Brief Introduction of Economical 4 Axis 4+1 CNC Bridge Saw

Innovation in the field of CNC machine tools in the contemporary industrial world is changing with each passing day. Jinan Blue Elephant CNC Machinery Co., Ltd. recently launched an eye-catching new product: a economical 4 axis 4+1 CNC bridge saw with a spindle.

Another highlight of this cutting machine is the newly added water-cooled spindle. The addition of a spindle enables the machine to perform drilling, engraving and other processing on the workpiece while cutting, greatly improving processing efficiency and flexibility. This means that users do not need to frequently transfer workpieces between different equipment, but only need to complete multiple processing operations on the same machine, greatly saving time and costs.

In addition to functional innovation, this economical 4 axis 4+1 CNC bridge saw from Jinan Blue Elephant CNC also has convincing performance in terms of performance and stability. The use of advanced control systems and high-precision cutting heads ensures the accuracy and stability of processing. At the same time, the intelligent operation interface and convenient operation process enable users to get started easily and quickly put into production, thereby better meeting market demand.

For many industries, such a powerful and stable 4 axis 4+1 CNC bridge saw with spindle will become a powerful tool to improve production efficiency and expand processing scope. Whether in the fields of metal processing, decoration technology, or advertising production, everyone will benefit from the application of this innovative product.

Features of Economical 4 Axis 4+1 CNC Bridge Saw

1. Blue Elephant multifunctional 4 axis 4+1 CNC stone bridge cutting saw machine adopts infrared knife setting, microcomputer control, and hydraulic transmission technology. So it has the characteristics of fast cutting speed and high cutting accuracy.

2. The economical 4+1 4-axis CNC bridge saw an achieve 0° and 45°stone cutting. However, unlike the 5 axis CNC bridge saw, the 4+1 CNC bridge saw cannot achieve cutting at any angle.

3. Using a high-speed water cooling spindle, U-shaped, L-shaped and other corner cutting can be completed at one time. It makes up for the defect of the saw blade not cutting corners properly.

4. The 4 axis CNC bridge saw machine can cut various special-shaped pot holes at high speed. The Taichung basin and under-counter basin are directly formed in one go, effectively solving the pain points in countertop processing. Greatly improve work efficiency. Reduce labor costs.

Processing Materials of Economical 4 Axis 4+1 CNC Bridge Saw

The 4+1 4-axis CNC bridge saws are primarily used for cutting stone and similar materials. They can cut various types of stone, such as marble, granite, sandstone, limestone, natural stones, artificial stones, and so on. In addition to stone, some bridge saws can also be used to cut similar materials, such as concrete, ceramic tiles, etc.

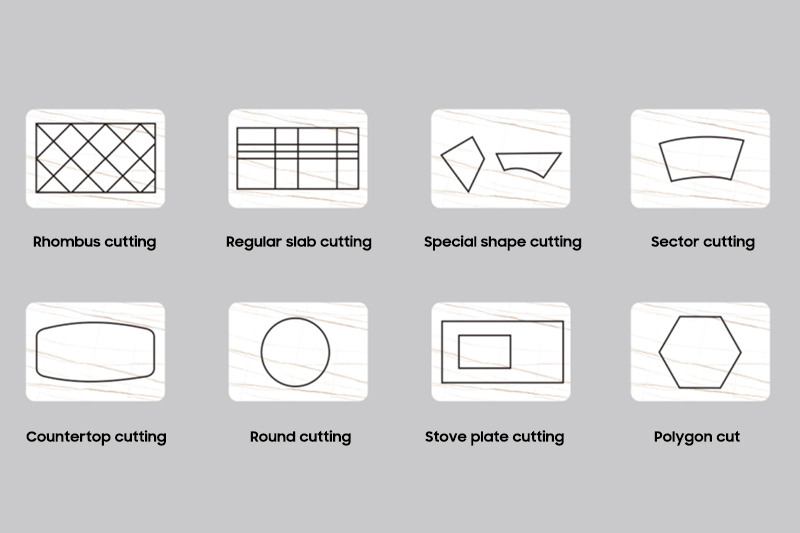

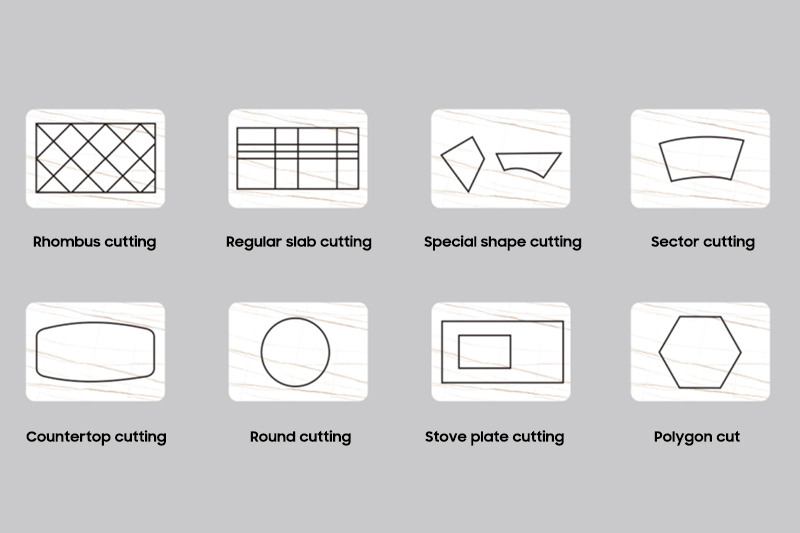

Functions of Economical 4 Axis 4+1 CNC Bridge Saw

Cross cutting, vertical cutting, any reverse bevel cutting, rhombus cutting, horse belly cutting, circular cutting, oval cutting, L-shaped countertop cutting, 45° chamfering on four sides, under-counter basin cutting, Taichung basin cutting, etc.

Advantages of Economical 4 Axis 4+1 CNC Bridge Saw

1. This 4 axis CNC bridge saw is equipped with an extra flexible spindle, which is flexible and has multiple functions, and can achieve complex stone processing.

2. The marble CNC 4 axis bridge saw machine is very simple to operate. It is very smart and can be easily mastered by novices.

3. Blue Elephant 4 axis bridge saw with spindle can realize automatic measurement and intelligent import, which makes the stone cutting and charmfering be more accurate.

4. Users can connect to the Internet and control the 4+1 granite CNC bridge saw remotely. It's more convenient to do stone processing works even not at home or shop.

5. The quartz stone 4 axis CNC bridge saw machine has the automatic suction cup, moving the board to avoid saw marks.

6. With the photographing function, it can complete typesetting and pattern cutting on demand.

Working Video of Economical 4 Axis 4+1 CNC Bridge Saw

Machine appearance - 0:04- 0:18

Wash basin cutting - 0:26 - 0:40

Trimming and Chamfering - 0:44 - 1:05

Drilling - 1:08 -1:15

45° cutting - 1:16 - 1:30

This video shows the appearance and working process of the Blue Elephant economical 4+1 CNC bridge saw machine. It will show you how to perform 45° cutting, wash basin cutting, drilling, trimming and chamfering.

FAQ of Economical 4 Axis 4+1 CNC Bridge Saw

1. What is the maximum cutting thickness of the economical 4 axis 4+1 CNC bridge saw blade? ----80mm.

2. Is the saw blade speed adjustable? ----Yes. The saw blade speed can be set in the system, and the maximum rotation speed can reach to 3300rpm.

3. If I want to use the spindle to work, does the saw blade need to be replaced? ----Unnecessary. The saw blade and spindle work alternately without affecting each other.

4. Does this 4 axis CNC bridge saw change tools manually or automatically? ----Manually. (① The system does not support the automatic tool changing. ② The spindle is used to cut pot holes. There is no need to change the tool. One knife is enough.)

5. Can the bridge saw be edged and polished? ---- No, the bridge cutting saw can cut large stone slabs into small slabs as required. It is the

quartz stone CNC machining center that is responsible for edge grinding and polishing.

6. Can I add a camera and a material moving device? ---- No, the system does not support it. If you want to add a camera or a material moving device, you can choose another 4 axis bridge saw machine: heavy-duty 4 axis 4+1 CNC bridge saw.

7. The control system on the computer can be directly connected to the Internet. If there are problems later, can it be done remotely? ---- Of course. We will provide you with remote support.

Conclusion

In general, Jinan Blue Elephant CNC newly launched 4+1 4-axis CNC bridge cutting machine with spindle is not only a high-end equipment, but also a technological innovation and breakthrough in the field of stone processing industrial. Its emergence will greatly promote the development of CNC cutting technology, bring more possibilities to industrial production, and will also become a "dark horse" in the industry, leading the industry to develop in a more efficient and smarter direction.