The term "5 axis" refers to the machine's ability to move in five different directions, allowing for greater flexibility and precision in machining operations. 5 axis CNC machines are widely used in manufacturing operations where precision, efficiency, and versatility are critical. Next, I will take you to explore the 5 axis CNC machine.

How many types of 5 axis CNC routers?

Blue Elephant CNC is a well-known Chinese 5 axis CNC machine manufacturer. We offer several types of 5 axis machining centers to meet various application requirements. Here are some common types of Blue Elephant 5 axis CNC machines for sale.

1. Bridge 5 axis CNC machine

This is a large 5 axis machining center features a bridge-like structure with a horizontal beam spanning the work area, providing stability and accuracy. It is suitable for machining large parts and heavy-duty operations.

2. Cantilever 5 axis CNC machine

This is one of the best popular 5 axis CNC machine for sale which features a movable cutting head and a suspended workpiece. It is suitable for precision machining of large workpieces, such as mold making.

3. Tabletop 5 axis CNC machine

This is the common small 5 axis machining center that has a movable worktable moving along the X, Y, and Z axes, while the cutting head can rotate around these axes. It is suitable for machining small, complex parts and precision machining.

4. Moving column 5 axis CNC machine

This type of machine features both the cutting head and the worktable that can move along the X, Y, and Z axes, while the rotating axis on the machine column allows the cutting head to rotate. They are suitable for precision machining and advanced parts manufacturing.

Blue Elephant CNC can also provide customized 5 axis machining centers according to customer requirements. The choice of which type of 5 axis machining center to use depends on the specific application and production requirements.

Top 5 Axis CNC Machine for Sale

5 Axis CNC Machining Center with Two Tables

A 5-axis CNC machining center with two tables is also known as a twin-table 5 axis CNC machine. It is a versatile and efficient machining solution that enables simultaneous processing of multiple workpieces. This type of machine typically features two movable worktables, which can be loaded and unloaded independently of each other, allowing for continuous production and reduced downtime.

3050 Large 5 Axis CNC machine for Foam

The ELECNC-3050 is a heavy-duty 5 axis CNC machining center designed for precision cutting and shaping of various materials, including metals, plastics, and composites. The machine features a robust structure made of high-quality materials to ensure durability and stability during operation. Besides, it is also equipped with advanced software and hardware technologies, such as a high-speed spindle, precision linear guides, and a user-friendly control interface.

Single Table 5 Axis CNC Machining Center for Woodworking

It is a versatile and efficient machine that is designed to process wood and wood-based materials into complex 3D shapes. It typically features a single worktable that can be rotated and tilted in multiple directions, allowing for a range of cutting and shaping operations. In addition, the 5-axis capability of the machine enables it to process wood from multiple angles, creating intricate and detailed designs with a high degree of accuracy and precision.

5 Axis CNC Router Kits

1. 5 axis CNC machine bed

The machine bed is the main body of the 5-axis CNC router, which provides a sturdy platform to support the other components of the machine.

2. 5 axis Spindle

The spindle is the rotating component that holds the cutting tool and performs the cutting operation. It is driven by a motor and can rotate around multiple axes.

3. 5 axis Cutting tools

Cutting tools are mounted on the spindle and can be changed based on the specific cutting requirements. Different types of cutting tools are available for various materials and cutting operations.

4. 5 axis workholding device

The workholding device is used to hold the workpiece securely in place during the cutting operation. Different types of workholding devices, such as clamps, vacuum fixtures, and chucks, can be used depending on the shape, size, and material of the workpiece.

5. 5 axis CNC control system

The control system is responsible for the overall operation of the machine, including movement and coordination of the axes, speed and direction of the spindle, and control of the cutting tools. It consists of a computer, a CNC controller, servo motors, and encoders.

6. 5 axis rotary table

A rotary table is a device that can rotate the workpiece around its axis while the cutting tool is stationary. This allows for machining of complex shapes and features that would not be possible with a traditional 3-axis machine.

7. 5 axis cooling system

A cooling system is used to lubricate and cool the cutting tool and the workpiece during the machining process. It helps to prevent overheating and prolongs the life of the cutting tool.

Wearing Parts of 5 Axis CNC Router

Cutting tools

The cutting tools are one of the most frequently worn parts of a 5-axis CNC router. The high-speed rotation and cutting force can cause the tools to wear down and become dull over time. Regular maintenance and replacement of cutting tools is necessary to ensure optimal cutting performance.

Bearings and guide rails

Bearings and guide rails are also wearing parts of a 5-axis CNC router. They support the weight of the machine and the movement of the axes, and can wear down due to constant friction and stress. Regular cleaning and lubrication, as well as timely replacement, can help extend their lifespan.

Belts and pulleys

Belts and pulleys transmit power and motion between the motors and the machine components. They can stretch, slip, or wear out over time, which can cause inaccuracies or loss of power. Regular inspection and replacement of worn belts and pulleys can help ensure the machine's precision.

Spindle motor

The spindle motor is the driving force behind the cutting tool, and is subjected to constant high-speed rotation and vibration. Over time, the motor can wear down or fail, which can affect the machine's performance. Regular maintenance and monitoring of the spindle motor can help prevent costly breakdowns.

Electrical components

The wiring, connectors, and other electrical components in a 5-axis CNC router can also wear out over time due to heat, vibration, and stress. Regular inspection and maintenance of the electrical system can help prevent malfunctions and ensure safe operation.

Advantages of 5 Axis CNC Machine

Greater precision

A 5-axis CNC router can move a cutting tool in five different directions, allowing for greater precision and accuracy in cutting and shaping materials. This results in a higher quality finished product and reduces the need for additional manual finishing work.

Increased efficiency

With the ability to cut and shape a workpiece from multiple angles, a 5 axis CNC router can complete complex tasks in a single setup, reducing the need for multiple setups and reducing production time.

Versatility

A best 5 axis CNC machine can handle a wider range of materials and shapes, making it suitable for a variety of applications, including aerospace, automotive, medical, and defense industries.

Improved surface finish

The multiple axes of a 5-axis CNC machine allow for smoother and more consistent cutting, resulting in a better surface finish on the workpiece.

Reduced waste

With greater precision and accuracy, a 5-axis CNC machine can minimize material waste, which reduces costs and is more environmentally friendly.

Flexibility

5-axis CNC machines are designed to handle a variety of machining operations, including milling, turning, and drilling, making them a versatile tool for manufacturers.

Multi-axis machining capability

5 axis CNC machines have the ability to perform complex machining operations by allowing the cutting tool to move in five directions simultaneously. This enables the machine to create parts with intricate geometries that would be difficult or impossible to produce with a 3-axis machine.

Reduced setup time

With high efficiency 5 axis CNC machines, complex parts can be produced in a single setup, reducing the amount of time and labor required for multiple setups.

Improved tool life

With 5 axis machining, the tool can be held perpendicular to the part surface, reducing tool wear and increasing tool life.

What Materials Can the 5 Axis CNC Machine Process?

- Metal: aluminum alloy, titanium alloy, stainless steel, copper, iron, steel, etc.

- Plastic: polyurethane, polypropylene, polyethylene, polystyrene, polyvinyl chloride, etc.

- Wood: all kinds of hardwood, cork, wood-based panels, etc.

- Composite materials: FRP, carbon fiber, fiber reinforced plastics, etc.

What Kinds of 5 Axis CNC Projects Can We Make?

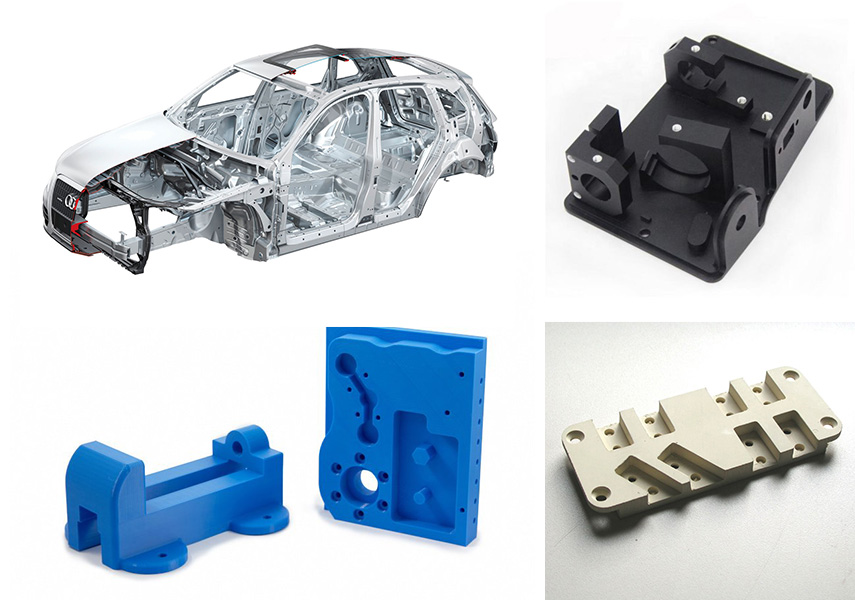

A 5 axis CNC machine can make a wide range of products and components, depending on the materials and cutting tools used. Here are some examples of products that can be made with a 5 axis CNC machine.

Aerospace components

Turbine blades, fan blades, combustion chambers,wing spars, bulkheads, ribs, wheels, brakes, struts, sensors, switches, and displays, rocket nozzles, fuel injectors, etc.

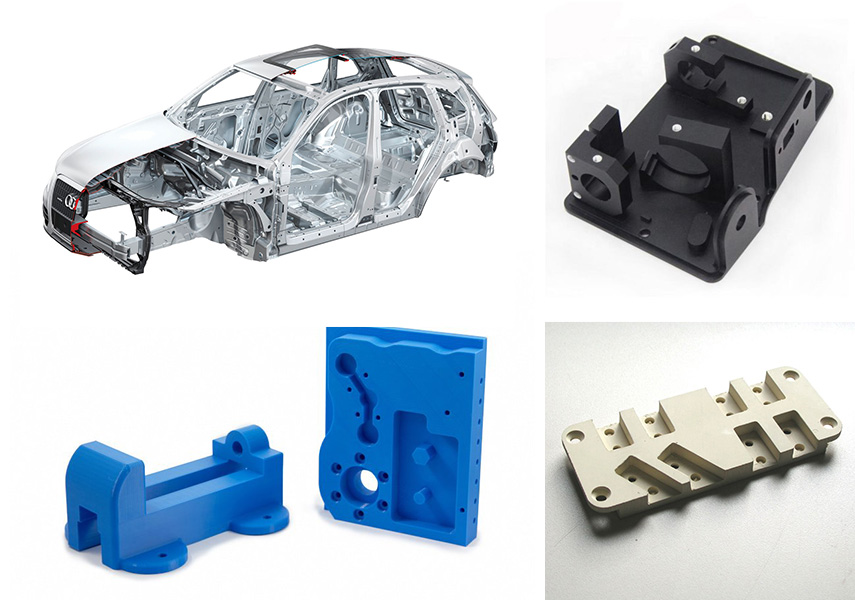

Automotive parts

Cylinder heads, crankshafts, control arms, knuckles, bushings, brake rotors, calipers, and pads, gears, shafts, body panels, trim pieces, etc.

Furniture

Different types of furniture, such as tables, chairs, cabinets, shelves, etc.

Medical devices

Custom orthotics, prosthetics, implants, surgical instruments, and many other devices.

Signage

Different types of signage, such as 3D lettering and logos, etc.

Prototypes

Rapid prototyping of different parts and products can be done with a 5 axis CNC machine.

Sculptures

The CNC machine can work with a variety of materials, including wood, stone, metal, and more. This means that sculptors have a lot of flexibility when it comes to choosing the materials they want to work with, and can create sculptures that are durable and long-lasting.

Mold making

Molds for casting and shaping different materials can be manufactured with a 5 axis CNC machine.

5 Axis CNC Machine Price

The a 5 axis CNC machine price can vary widely depending on various factors such as the size, features, complexity, and brand of the machine. Generally, a basic 5-axis CNC machine with a small cutting area can cost around $50,000-$100,000, while a larger, more advanced model with greater precision and cutting capabilities can cost upwards of $500,000 or more.

It's important to note that the price of a 5-axis CNC machine is just one part of the total cost of ownership, which includes maintenance, software, training, and other factors. It's important to carefully consider your needs and budget before investing in a 5-axis CNC machine.

What Size of Business is 5 Axis CNC Machines Suitable for?

5 axis machines are suitable for a range of businesses. For example, there are 5 axis CNC machine for home, 5 axis CNC machine for small business, industrial 5 axis CNC machine, etc. It depends on the specific needs of the business. The size of business that a 5-axis machine is suitable for can be determined by factors such as the volume and complexity of the parts being manufactured, the level of automation required, and the available budget for equipment.

Smaller businesses may benefit from a 5-axis machine if they require the high precision and accuracy offered by such machines for their manufacturing operations. For example, a small business involved in prototyping or producing highly complex and intricate components may find a 5-axis machine to be a valuable investment, as it can help them produce parts quickly and with high precision, leading to faster product development and a competitive advantage.

Larger businesses may have more resources to invest in multiple 5-axis machines for their manufacturing operations, allowing them to increase their production capacity and improve efficiency. For example, a large automotive manufacturer may use 5-axis machines to produce large quantities of complex engine parts with high accuracy and efficiency.

Overall, 5-axis machines can be a valuable investment for businesses of all sizes that require high precision and accuracy in their manufacturing operations, but the specific size and type of 5-axis machine will depend on the unique needs of the business.

Since a 5 axis CNC machining center is a high-precision machining equipment, customer reviews of it are usually positive. The following are some typical evaluations of five-axis CNC machining centers by customers from various countries.

Evaluation of 5 Axis CNC Machine in Different Countries

The use and evaluation of 5 axis CNC router machines can vary significantly between different countries, depending on a variety of factors such as the level of technology adoption, industry demand, and manufacturing standards. Here is an overview of the use and evaluation of 5-axis CNC machines in some representative countries.

5 Axis CNC Machine for Sale in Japan

Japan is one of the leading producers of five-axis CNC machining centers and is a significant market for this technology. Japanese customers generally praise the high precision, efficiency, and stability of five-axis CNC machining centers, which they see as crucial to improving their manufacturing capabilities and product quality.

5 Axis CNC Machine for Sale in Germany

Germany is one of the world's leading manufacturing centers and a significant market for five-axis CNC machining centers. German customers typically appreciate the high precision and stability of these machines, which they consider key to improving manufacturing quality and productivity.

5 Axis CNC Machine for Sale in the US

The United States is one of the world's largest economies and a major market for five-axis CNC machining centers. Many American customers believe that five-axis CNC machining centers can improve their manufacturing capabilities and flexibility, allowing them to respond more quickly to market demands.

5 Axis CNC Machine for Sale in China

China is the world's largest manufacturing country and one of the leading producers of five-axis CNC machining centers. Many Chinese customers consider five-axis CNC machining centers to be crucial to improving China's manufacturing competitiveness, enabling them to produce high-quality products and increase production efficiency.

5 Axis CNC Machine for Sale in India

India has a developing manufacturing industry, and the use of 5-axis CNC machines is still relatively limited. However, there is growing interest in these machines as Indian manufacturers seek to improve their capabilities and compete on the global stage.

How to Use the 5 Axis CNC Machine for Beginners?

Here are some general steps for using a five-axis CNC machine:

Step 1 Design the part to be machined

The first step is to design the part that you want to create using a CAD (Computer-Aided Design) software.

Step 2 Generate the toolpath

Once the part design is complete, the next step is to generate a toolpath using a CAM (Computer-Aided Manufacturing) software. The toolpath is a set of instructions that tell the CNC machine how to move the cutting tool to create the part.

Step 3 Set up the machine

Before starting the machining process, the operator needs to prepare the machine for use. This involves selecting the correct cutting tool, attaching it to the spindle, and setting the workpiece in the machine's work area.

Step 4 Load the program

Once the machine is set up, the operator loads the toolpath program into the machine's control system. This program includes all the instructions required to create the part, including the toolpath, cutting speed, and feed rate.

Step 5 Run the program

After loading the program, the operator initiates the machining process. The machine will follow the toolpath program and use the cutting tool to remove material from the workpiece to create the part.

Step 6 Inspect the part

Once the machining process is complete, the operator inspects the part to ensure that it meets the required specifications.

Step 7 Repeat the process

If multiple parts need to be produced, the operator repeats the process by loading the next toolpath program and workpiece, and starting the machining process again.

It's important to note that the specific steps for using a five-axis CNC machine may vary depending on the machine's manufacturer and model, as well as the complexity of the part being machined. Additionally, the operator must have a good understanding of the machine's capabilities, cutting tools, and programming language to operate the machine safely and effectively.

How to Maintain the 5 Axis CNC Machine?

Proper maintenance is essential to keep a five-axis CNC machine operating at peak performance and to extend its lifespan. Here are some general tips on how to maintain a five-axis CNC machine:

1. Keep the machine clean

Regularly clean the machine's work area, cutting tools, and other components to prevent the buildup of dirt, dust, and debris, which can affect the machine's accuracy and performance.

2. Lubricate moving parts

Regularly lubricate the machine's moving parts, such as the spindle, ball screws, and linear guides, to reduce friction and prevent wear and tear.

3. Check for wear and damage

Routinely inspect the machine's components, including cutting tools, bearings, and belts, for wear and damage. Replace any damaged or worn parts promptly to prevent further damage to the machine.

4. Calibrate the machine

Periodically calibrate the machine's components to ensure that they are operating within their specified tolerances. This includes checking the machine's alignment, spindle runout, and cutting tool accuracy.

5. Check coolant levels and filters

If the machine uses coolant, regularly check the coolant levels and filters to ensure that they are clean and functioning correctly. Dirty coolant can affect the machine's accuracy and cause premature wear on its components.

6. Follow the manufacturer's recommendations

Follow the manufacturer's recommended maintenance schedule and procedures to ensure that the machine operates correctly and to avoid voiding the machine's warranty.

By following these general maintenance tips, you can keep your five-axis CNC machine running smoothly and efficiently, and help to extend its lifespan. However, it's essential to check the specific maintenance requirements and recommendations for your machine, as they may vary depending on the manufacturer and model.

Conclusion

In conclusion, 5 axis CNC machines are a highly advanced type of machine tool used in manufacturing to produce complex and precise parts. They offer several advantages over traditional 3-axis machines, including increased precision, reduced setup time, improved efficiency, and greater versatility.

The use and evaluation of 5-axis CNC machines can vary significantly between different countries, depending on factors such as industry demand, manufacturing standards, and technological adoption. However, they are widely used in industries such as aerospace, automotive, medical, and more, where precision, efficiency, and versatility are critical.

As technology continues to evolve, it is likely that 5-axis CNC machines will become even more advanced, with new features and capabilities that further improve their performance and efficiency. For manufacturers, investing in 5 axis CNC machines can provide a significant competitive advantage, allowing them to produce high-quality, complex parts in a cost-effective and efficient manner.