have about the engraving machine.