Blue Elephant bathroom production equipment is famous for its high performance, high efficiency, and high quality. It provides a series of bathroom solutions for bathroom manufacturers, including bathroom cabinets, floating bathroom vanity, bathroom sink, bathroom washbasins, bathroom trays, and so on. And it has solved a large number of bathroom production problems, creating a comfortable and beautiful bathroom environment for people.

This article will start from two main aspects- bathroom production equipment and bathroom solutions. So that you can better know about the features and productive process of various bathroom products. So as to find the bathroom solution you need most and satisfy you most.

Common Bathroom Production Equipment

Whether it is in a family, in a hotel or in the public place, most of the bathroom equipment is made of wear-resistant, durable, and corrosion-resistant stone materials like marble, limestone, granite, sandstone, slate, and quartz. In order to meet the processing needs of more bathroom manufacturers, Blue Elephant has designed and launched a variety of advanced stone cutting machines, such as stone CNC machines and stone CNC machining centers. The following are the three most popular quartz stone CNC machining centers.

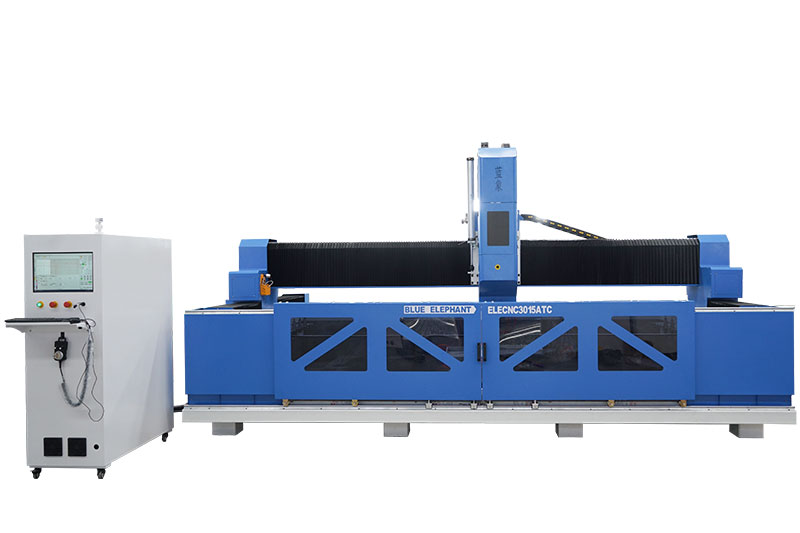

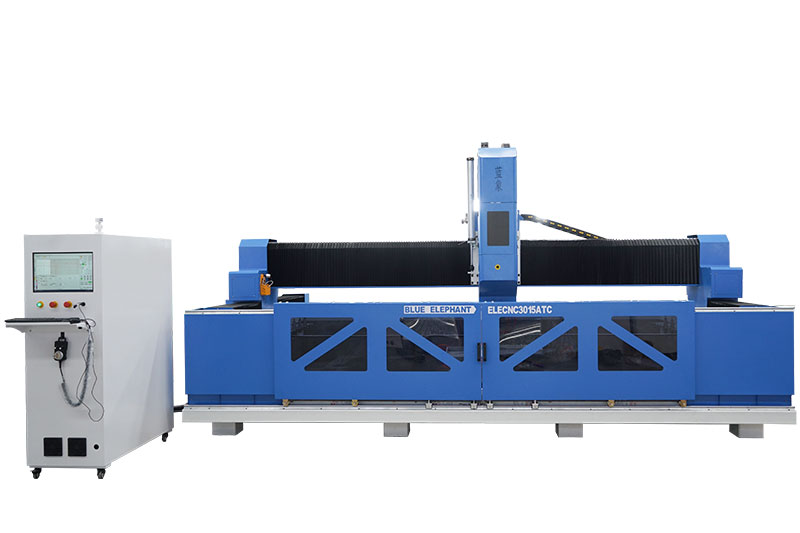

3015 Quartz Countertop Stone CNC Machining Center

Parameters

| System |

Weihong |

| Tool magazine |

12 tools |

| Spindle |

Jianchun water cooling spindle |

| Table |

Phenolic board hard countertop with 8 suction cups |

| Lubrication system |

Electric gear pump |

| Spray/Sink |

Center Spray+ Ring Spray+ Sink |

| Voltage |

380v,3ph,50hz |

Video

5 Axis Stone Bridge Saw for Sale

The 5 axis CNC bridge saw is the newest high-end stone CNC processing center launched by Blue Elephant. Combination of saw blade and cutter, the stone bridge saw is multi-functional and powerful to realize engraving, thickness measurement, automatic knife setting, suction cup adsorption, 45-degree bevel cutting, arc cutting, oval cutting, sector cutting, polygon cutting, pot hole digging, drilling, etc. It is widely used in stone processing plants, kitchen countertop processing, bathroom countertop processing, background wall profiling, and other stone machining fields.

Features

- Equipped with a self-developed 5-axis bridge cutting head, the spindle can rotate 360°to realize advanced functions, such as straight line cutting, edge chamfering, arc cutting, polygon cutting, special-shaped milling, edge grinding, profiling, and 45°bevel cutting.

- Adopting an automatic turning table, it is convenient for unloading materials and can reduce labor intensity.

- Using high-precision RV reducer, the cutting head swings with higher precision.

Parameters

| System |

Blue Elephant Customization System |

| Table size |

3200mm × 2000mm |

| Flip angle |

0-80° |

| Reverse weight |

800KG |

| Saw blade size |

450mm |

| Maximum processing thickness |

100mm |

Video

Two-process Marble Stone CNC Machining Center

Features

- Double spindles are adopted that edging and engraving can be switched with one key, which is easy to operate.

- This stone cutting machine for marble countertops can realize quick tool change in 3 seconds, with more -functions and higher processing efficiency.

- It can be switched automatically according to the processing requirements, which reduces the tool changing time and improves the processing efficiency.

Parameters

| System |

Weihong system |

| Table size |

1500*3000*200mm |

| Lubrication system |

Automatic lubrication system |

| Spray/Sink |

Sink |

| Voltage |

380v,50hz,3ph |

Video

5 Solutions for Bathroom Designs

The production plan of bathroom products refers to the product design plan for specific bathroom scenarios or needs. It needs to consider multiple aspects such as product functions and user experience to solve various problems of users in the use of bathroom. The following are several common production schemes for bathroom products, which can solve the production and processing needs of bathroom products such as home bathrooms and hotel bathrooms.

1. Bathroom cabinet solution

Bathroom cabinets are an integral part of bathroom furniture. They are often used to store hygiene products, towels, clothing, and other items. They are usually placed in the bathroom, where messy items can be placed neatly, improving the cleanliness of the bathroom and the efficiency of space utilization. At the same time, the bathroom cabinets can also beautify the bathroom. In addition, the materials of bathroom cabinets are usually made of MDF, solid wood, artificial stone, etc., with diverse colors, sizes, styles, and functions according to your different needs.

So how to make a practical and beautiful bathroom cabinet? Don't worry, Blue Elephant has tailored an intelligent bathroom cabinet production line for customers, which can process bathroom cabinets for you in one stop.

The following is the Blue Elephant bathroom cabinet production line, including CNC cutting machine, edge banding machine, side drilling machine, vacuum press machine, and stone CNC machining center. This production line not only reduces the errors that may be caused by human intervention, but also greatly improves the production efficiency, saves materials, reduces costs, and brings greater benefits.

①Cabinet cutting machine

Introduction:

Introduction: The linear ATC CNC machining center can carve wood products such as doors, cabinets, tables, chairs, and windows. It has an independent tool magazine, which can automatically replace the required tools during the processing without stopping the work.

Features:

- It is suitable for multiple and complex product processing.

- It can realize various functions like drilling, cutting, side milling, chamfering, etc.

- Linear automatic tool changer is with a capacity of 12 tools, which has fast tool change time and high efficiency.

②Automatic edge banding machine

Introduction:

Introduction: It is suitable for panel furniture, customized furniture, office furniture, solid wood furniture, decoration industries, etc. Moreover, it can process density boards, ecological boards, multi-layer boards, particle boards, aluminum honeycomb panels, and so on.

③Side hole drilling machine

Introduction:

Introduction: The side hole machine is designed and developed for panel furniture wardrobes. It is suitable for the design of cabinet wardrobes and panel furniture. It can complete three-in-one side holes, wood pin holes, blind holes, fixed slots, through slots, etc.

Features:1. Laser scanning will accurately locate and intelligently judge the punching position.

2. Customized limits can ensure high safety protection.

3. It is convenient and quick to scan and punch holes.

4. Various punching modes can be switched freely to meet different process requirements.

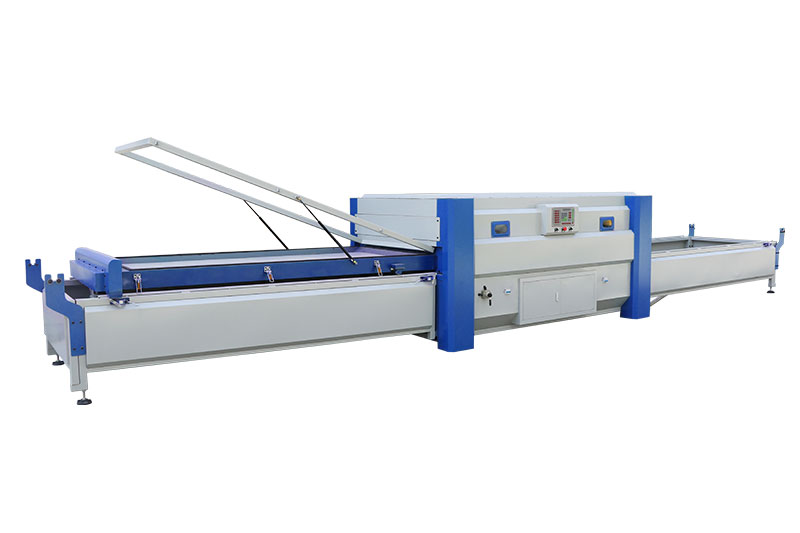

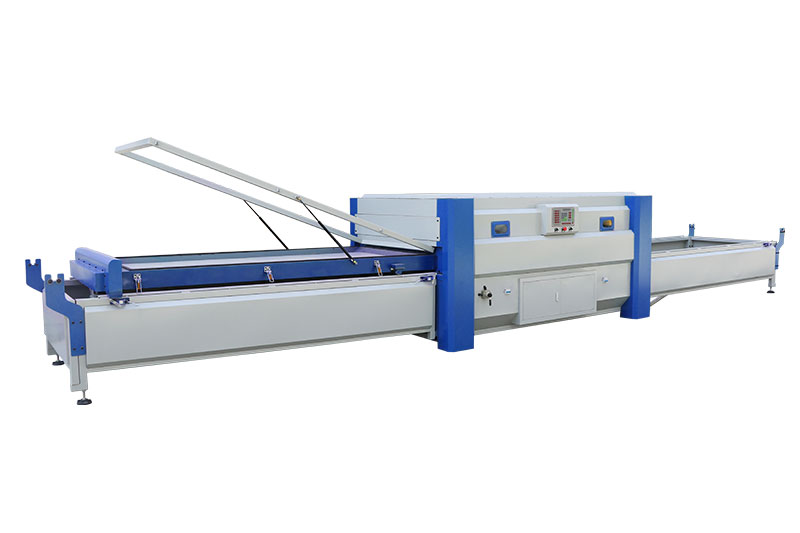

④Vacuum press machine

Introduction:

Introduction: it can apply various PVC films on furniture, cabinets, speakers, paint-free doors, and other materials for 3D filming. And it can be used for hot stamping films and single-sided solid wood veneers after adding silica gel plates.

Features:1. The body is welded by high-quality steel, which has high stability without deformation.

2. Adopts a microcomputer temperature controller, so as to adjust the heating speed to achieve the temperature control.

3. Using automatic digital display technology, the whole machine has high degree of automation, simple operation, and low failure rate.

⑤Stone CNC machining center

Features:

Features:1. The table is made of phenolic board hard table with 8 suction cups, which has high stability.

2. 12 tool magazines can automatically change tools to save working time.

3. It has a wide range of applications. For instance, it can make countertops, washbasin digging, mural processing, background wall lettering, relief, hollowing out, etc.

2. Bathroom vanity solution

A floating bathroom vanity is a common piece of bathroom furniture that is often used to store cosmetics, toiletries, etc. Different from the traditional bathroom vanity, the floating bathroom vanity adopts a hanging design. Thus it can be fixed on the wall without taking up floor space, and making the bathroom more tidy and beautiful. In addition, the material of the floating bathroom vanity is usually made of waterproof materials, such as artificial stone, granite, marble, quartz, PVC, acrylic, and so on. Its appearance design can be selected according to personal preferences.

3. Bathroom sink solution

Wall-mounted bathroom sinks are a very popular bathroom fixture. Unlike traditional countertop sinks, the wall-mounted bathroom sinks are hung on the wall without a base, saving space. And wall-mounted bathroom sinks are usually made of ceramics and stones. Their surfaces are smooth and easy to clean. Some designers also make creative designs to make them not only practical but also aesthetically pleasing.

4. Bathroom tray solution

The bathroom tray is a small piece of furniture used in the bathroom. It is easy to move and clean. And it is usually used to place toiletries, cosmetics, bathing utensils, and other items. Because wood is prone to blisters, metal is rusty, and plastic is easy to oxidize, stone bathroom trays and plastic bathroom trays are more common.

5. Bathroom mold solution

Bathroom molds play an important role in the bathroom production. It is a tool specially used to make sanitary products, such as bathtubs, shower enclosures, toilets, sinks, etc. They are usually made of steel, aluminum, plastic, foam, and other materials in different sizes and shapes. And the best production equipment to realize this complex 3D design is the Blue Elephant 5-axis CNC machining center.

The 5 axis CNC machining center adopts a gantry worktable to ensure that the machine has good dynamic motion and driving rigidity. Besides, its main parts have undergone two strict aging treatments, which not only reduces the deformation stress, but also increases the stability. And he can also complete five-sided machining in one clamping. On the one hand, it reduces the number of clamping times. On the other hand, it also ensures the good machining accuracy. The following video shows the whole process of manufacturing a foam toilet mold with a 5-axis CNC machining center.

Video

Conclusion

The bathroom production requires bathroom manufacturers to have excellent design capabilities and quality control capabilities to ensure that the products meet market demand. With 12 years of CNC machine manufacturing experience, a professional technical team of more than 300 people, and a high-level professional factory of 45,000㎡, Blue Elephant has sufficient strength to provide professional bathroom production equipment and bathroom solutions for bathroom manufacturers. If necessary, Blue Elephant will provide you with more bathroom solutions in the future, such as family bathroom solutions, hotel bathroom solutions, public place bathroom solutions, smart bathroom solutions, etc.