Blue Elephant has always attached great importance to the customer’s experience with the machine. We continue to update and iterate our products with innovative ideas. In particular, the existing technology is continuously improved and upgraded in detail to optimize the performance of the equipment, so as to bring a better user experience.

New Double-layer Vacuum Adsorption Table

For the previous CNC router, the adsorption table is generally provided with a vacuum suction hole on the table, and a vacuum is applied to generate a negative pressure between the work piece and the work surface, thereby ensuring that the work piece can be firmly fixed on the . However, in the actual use process, the work table is unstable due to the difference in the size and shape of the work piece. Therefore, the work piece is liable to sway during the machining process, which directly affects the machining accuracy of the work piece.

In order to solve this problem, Blue Elephant has improved the traditional vacuum adsorption table. According to the customer’s processing requirements, the machine can be equipped with double-layer vacuum adsorption, and added more partition. The improved adsorption surface of the adsorption table is greatly enhanced, especially for shaped work pieces. After the upgrade of the cnc router with the latest double-layer vacuum adsorption table was put on the market, it was well received by customers.

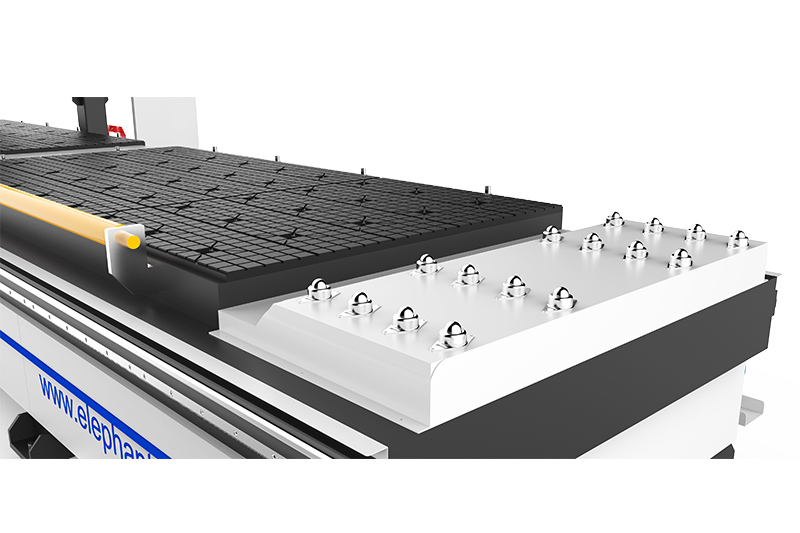

Improved Automatic Feeding System

The automatic loading and unloading system is widely used in the field of CNC machine, especially in the automatic production lines of various industries. In woodworking CNC machine tools, fully automatic panel furniture production lines are the most widely used. However, the traditional automatic loading and unloading system is prone to poor gripping, and the design is unreasonable, resulting in wear of the board or equipment, which greatly reduces the practicability of the automatic feeding system.

The new automatic loading and unloading system modified by Blue Elephant CNC reduces the labor intensity of the operator through the setting of the roller, saves manpower, improves efficiency, prevents table wear and prolongs the service life of the equipment.

In addition, we also upgrades the bed, which Improving the stability of the machine bed and reducing the cost of equipment. Besides that the tool changer has also been upgraded to increase the tool change speed and further improve production efficiency. In a word, a series of upgrades to the equipment from the details make Blue Elephant product quality leading the industry, and widely recognized.