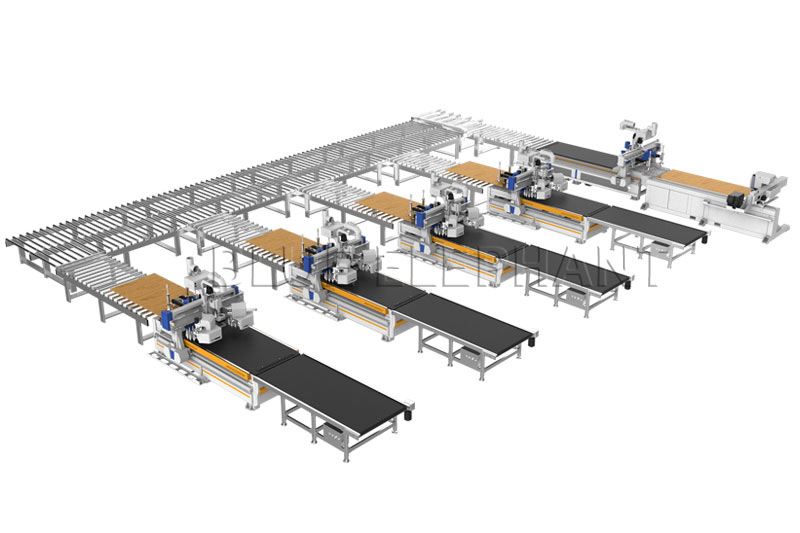

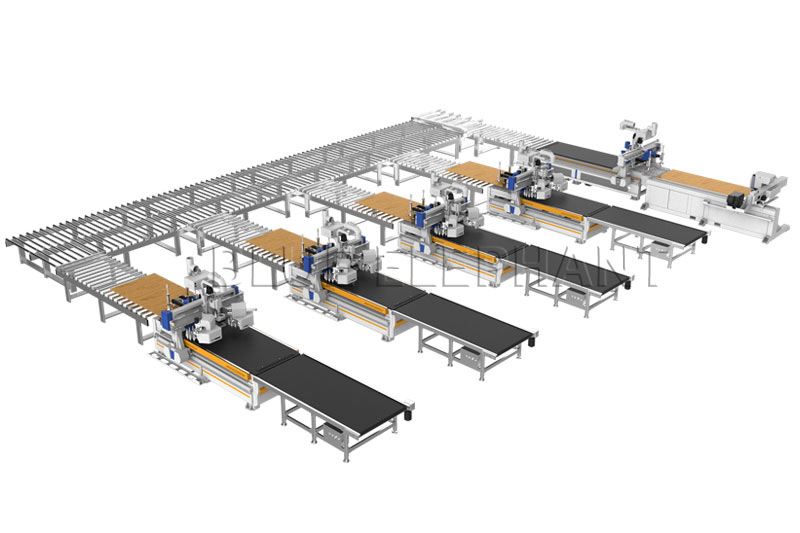

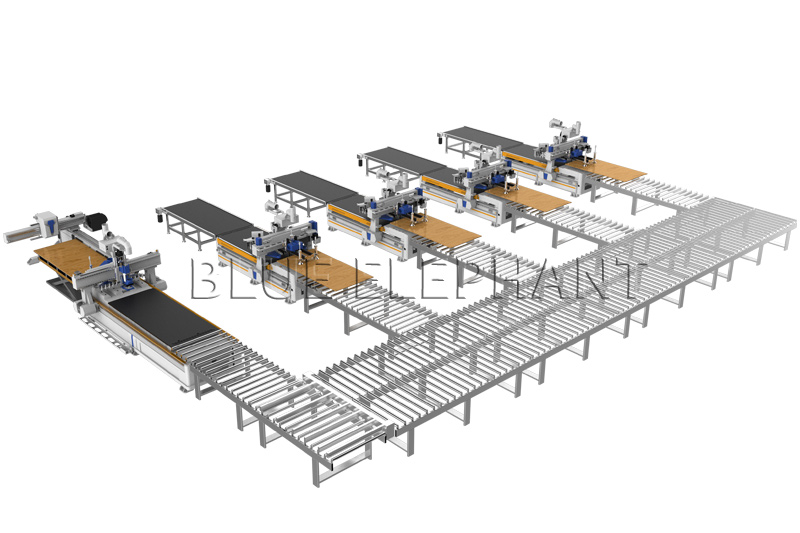

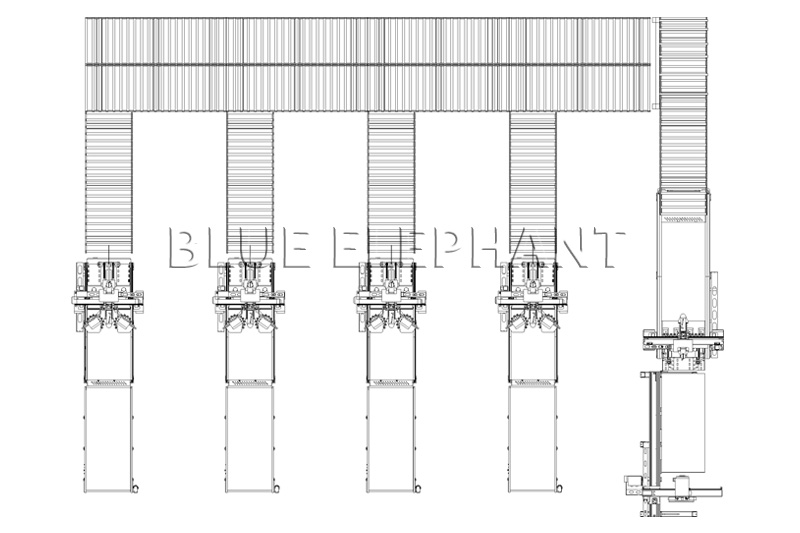

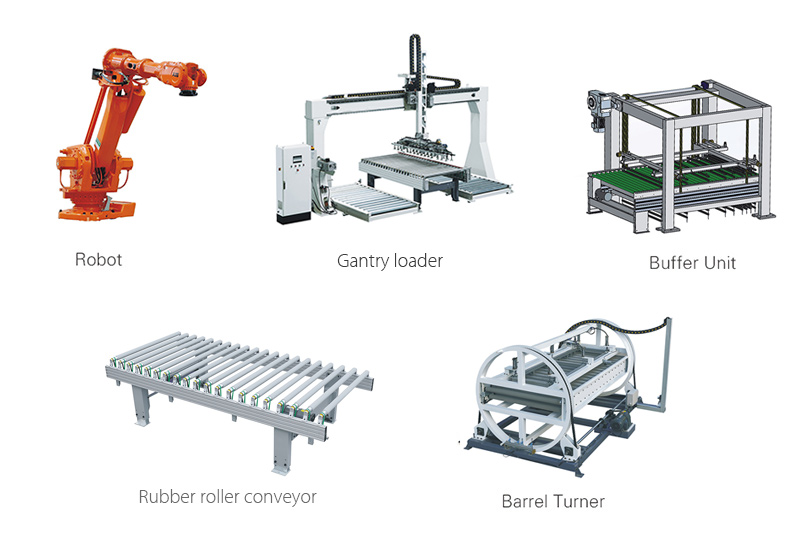

Door making assembly line is consists of labeling machine, CNC nesting machine with automatic loading and unloading, power roller line, panel turnover machine, CNC ball screw cutting machine with automatic loading and unloading. And it suitable for fully automated processing of the front and back of the molded door panel, greatly improving production efficiency and saving labor costs.

One head with four spindles door panel mould processing connection line consists of: labeling machine, CNC rack cutting machine with automatic loading and unloading, power roller line, panel turnover machine, CNC ball screw cutting machine with automatic loading and unloading

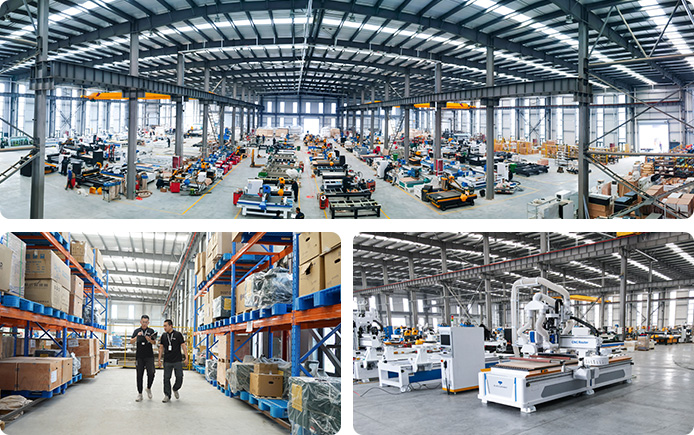

Forklift loading the plates Auto labeling machine labeling plates Machine auto grabbing plates and processing hinge hole,straightener slot, glass door back processing Plates are conveyed to turnover machine for turnover Auto delivered to separate door machining center Machine processing and cutting doors After machining, machine pushing plates to unloading table and loading plates at the same time

Click for details

Click for quotation