2060 ATC CNC Router for Aluminum

2060 ATC CNC Router Carousel Type

2060 larger ATC CNC router machine is designed with HSD aggregate heads, which can do very powerful work. In addition to the typical application of ATC CNC machines, the machine can also be used for milling, boring and drilling.

1. Improving working efficiency: Linear tool change magazine to promote the working efficiency. It manages tool changing automatically in the engraving process, while Multi-head or spindle CNC Machine only can change 2 or 3 or 4 tools;

2. Please notice that all the specifications of the machine can be designed and made according to your actual requirements;

| Model | ELECNC2060ATC |

| X,Y axis travel | 2000x6000mm, option: 1500*3000mm; 2100*3000mm; 2100*4000mm, etc |

| Z axis travel | 200mm, option: 300mm, 400mm, 500mm, 600mm, etc |

| Spindle type | 9.6kw ATC air cooling spindle, ISO30, ER32 |

| Inverter type | 11kw |

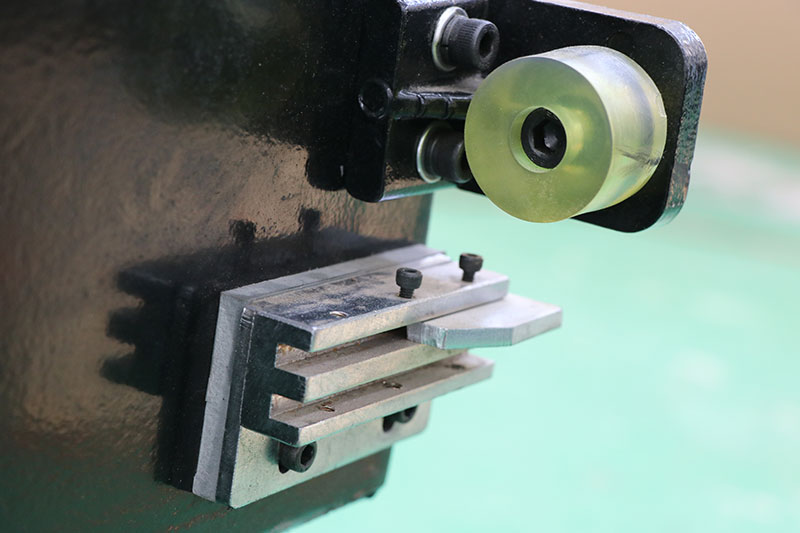

| Drilling bank | Aggregate with C axis |

| Tool magazine | Carousel type auto tool changer Option: linear type auto tool changer |

| Tool holder with collet | ISO30, ER32 collet: φ4, φ6, 1/8, 1/2 |

| Control system | Taiwan SYNTEC controller |

| Driving system | 1kw Japan YASKAWA AC servo driver and 850w AC servo motor, 4 sets. option: 1kw Taiwan Syntec servo |

| Reducer | Japan SHIMPO reducer |

| Machine structure | Heavy duty body with quenching treatment |

| Work table | Aluminum T-slot & vacuum work table |

| Positioning cylinder | 5 pieces (X2, Y3) |

| Linear guide | Taiwan linear guide ( dust proof as option) |

| Transmission | X, Y axis: Taiwan / Germany Helical Rack and Pinion Z axis: Taiwan TBI high precision ball screw |

| Lubrication system | 1.5L automatic lubrication system |

| Tool calibration | Automatic tool sensor calibration |

| Cables | Germany Igus cables with CE, CUL certificate |

| Compatible software | Artcam, Alphcam, Type 3, Ucancam, Aspire, etc |

| Command language | G Code |

| Traveling speed | 80m/min |

| Working speed | 0-25m/min |

| Re-positioning accuracy | ±0.03mm |

| System resolution | ±0.0025mm |

| Working accuracy | ±0.03mm |

| Working air pressure | 0.6MPa |

| Working voltage | 220V 1PH/3PH 50HZ/60HZ 380V 3PH 50HZ/ 60HZ |

| X,Y,Z working area | 2000*6000*300 mm |

| Control system | Taiwan SYNTEC control system |

| Spindle | 9kw Italy HSD air cooling spindle |

| Inverter | 11kw Taiwan DELTA inverter |

| Motor and driver | 850W YASKAWA servo motor and 1kw YASKAWA driver, KOTEC reducer |

| Table surface | T-slot & vacuum working table with 12 areas |

| Table structure | New type thicker and bigger heavy duty welded frame and gantry |

Click for details

HSD aggregate head

Tool sensor

Limit switch

Linear square guide

Click for solution

Click for quotation