Metal cutting is a common process in modern manufacturing, and it plays an important role in many industries, including automobile manufacturing, aerospace, electronic equipment and more. In the metal cutting process, there are two common technologies that get a lot of attention: metal numerical control machines (CNC) and metal laser cutting machines. Both technologies have unique advantages and scope of application, but for different application requirements, which technology is more suitable for metal cutting?

In this article, we will explore the features, advantages and limitations of metal CNC machines and metal laser cutting machines. We'll compare them in terms of cutting speed, accuracy, material suitability, cost-effectiveness, and more. By knowing this information, you will be able to better understand which technique is better for your metal cutting needs.

Whether it is metal CNC machine tools or metal laser cutting machines, they all play an important role in modern manufacturing. Their differences make each of them have their own advantages in different situations. Through in-depth research and comparisons, you'll be able to make an informed choice to meet your metal cutting needs and increase productivity and quality.

What is CNC metal cutting machine?

A CNC metal cutting machine is a type of automated machine tool used for cutting, shaping, and machining metal workpieces with precision and accuracy. It utilizes computer-controlled movements and commands to guide the cutting tool, allowing for highly efficient and consistent metal cutting operations.

The CNC metal cutting machine is equipped with a cutting tool, such as a rotating milling cutter or a high-powered laser, which removes material from the workpiece to achieve the desired shape or cut. The machine's movements are controlled by a computer program that specifies the cutting path, tool speed, and other parameters.

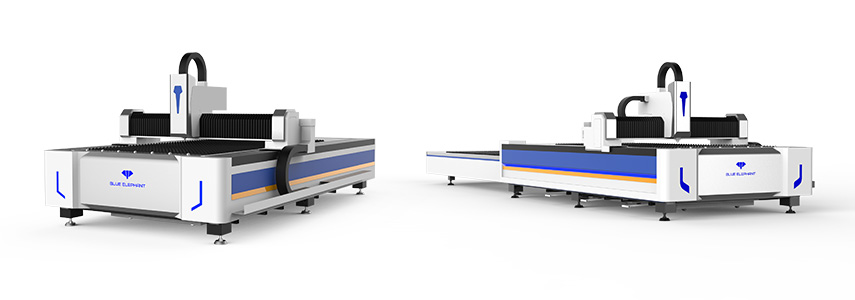

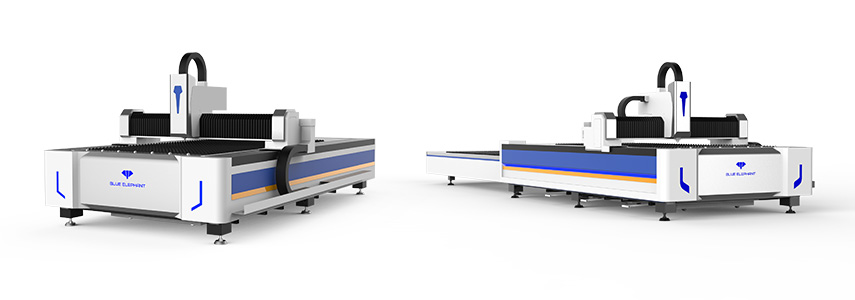

What is metal laser cutting machine?

A laser cutting machine is a machine that uses a laser beam to cut. It uses high-energy-density laser beams to cut materials through heating and evaporation. Laser cutting machines are widely used in industry, especially in metal processing and manufacturing industries. Optical cutting machine can precisely cut metal materials and non-metal materials, such as steel, stainless steel, aluminum, plastic, wood, etc. It can realize straight line cutting, curved cutting and complex shape cutting, from simple planar parts to complex three-dimensional structures.

Differences between metal CNC machine and metal laser cutter

1. Principle

Laser cutting machine: A laser cutting machine uses a high-energy laser beam to cut material. The laser beam is focused to an extremely small spot, and the material is cut by heating and vaporizing.

Plasma Cutters: Plasma cutters use high-temperature plasma to cut materials. During plasma cutting, gas is activated by an arc discharge to form a plasma, which is focused through a nozzle onto the material for cutting.

2. Cutting quality

Laser cutting machine: The laser can achieve metal cutting accuracy within 0.2mm. In addition, the laser cutting machine can complete the non-contact cutting with the surface of the product workpiece, the cutting gap is small, the precision is high, the heat hazard area is small, and the cutting inner hole is smooth and free of burrs.

Plasma cutting machine: Plasma can be done within 1mm, but the cutting gap is slightly larger, the cutting inner hole is not smooth and uneven, and the cutting precision is low.

3. Cost

Laser cutting machine: It is composed of many high-precision parts, and the cost of mechanical parts is high. However, because it is basically maintenance-free, the cost of consumables is very low.

Plasma cutting machine: The purchase price is relatively cheap, but the cost of consumables is very high. For example, the entire torch needs to be replaced within hours, and the plasma cutter uses a lot of electricity.

4. Use environment

Laser cutting machine: Laser cutting machines usually require a relatively clean and closed working environment to ensure the stability and cutting quality of the laser beam.

Plasma cutting machine: The plasma cutting machine has relatively low requirements on the working environment, and it can be used in harsh environments.

Metal CNC cutter or Metal laser cutter: which one to choose?

Whether you choose a metal laser cutter or a plasma cutter depends on your specific needs and situation. If you need high-speed and efficient cutting, or pursue higher cutting quality and precision, then a laser cutting machine may be a better choice. In addition, metal laser cutting machines are suitable for a variety of metal materials, including steel, stainless steel, aluminum, and more. Plasma cutters are also suitable for all kinds of metal materials, but there may be some limitations for some highly reflective materials such as copper and aluminum. However, if you need to cut thicker sheet metal, then a plasma cutter is more advantageous. Again, depending on budget and real economics, plasma may be less expensive to purchase. But in the long run, laser cutting is more recommended, because it is more environmentally friendly and efficient, and will bring greater benefits.

6 advantages of laser cutting machine

1. Laser cutting speed is faster: the cutting speed of sheet metal parts can reach 10m/min, far exceeding that of plasma cutting machines.

2. High cutting quality: the deformation is small, and the cutting cabinet table is smooth. The cutting groove is not large, and the cutting surface can be directly used for welding without grinding.

3. High-precision cutting: the precision of laser cutting machine can reach 0.05mm, and the repeat accuracy level can reach 0.02mm.

5. The application of laser cutting raw materials covers a wide range: metal materials and non-metal materials can be used. There are metal material laser cutting machines and CO2 laser cutting machines suitable for non-metal materials.

6. The laser can also be used for various other operations such as engraving, welding, drilling, etc., with complete functions.

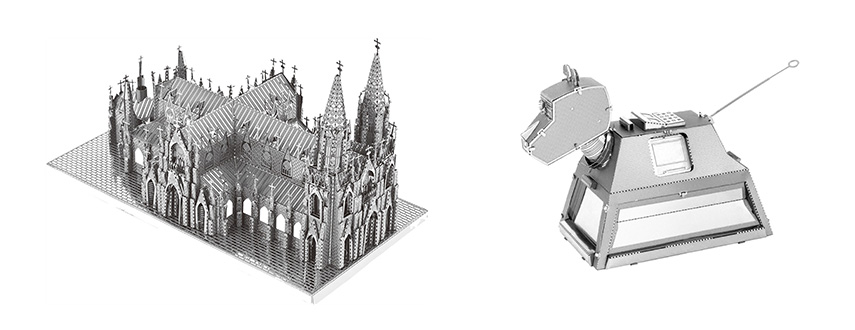

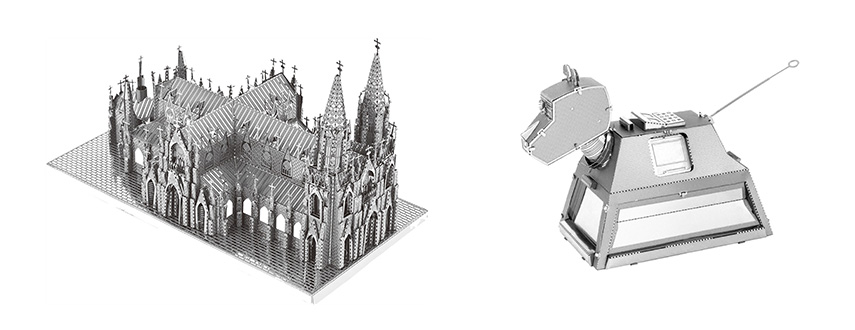

What can you make with a metal laser cutting machine?

A metal laser cutting machine can be used to create a wide range of products and components. Here are some examples of what you can make with a metal laser cutting machine:

Metal Parts and Components

Laser cutting allows for the precise cutting of various metal parts and components used in industries such as automotive, aerospace, electronics, and machinery manufacturing. This includes sheet metal parts, brackets, frames, enclosures, gears, and more.

Decorative Metal Artwork

Laser cutting enables intricate and detailed designs, making it ideal for creating decorative metal artwork. This can include wall hangings, sculptures, signs, ornaments, and custom designs.

Metal Signage and Lettering

Laser cutting can be used to produce metal signage, lettering, and logos for indoor and outdoor applications. It allows for precise cutting of different metals, creating professional and customized signage.

Metal Jewelry and Accessories

Laser cutting is commonly used in the production of metal jewelry and accessories. It enables intricate designs, precise cutting of patterns, and customization of metal pieces such as earrings, necklaces, bracelets, and keychains.

Prototypes and Models

Laser cutting is often utilized for the rapid production of prototypes and models. It allows for quick and precise fabrication of metal parts, facilitating product development and design validation.

Architectural and Decorative Metal Features

Laser cutting can be employed to create architectural and decorative metal features such as intricate patterns, screens, panels, grilles, and railings. These features can enhance the aesthetics of buildings and interior spaces.

Custom Metal Fabrication

Laser cutting machines provide flexibility for custom metal fabrication projects. Whether it's cutting unique shapes, creating one-of-a-kind designs, or personalized metal products, laser cutting offers versatility for custom fabrication requirements.

The metal laser cutting possibilities are vast, and the specific items you can create with a metal laser cutting machine depend on your creativity, design capabilities, and the materials at your disposal. Laser cutting offers precision, versatility, and the ability to work with various metals, making it a valuable tool for many industries and applications.