Stone CNC Machines: A Brief Overview

Stone CNC machines are specifically designed to handle tasks like cutting, carving, engraving, and polishing stone materials with precision and efficiency.

Types of Stone CNC Machines

CNC Router: These machines use rotating cutting tools to carve and engrave designs onto stone surfaces. They're highly versatile and can handle a wide range of stone materials.

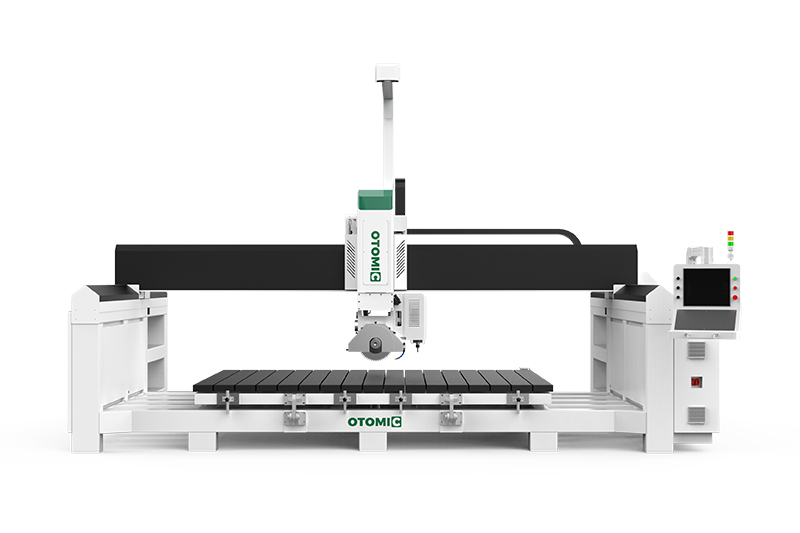

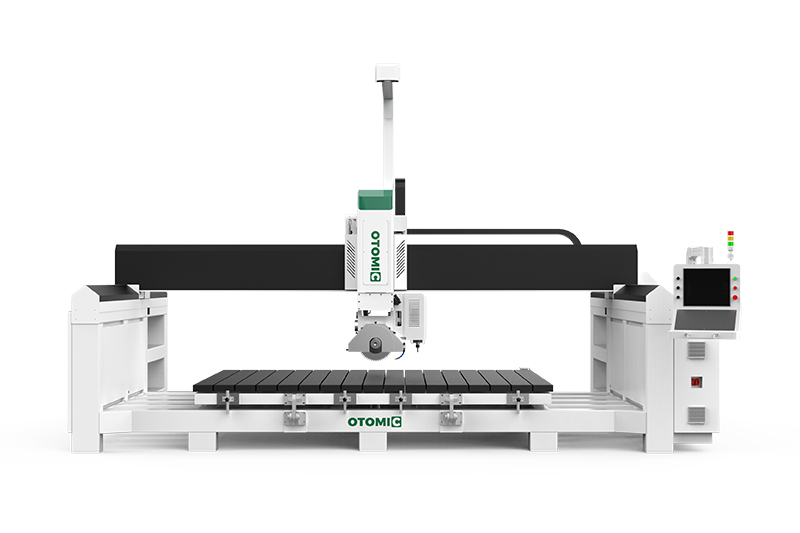

CNC Bridge Saw: Bridge saws are used primarily for cutting stone slabs into specific shapes and sizes. They feature a bridge-like structure with a rotating blade that cuts through the stone.

CNC Machining Center: A CNC machining is an equipment that realizes stone processing through computer control system. It can accurately perform cutting, engraving, drilling and other operations according to pre-designed processing procedures. CNC stone processing center has the advantages of high precision, high efficiency and flexibility, and is suitable for various complex stone processing needs.

CNC Waterjet Cutter: Waterjet cutters use a high-pressure stream of water mixed with abrasive particles to cut through stone materials. They're ideal for intricate designs and delicate materials.

CNC Milling Machine: While more commonly used for metal and wood, CNC milling machines can also be adapted for stone milling tasks, such as creating sculptures or detailed reliefs.

Key Features of Stone CNC Machines

Precision Control: Stone CNC machines offer precise control over cutting, carving, and engraving operations, ensuring high-quality results.

Automation: CNC machines are automated, meaning they can execute programmed tasks repeatedly with consistent accuracy.

CAD/CAM Integration: These machines often work in tandem with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, allowing users to design complex patterns and then translate them into machine-readable instructions.

Dust and Water Management: Since stone fabrication produces a significant amount of dust and debris, CNC machines are equipped with systems to manage waste, such as dust collectors and water cooling systems.

Applications of Stone CNC Machines

Architectural Stonework: CNC machines are used to create intricate architectural elements like columns, moldings, and facades.

Monument and Memorial Production: They're employed in crafting gravestones, monuments, and memorial plaques with personalized engravings.

Artistic Sculptures: Artists use CNC machines to sculpt stone into intricate artworks and sculptures, taking advantage of the precision and repeatability offered by these tools.

Countertop Fabrication: CNC machines are integral to the process of cutting, shaping, and polishing stone countertops for kitchens and bathrooms.

Advantages of Stone CNC Machines

Efficiency: CNC machines automate tasks that would otherwise be labor-intensive and time-consuming, improving efficiency and reducing production time.

Precision: They offer unparalleled precision and consistency, allowing for intricate designs and complex shapes.

Versatility: Stone CNC machines can work with a variety of stone materials, including granite, marble, limestone, and quartz, making them suitable for a wide range of applications.

Considerations:Initial Investment: Stone CNC machines can be costly to purchase and maintain, so it's essential to consider the upfront investment and ongoing operational expenses.

Training and Skills: Operating CNC machines requires training and expertise in both machine operation and CAD/CAM software usage.

Maintenance: Regular maintenance is crucial to keep CNC machines running smoothly and ensure longevity.

Overall, stone CNC machines play a vital role in the stone fabrication industry, offering precision, efficiency, and versatility for various applications.

How much is the stone CNC machine cost?

The cost of a stone CNC machine can vary significantly depending on several factors such as the machine's size, capabilities, brand, and additional features. Here's a rough estimate of the price range for different types of stone CNC machines:

Entry-Level CNC Routers

Entry-level CNC routers suitable for basic stone carving and engraving tasks can start from around $5,000 to $10,000 USD. These machines may have smaller work areas and limited capabilities compared to higher-end models.

Mid-Range CNC Routers

Mid-range CNC routers with larger work areas, higher spindle power, and more advanced features can range from $10,000 to $50,000 USD. These machines are suitable for medium-scale stone fabrication projects and offer better precision and efficiency.

High-End CNC Routers and Bridge Saws

High-end CNC routers and bridge saws designed for professional stone fabrication shops can cost anywhere from $50,000 to $200,000 or more, depending on their size, capabilities, and brand. These machines are equipped with powerful spindles, advanced automation features, and robust construction to handle heavy-duty cutting, carving, and polishing tasks.

CNC Waterjet Cutters

CNC waterjet cutters are typically more expensive due to their advanced cutting technology. Prices for stone CNC waterjet cutters can range from $100,000 to several hundred thousand dollars, depending on the size, cutting capabilities, and brand.

Custom-Built CNC Machines

Some stone fabrication shops may opt for custom-built CNC machines tailored to their specific requirements. The cost of custom-built machines can vary widely depending on the specifications and complexity of the design.

It's important to note that these are rough estimates, and actual prices may vary based on factors such as geographic location, supplier discounts, and additional services such as installation and training. Additionally, ongoing expenses such as maintenance, tooling, and software should also be considered when budgeting for a stone CNC machine.

What factors affect the stone CNC machine price?

Machine Type and Configuration

The type of stone CNC machine, whether it's a CNC router, CNC bridge saw, CNC waterjet cutter, or CNC milling machine, will significantly impact the price.

The machine's size, configuration (such as the number of axes), and capabilities (such as spindle power and cutting speed) also affect the price. Larger machines with more advanced features tend to cost more.

Brand and Reputation

Established brands with a reputation for quality and reliability often command higher prices for their CNC machines. Customers may be willing to pay a premium for the assurance of superior performance and after-sales support.

Lesser-known or generic brands may offer cheaper alternatives, but buyers should carefully evaluate the quality and reliability of such machines.

Material and Component Quality

The quality of materials used in constructing the CNC machine, including the frame, spindle, linear guides, and electronics, can impact the price. Machines built with high-quality components tend to be more expensive but offer better durability and performance.

Some machines may incorporate premium features such as precision ball screws, servo motors, and advanced control systems, which can contribute to a higher price tag.

Work Area and Capacity

The size of the machine's work area (the area within which it can perform machining operations) influences the price. Machines with larger work areas generally cost more due to the increased material and construction requirements.

CNC machines with higher load capacities and capabilities to handle larger and heavier workpieces may also be priced higher than those with smaller capacities.

Automation and Advanced Features

CNC machines equipped with advanced automation features such as automatic tool changers, tool measurement systems, and material handling systems tend to be more expensive.

Additional features such as coolant systems, dust extraction systems, and integrated CAD/CAM software packages may also contribute to the overall cost.

Accessories and Tooling

The inclusion of accessories and tooling such as cutting tools, collets, vacuum fixtures, and rotary attachments may affect the machine's price. Some suppliers offer bundled packages that include essential accessories, while others may sell them separately.

Support and Services

The level of customer support, warranty coverage, training, and after-sales services provided by the manufacturer or supplier can influence the price. Machines from suppliers that offer comprehensive support and services may come with a higher price but provide added value in terms of technical assistance and maintenance.

Market Demand and Competition

Market demand and competition can also affect the pricing of stone CNC machines. In highly competitive markets with multiple suppliers, prices may be more competitive as companies strive to attract customers.

Conclusion

The blog provides a comprehensive overview of stone CNC machines, covering four main aspects. It begins with an introductory section, "Stone CNC Machines: A Brief Overview," which serves as a primer on these specialized tools. It then delves into the crucial question of cost in "How much is the stone CNC machine cost?" Here, readers can expect to find insights into the pricing range of these machines, along with factors that influence their costs.

Furthermore, the blog explores the multifaceted question of what factors impact the price of stone CNC machines. It outlines several key considerations, including machine size and capacity, automation features, brand reputation, material quality, technical specifications, customization options, and after-sales support services. By understanding these factors, readers gain valuable insights into the intricacies of pricing within this niche market.

Overall, the blog serves as an informative resource for individuals seeking to understand the complexities of stone CNC machine pricing. Whether readers are considering purchasing a machine or simply seeking to expand their knowledge of CNC technology, the information provided offers a solid foundation for informed decision-making.