Customer information

The Ghanaian customer Krib is a friend of our old customer Jerry. During a business exchange, Jerry talked about our wood CNC router and expressed his appreciation. After hearing this, Krib was very surprised, so he asked Jerry for the contact information of our salesman. After some detailed communication, our salesman recommended the ELECNC-1325 woodworking engraving machine for him according to Krib's processing needs.

Afterwards, he sent Krib the real machine pictures and product parameters of the woodworking machine. After reading it, Krib was very satisfied. He felt that both the appearance and the machine parameters were in line with his requirements. At this time, he was already a little excited, and intends to buy our machine.

But since it was the first time to cooperate, he was still cautious. Then he asked us for the test video of the machine. In addition, he also wanted to get a more realistic and objective user evaluation, so he contacted his friend Jerry again to learn about our company, such as the production capacity, production quality, research and development results, after-sales service, machine life, efficiency, production volume, etc.

After about a week, Krib found us again and said that after consideration and comparison in various aspects, he still appreciates us. He like our product quality, machine configuration and after-sales service very much. He thinks that our ELECNC-1325 woodworking engraving machine was tailor-made for him. So he finally purchased an ELECNC-1325 woodworking engraving machine.

Machine configuration

1. Air-cooling spindle

This CNC woodworking engraving machine adopts the Italian HSD air-cooling spindle, and the spindle speed can reach 18000RPM per minute. The spindle also has extremely high reliability and a variety of power options, so it can meet the diverse processing needs of users. At the same time, the electronic components used in the HSD spindle have been strictly tested, which also ensures the long service life and high machining accuracy of the machine.

2. Spray

Install simple spray, which can cool soft metals, plastics, etc. during processing, and prevent damage to the equipment due to overheating for a long time.

3.Fuling inverter

This woodworking engraving machine is equipped with Le 5.5KW Fuling frequency converter. The inverter has stable performance, rich function combination, high-performance vector control technology, low-speed and large-torque output, good dynamic characteristics, and strong overload capacity.

4. DSP control system

This machine adopts DSP control system, and uses the handle to manually control the movement of the woodworking engraving machine, which greatly saves the space occupied by the equipment. In addition, this DSP handle is more convenient for knife setting, low cost, easy to learn and operate.

5. Stepper motor

This machine adopts 450B stepping motor. Compared with ordinary motors, this motor has the simple structure, convenient control, high reliability, high precision and low cost.

Advantages

-

High cost performance: It has low cost, simple operation, multiple functions and convenient maintenance, and is deeply loved by users at home and abroad.

-

Wide range of applications: It is widely used in various industries such as furniture, advertising, handicrafts, molds, construction, printing and packaging, decoration, etc.

-

Wide range of processing materials: It can process most non-metallic materials such as acrylic, PVC board, two-color board, wood board, density board, fireproof board, rubber board and so on.

-

High degree of automation: Compared with traditional processing methods, its processing efficiency is increased by 50%.

-

Operational safety: It can automatically complete the overall cutting and engraving process. Therefore, the operator does not have to cut the wood board with a hand tool, nor does it have to be close to the cutting position. This makes processing safer and more precise.

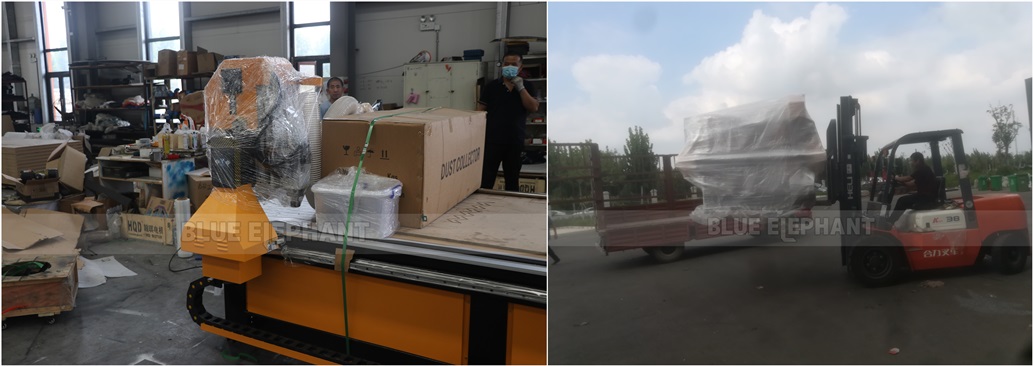

Packaging and loading

The machine has been well packed and carefully loaded to a truck. And soon it will arrive at its destination and start its mission. We hope our customer can give full play of this CNC machine and get more benefits from it.

CNC wood router has many advantages and functions. If you want to get more information about this type of machine, such as the type, processing effect, transportation, packaging, after-sales service and customer feedback, please feel free to contact us. We promise to give you the most timely and high-quality service, and look forward to your patronage.