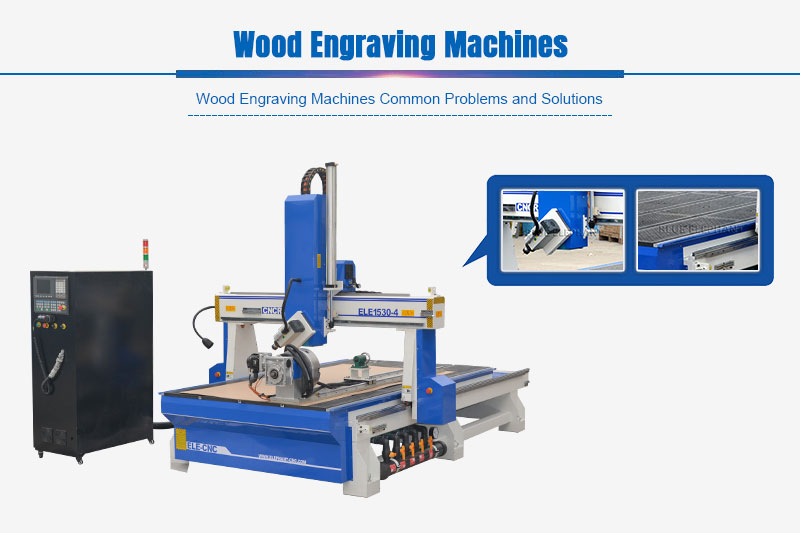

The advent of wood engraving machines has brought tremendous convenience to people, such as saving a lot of engraving time, while improving the engraving efficiency and improving the engraving process, so that many industries benefit from wood engraving machines. At present, wood engraving machine has become one of the necessary CNC machine in various industries. With the widespread use of wood engraving machines, engraving machines are also accompanied by various problems during use. As a professional wood engraving machine manufacturer with decades of experience in woodworking engraving machines, Blue Elephant CNC today brings you to know the common problems and corresponding solutions in the use of wood engraving machines. I hope to bring you help.

Common problem1:The wood engraving machine will break the knife during the processing.

1. The processing program is the instruction of the machine work, including the position command and the speed command, which is the basis of the machine movement. Therefore, whether the machining program is correct and reasonable directly affects whether the tool will break the knife. If the depth of the infeed programmed by the program is too deep, or if the cutting amount is set too much and exceeds the tolerance of the tool, the problem of the tool breaking will occur.

2. The engraving machine is the executor of engraving and the supplier of engraving power. Whether the engraving machine is selected correctly during processing or whether the current state of the engraving machine is normal will become the influencing factor of the broken knife.

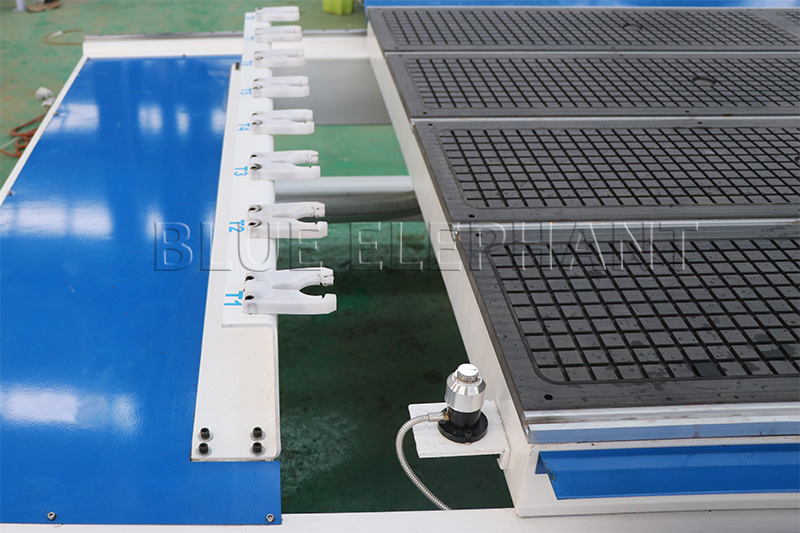

3. The clamping state of the wood engraving machine tool is also an influencing factor of the broken knife, such as the tool clamping is not complete, the radial run out is large, or the tool extension length is too long, the tool and the chuck are dusty, the chuck and the nut are not intact, etc. These factors all will cause broken tools.

4. If these are all right, consider whether the tool has not been replaced for a long time. Because the tool is used for a long time, the tool itself will be greatly reduced in hardness, strength, and sharpness. Therefore, it is required to check the tool for wear and tear, and the worn out should be replaced.

5. The engraving material is the object to be processed. If the material itself is not uniform in hardness or there is impurity on the material, the knife will be broken. In addition, when the high hardness material is engraved for a long time, the cutting edge of the tool may also occur. Moreover, when carving hardwood, if the engraving speed is adjusted too high, there will be a problem of broken knife.

6. Broken knife can also be caused if the work piece is not clamped securely.

7. There is a vibration source around the wood engraving machine that will affect the machining state and cause the knife to be broken. If the voltage is unstable, the working condition will be abnormal and the knife will be broken. Secondly, whether the chip evacuation of the auxiliary equipment of the machine is one of the important factors that cause the broken knife.

8. The skill level of the operator and the proficiency of the operation are also one of the important factors affecting the broken knife.

Common problem2: When the wood engraving machine sets the origin, the main axis is offset forward or to the right and the offset distance is uncertain.

1. The first consideration is that the limit switch is malfunctioning, or that the limit switch has been closed and popped up when the spindle returns to the origin. In this case, we need to check the limit switch, and replace the limit switch if necessary.

2. Secondly, the loosening of the drive line will also cause the phenomenon of spindle movement. In this case, you only need to fix the drive line tightly.

Common problem3: When the wood engraving machine starts to reset, it makes an abnormal sound or always pushes the limit switch.

1. If the spindle can't reach the limit switch, just correct it.

2. The drive line is not in good contact, the drive line should be fixed.

3. The limit switch wire is not connected well, just connect the wire.

4. The limit switch is damaged, just replace it.

Common problem4: Wood engraving machine cannot engrave at the origin.

1. Check whether the file's layout size matches the machine.

2. Check whether there is an offset.

Common problem5: The spindle motor suddenly stopped or slowed down during the work of the wood engraving machine:

1. The working voltage is unstable or overloaded, just add a voltage regulator.

2. Check whether the wire is well-connected and whether the wire ends are disordered.

Common problem6: The spindle only moves in one direction when it starts to move.

1. Check whether the optical coupling line is working properly and whether the lines are in good contact.

2. Check if there is any virtual welding in the motor circuit.

Common problem7: The sending software cannot be opened normally, and the carved objects are deformed.

1. Restall the new system and software.

2. Check whether the X and Y axis screws and screws are loose.

3. The carving knife has problems.

Common problem8: The signal cannot be transmitted.

1. Whether the wood engraving machine parameters and computer settings are correct.

2. Whether the signal cable is connected correctly.

Common problem9: The engraving effect is not ideal.

1. The tool bit is blunt and has some wear and requires grinding.

2. Whether the tool setting in the software matches the actual tool used.

3. Whether to add lubricant when engraving hard materials such as metal, jade, glass, etc.

4. Whether the cutter bar is concentric.

Common problem10: The machine head cannot be reset to origin and the wood engraving machine format is reduced or out of bounds.

1. If the wood engraving machine head cannot be reset to origin, the screw may be misaligned, and the screw needs to be adjusted.

2. The travel switch is damaged.

These are some common problems and solutions that we have summarized about the use of wood engraving machines in the process of use. I hope to help you. Later we will continue to add relevant new content about it. If you want to know about the problems in the use of wood engraving machine, you can leave us a message at any time. We will reply to you as soon as we see it.