What Are the Different Types of Edge Banding Machines?

1. Automatic edge banding machine

Fully automatic edge banding machine

We have 3 series automatic edge bander for sale. They are the E50 edge bander machine, the E60 edge bander, and the E70 edge bander for sale. Each kind of serise has different configurations, characteristics, and functions.

The E50 edge bander is the most entry-level and smallest fully auto edge banding machine for sale. While the E60 edgebander has the advantages of affordable price, multiple functions, and high accuracy. And the E70 edge banding machine is the most upgrade machine for edge banding. It has the most functions of pre-milling, gluing and banding, end cutting, rough trimming, fine trimming, tracking and rounding, scraping, cleaning, and polishing. Some of them are even equipped with glue pot to ensure a better banding effect.

Semi-automatic edge banding machine

The semi-auto equipment for edge banding is one of the most hot-sale edge banding equipment. Because it has an economical price but more functions. For example, it can realize multiple functions in only one machine, such as conveying, gluing, cutting, flushing, trimming, and polishing. It is suitable for the linear edge banding of solid wood board fibreboard and chipboards. Besides, it is safe for works at a controlled distance when operating the edge bander.

2. Manual edge banding machine

Different from the automatic edge banding machine. The manual edge bander needs to be operated by hand. Therefore, it is more simple to use with our learning operation process. And the manual edge bander can apply glue on both sides of the plate and the sealing tape. The glue is evenly applied, and the material is manually fed. It is suitable for straight curved edge banding of various sheets. Besides, it has the features of small size, light weight, low price, and wide application. So it is commonly used in furniture processing, cabinet processing, edge banding of interior decorative panels, etc.

How Do You Use the Edge Bander?

How to use the manual edge banding machine?

①Power on the control panel.

②Adjust the folding arm/ the support roller.

④Place the edge band on the turntable and pull the interface of the edge band into the edge bander.

⑤Adjust the temperature and turn on the foot switch.

⑥Bring the sheet to the edge banding station.

⑦Press the board tightly and hold it to complete the manual edge banding.

⑧Finished the edge banding.

How to use the automatic edge banding machine?

Step 1. Select the edge banding that corresponds to the color of the sheet.

Step 2. Put the edge band on the turntable of the edge bander, and pull the interface of the edge band into the edge bander.

Step 3. Bring the sheet to the edge banding station.

Step 4. Press the board tightly and slowly push it into the edge bander.

Step 5. You can let go when it is pushed halfway, and the guide conveyor belt of the best edge banding machine will automatically bring the sheet forward and edge band.

Step 6. The board is automatically edge-sealed in the machine, and the excess part of the edge-banding strip is cut off.

Step 7. Receive the edge band at the end of the edge bander.

Step 8. Finished the edge banding.

What is the Edge Bander Used for?

The wood edge banding machine is suitable for straight edge banding and trimming of MDF, solid wood board, particle board, polymer door panel, plywood panels, and so on. It has the functions of double-sided gluing, cutting, bonding and pressing, flushing, chamfering, rough trimming, fine trimming, edge scraping, and polishing at one time. The edge is fine and smooth. And the banding equipment is stable, reliable, economical, and durable. It is especially suitable for manufacturers of large and medium-sized furniture, cabinets, and other panel furniture.

1. Pre-milling

Double milling cutters of the edge bander are used to re-modify the ripple marks, burrs, or non-perpendicular phenomena caused by panel sawing or slicing sawing to achieve a better edge banding effect. It makes the bonding between the edge band and the plate closely. And the integrity and aesthetics are better.

2. Gluing and sealing

Through the special structure of the wood edge banding machine, the edge-sealing plate and the edge-sealing material are glued evenly on both sides to ensure stronger adhesion.

3. End Trimming

Through precise linear guide motion, automatic mold tracking, and motor fast cutting, the cutting surface is even and smooth.

4. Refineming

It adopts automatic mold tracking and a high-frequency motor to ensure the smoothness of the upper and lower parts of the trimmed plate. In addition, it is used to repair the excess material above and below the edge banding strip of the processed sheet. In a word, the finishing knife is an R-shaped knife. It is mainly used for PVC and acrylic edge strips of panel furniture.

5. Scraping

The best edge banding machine for sale is used to eliminate the ripple marks caused by the cutting process of non-linear motion of trimming. And it makes the upper and lower parts of the plate smoother and neater.

6. Polishing

It uses a cotton polishing wheel to clean the processed sheet. And by polishing, it makes the edge-sealing end surface smoother.

7. Slotting

It is used for the direct grooving of wardrobe side panels, bottom panels, etc. Moreover, it is more convenient and quick to reduce the process of panel sawing. It can also be used for grooving aluminum edging of door panels.

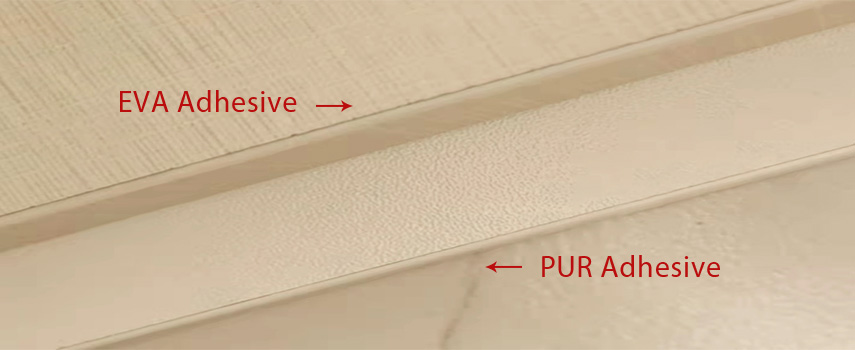

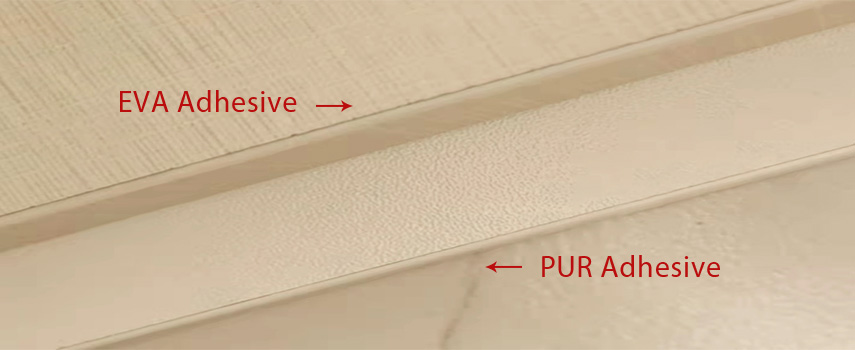

What is the Best Adhensive of the Edge Bander?

Wood edge banding machines are mostly used with hot melt adhesives. And the two most commonly used and most important hot melt adhesives are EVA (Ethylene Vinyl Acetate) and PUR (Polyurethane). Each has its pros and cons, which depend on your processed materials and banded projects. Then, in the following content, I will briefly introduce the EVA adhesive and PUR adhesive, as well as the difference between these two hot melt adhesives.

EVA Adhesive

EVA (Ethyl Vinyl Acetate) is a solvent-free, moisture-free 100% solids meltable polymer that can bond a variety of materials. When heated to a certain temperature, it becomes a flowable and viscous liquid adhesive. It becomes light brown translucent or white after melting. And it is versatile and works with almost all edge bands, including PVC, melamine, ABS, acrylic, and wood veneers. Besides, it has the advantages of good softness, elasticity, chemical stability, anti-aging, and non-toxicity. In addition, EVA is affordable and very easy to use and clean. It can be melted repeatedly, which is handy when refilling the glue compartment on the edgebander between jobs and when cleaning.

You can get filled or unfilled EVA hot melts for edge banding. Traditional EVA adhesive is filled because it has added minerals that reduce annoying "strings" and make it easier to work with. However, unfilled EVA hot melt adhesives can be applied thinner to provide a tighter connection. EVA adhesives can be specially formulated for a variety of applications. It just boils down to your work style preferences and the practicality of the job you're doing.

PUR Adhesive

PUR adhesive has extremely high moisture resistance, heat resistance, adhesion, water resistance, abrasion resistance, etc. It has become one of the important adhesives in recent years.

First of all, we should notice that the PUR hardens as it dries and cannot be remelted. This means there is little room for error and requires quick work. And PUR adhesives bond by "moisture curing", which requires being stored in airtight containers. The general storage conditions: store in a dry place protected from light, avoid excessive air humidity, and control the temperature at 8-22 ℃. Also, it expands and foams slightly as it cures. Unlike water-based adhesives that penetrate into the materials being bonded, PUR adhesives sit on the surface. Furthermore, it is also suitable for difficult-to-bond materials.

PUR glue line is more resistant to cleaning agents, making it a good choice for bathroom or kitchen products. In addition, PUR hot melt adhesive is suitable for the bonding of plastics, metals, and glass. And it is widely used in the fields of electronics, automobiles, textiles, electromechanical, aerospace, and other national economic fields.

Differences between EVA and PUR

1. Ingredients

PUR adhesive belongs to polyurethane, while EVA adhesive adopts ethylene-vinyl acetate.

2. Reaction mechanism

PUR adhesives bond by "moisture curing". It is irreversible after the reaction. But EVA adhesive belongs to physical bonding. It solidifies after cooling. And it can be remelted after heating, which is reversible.

3. Packaging and use

The packaging of the PUR hot-melt adhesive is hermetically sealed. Besides, it should be applied with professional equipment that can be sealed. But EVA hotmelts are not required.

4. Edge banding effect

We can still see a little gap in the EVA edge banding. But the PUR edge banding has no gap and is more perfect and more beautiful. In addition, professionals have done two experiments to compare the PUR edge banding and the EVA edge banding. The first experiment was to heat and then cool the two different edge banding adhesives together. We found that the EVA banding edge is easier to tear off, while the PUR banding edge-band panels are in cold water overnight. The next morning, it was found that the EVA edge-banding strips had fallen off, while the PUR edge-banding strips were intact and even tighter.

5. Environmentally friendly

PUR edge banding does not need to add any solvent, which is non-toxic and tasteless. And it will not produce any pollution or toxic gas in the environment. It is a very green edge banding method that is more environmentally friendly than EVA edge banding.

6. Cost

PUR adhesive has higher rigidity and efficiency. While the rigidity of EVA hot melt adhesive is relatively poor. And its softening point is lower than that of PUR. Most of which are around 100 °C, which limits its application range. Therefore, the price and maintenance cost of the PUR adhesive is much higher than that of the EVA adhesive.

Why Choose the Edge Banding Machines?

Edge banding is an important process in the manufacturing of panel furniture. The quality of edge banding directly affects the quality, price, and grade of the products. Through edge banding, the appearance quality of the furniture can be well improved. And it can also help you avoid the damages caused during transportation and use, such as damaged corners, and lifted or peeled-off veneers. At the same time, it can play the role of waterproof, seal the release of harmful gases, and reduce deformation. Furthermore, it can also beautify the furniture and make us feel happy.

How Much Does the Edge Banding Machine Cost?

In fact, the edge banding machine price varies a lot according to different sizes and configurations. For example, the cheap portable edge banding machine price is around $600. The best semi-automatic edge banding machine price ranges from $5, 000 to $10, 000. And the automatic large industrial edge banding machine cost is $12, 000 to $30,000. Some high-end and upgraded edge bander price is even up to $60,000. More important, we can provide you with the most suitable and economical wood edge banding machine according to your needs and budgets.

Edge Banding Machine for Small Shop

1. 380CK Semi-automatic Plywood Edge Banding Machine for Sale

The semi auto edge bander is suitable for the linear edge banding of plywood panels, solid wood boards, fibreboards, and chipboards. So it is also known as the plywood edge bander for sale, solid wood edge bander, and wood edge bander near me.

This semi-automatic edge bander for sale has 5 sections. From the left to right, it can complete the functions of gumming, aligning, fine trimming, edge banding, and polishing. The most notable feature is that it can realize both curbed edge banding and straight edge banding. And compare to the manual edge bander for sale, it has the advantages of higher efficiency.

2. W1 Folding Arm Manual Edge Banding Machine for Sale

It is a manual edge bander designed with a folding arm. The folding arm can be adjustable to conveniently realize the edge banding of wood, acrylic, PVC, and MDF. In addition, the W1 manual wood edge banding machine has a suction cup that can hold the board, which will be more convenient when edging the panel. Besides, it can process wooden panels up to 1.2m. And it can band both curved and straight edges.

3. F97 Manual Cabinet Edge Bander for Special Shapes

This curved edge banding machine adopts a plate quick positioning design to achieve ultra-thin edge banding. Therefore, you do not have to worry about insufficient glue supply and other glue problems. Moreover, it is equipped with an adjustable support roller, which can provide customers with better stability and good support. In addition, the curved edge banding machine has no limitation to the processed panel length. So you can use it to band PVC, veneer, melamine, and plastic panels with various lengths and widths you need.

Daily Maintenance of Edge Banding Machine

There may be some small problems when using the best edge bander, such as unclean polishing and aging of the machine. In fact, many of them are related to improper operation or incorrect maintenance. The edge banding machine is a large equipment that may consume a lot of manpower and materials to maintain. But good maintenance can prolong the service life of the edge bander and improve work efficiency. Therefore, it is very important to maintain the machine. So the daily care and regular maintenance of the edge banding machine is essential. The daily maintenance of the best edge bander near me mainly includes the following basic operations.

1. Regular lubrication

Lubricate the bearings of each part of the edge banding machine with lubricating oil. And be sure to select the appropriate lubricant. Otherwise, it will affect the normal use of the edge banding machine.

2. Regular inspection

Regularly inspect and maintain the edge banding machine for sale. During the maintenance, carefully check some wear conditions of gears, bearings, and other parts. And replace the severely worn parts in time. Once found, tighten them immediately, and replace the screws if necessary.

3. Clean up on time

Clean up the sawdust and various sundries generated in the production process to prevent the machine from being stuck and affecting the normal use of the machine. Secondly, it is necessary to clean up some stains on the surface of the machine in time to keep the wood edge bander clean and tidy. And it will also prevent harmful substances from causing corrosion and damage to the surface of the fuselage.

4. Clear in time

Remove waste around the edgebander and keep the operating area clean.

5. Glue amount & temperature

The amount of glue applied and the temperature of use should be adjusted according to the thickness, width, and size of the workpiece, as well as the heating capacity of the edge banding machine itself.

6. Regularly clean the glue pot

Prevent long-term high temperature heating from forming carbon deposits. Otherwise, it will affect the normal heating effect of the equipment.

7. Keep the glue return port be unobstructed

If not, the lower part of the workpiece will be dirty and the glue will also be attached to the conveyor belt and the travel switch. Thus it will affect the quality and damage the workpiece and equipment.

8. Maintain proper workshop temperature

The temperature of the CNC wood edge bander should not be too high or too low during the working process. Because if the temperature is too low, the oil will freeze and the machine will not work properly. However, thr excessive temperature can easily cause inconvenience in heat removal, thereby causing damage to the motor. Therefore, the best temperature should be kept around 20°.