With the development of the economy and urbanization, the wood processing industry has been greatly promoted, especially the demand for customized furniture industry has grown rapidly. We have to admit that the opportunity for CNC woodworking machinery to replace traditional machinery has been emerged. Whoever seizes it will take advantage of business opportunities. In this case, Blue Elephant can help you!

Machine’s profile

The machine of Furniture production line can quickly process raw materials according to different customers’ decoration preferences. On the other hand, the shape is rich and varied, the style is changeable, and the processing precision is extremely high. With those reasons, the machine promotes the development of panel furniture in the furniture industry. Moreover, in terms of process modeling, dis-assembly and assembly, and stability, the machine of furniture production line has the advantages that traditional machine cannot compare. The furniture production line can complete the cutting process efficiently, the CNC drilling and punching and other operations.

Why do you need a new choice?

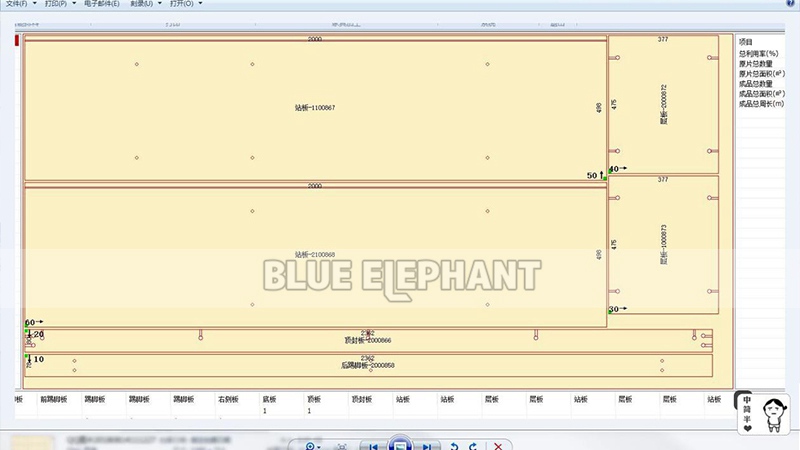

Usually, the cabinet is dismantled according to the corresponding order provided by the customer. The size of the board is manually calculated, and then the corresponding blank is handed over to the workers and let them use the cutting saw to cut the materials. However, due to the different sizes of the plates, the workers cannot arrange materials in a coordinated way. In that case, materials must be wasted. Distinct from tradition ways or machines, customized Furniture Production Line which was designed with professional opening and unpacking software can make a bill of materials directly. Its software can automatically optimize the typesetting according to the size of the sheet, generate the most reasonable typesetting, and save a lot of production costs. And the following image is a interface of machine’s software.

Customized Furniture Production Line, including 4 spindles pneumatic wood engraving machine, automatic tool-changing CNC wood router machine,etc. As for whether to use double-spindles pneumatic machines or fully-automatic loading and unloading machines, it should follow to customers’ own budget. And the final decision should be based on customers’ actual situation, such as daily output, budget, factory area and other factors.

As the leading explorer of the furniture production line, Blue Elephant has been continuously developing on the road of “automation”, “leanization” and “digitalization” to meet the requirements of customers. Blue Elephant always adheres to the concept of “customer-centered, quality first, and continuous innovation”.

Blue Elephant has deeply practiced the goal of “Made in China 2025, which is in line with smart manufacturing”. At the same time, Blue Elephant is committed to making more people in the world fall in love with “Made in China”.