We all know that every CNC machine is composed of various CNC machine kits, and woodworking CNC machines are the same. The quality and service life of cnc router kit directly affect the processing quality and efficiency of cnc router. And that's why the CNC router kit plays an unreasonable role on the woodworking CNC machine running efficiently. The choice of a CNC router kit not only affect the price, service life, and operating efficiency of the woodworking machine, but also directly affects the processing performance of the entire equipment. therefore, in order to use the CNC router machine better, we must pay attention to the choice of CNC router kit.

Today, Blue Elephant will take you to learn about the types of the CNC router kit, as well as their respective advantages and disadvantages and applicable users. Promise me not to miss it. In this article, we will introduce the common CNC router kits such as spindle, motor, control system, guild rail, working table, and bed frame. We also introduce the vulnerable CNC router kit like tool bit. Besides that, there are other cnc router kits like the tool magazine, reducer, the screw of the wood engraving machine. It not only includes the role and function introduction of CNC router kit. It also includes the types of CNC router kit and the advantages and disadvantages of different types of CNC router kit. Our goal is to let customers know more about the CNC router kit, operate the CNC wood router better, and choose the CNC woodworking machine that is more suitable for our processing needs while understanding the CNC router kit.

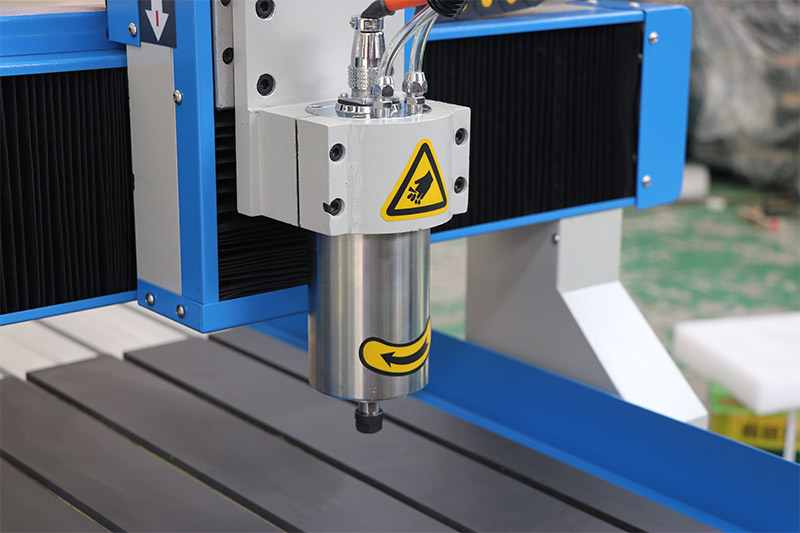

The spindle is an important component of the CNC router kit of woodworking engraving machine, and its performance has a vital influence on the performance of the wood CNC router. The choice of the spindle not only affects the accuracy and quality of the engraving machine but also directly affects the work efficiency of the entire woodworking engraving machine. According to different cooling methods, common spindles on the market can be divided into air-cooled spindles and water-cooled spindles.

The air cooling spindle uses a fan to dissipate heat. It does not need to be connected to a water tank, a water pipe, or a water pump, and can be used directly by connecting the invert. Therefore, it has the advantages of low cost, convenient use, and simple operation. However, it is noisy, the cooling effect, and the effect is not as good as the water-cooled spindle.

The water cooling spindle adopts water circulation to cool the heat generated by the spindle after high-speed rotation. And this cooling method has the advantages of good cooling effect, low noise, long service life, and high precision. The disadvantage is that it is inconvenient to use, especially in cold places in the north or where water is lacking.

As the one of the core CNC router kit, the motor also plays the important role in the wood working engraving. We all know that the motor directly affects the engraving speed of the engraving machine. And processing speed directly affects processing efficiency. Therefore, the choice of the motor accordingly affects the user's economic benefits. In the wood CNC router industry, there are mainly two types of drive motors such as servo motor and stepper motor.

Servo motor refers to the engine that controls the operation of mechanical components in the servo system and is an auxiliary motor indirect speed change device. In addition to speed and torque control, servo motors can also perform precise, fast, and stable position control. In addition, this servo motor has the advantages of stable operation, good control ability, fast response, high sensitivity, and high precision. Therefore, it is suitable for applications that require high efficiency, high speed, high response, and high reliability.

The stepper motor open-loop control method is simple and easy to implement. And the overall price is lower. Therefore, it has the advantages of low cost and convenient use. But in this control mode, the real-time position of the rotor has no feedback effect on the entire control system. Therefore, stepper motors are not suitable for applications in some fields that require high precision, high-speed operation, and fast response capabilities.

As a member of the CNC router kit, guild rail is mainly an important part of the transmission system. And the guide rail plays the role of transmission and support in the CNC router machine. Choosing the appropriate guide rail will make the operation of the CNC wood machine more stable and smooth. The guide rails on the market are mainly divided into round rails and square rails.

The round rail is a cylindrical linear rail. It has the advantages of high carrying capacity, low cost, short production cycle, and easy installation. However, the circular rail needs to be supported in limited places, so the rigidity is relatively poor and the single-precision is average. Therefore, it is suitable for processing fields that require less precision.

The square rail has high positioning accuracy, good reproduction, and the friction coefficient is particularly small. And the gap between the static friction force and the dynamic friction force is very small. When the micro feed is small, there will be no slipping phenomenon, and the resolution is good, so it can be achieved positioning accuracy of a high level. Low friction resistance can maintain accuracy for a long time. In addition, because the square rail can withstand high load capacity in four directions, it can simultaneously bear radial, reverse radial, and lateral loads, and maintain walking accuracy. The square rail is suitable for high-speed and high precision applications.

As we all know, the control system is the brain of the CNC router. And as the one of the most important CNC router kit, the operation of the CNC router is closely related to its control system. The control system of CNC wood router on the market can be roughly divided into three categories such as computer control, handle control, and integrated machine control.

Computer control is to control the walking path of the engraving machine's XYZ axis and the rotation of the spindle motor by installing a control card on the PCI slot of the computer motherboard and installing a driver on the computer. With this control method, the operator can preview the processing effect, can see the processing track at any time, and can correct it in time if the program loading error. Therefore, it has many features like a user-friendly interface, simple and convenient operation, complete functions, and high program compatibility. And all kinds of engraving CAM software can be imported. The disadvantage is that you need to configure a computer separately, but fortunately, the computer configuration requirements are extremely low. For customers with a small budget, you can configure second-hand obsolete computers.

Handle control is a control method that can be used to control the movement of the CNC wood router. The biggest advantage is that it saves space and does not require a computer. It greatly reduces the space occupied by the equipment, and it is more convenient to set the knife. The disadvantage is that the operation is relatively troublesome. After all, all the functions are collected on one control panel. If you are not skilled, it is easy to press the wrong function key. What’s more, the disadvantage is that there is no preview and other functions, and the interface is not as intuitive as the computer.

This control method adopts an independent integrated design, adopts integrated control of industrial computers, PLC, and so on. It has rich interfaces and complete functions and can realize multi-axis control and automatic tool change. The disadvantage is that the price is higher and the operation is more inclined to CNC machine tools. It is a bit difficult for some customers to operate. This control system is mainly used for high-end CNC machines, machining centers, and some mold machine wood engraving machines, etc.

The bed frame is the most basic configuration of CNC router kit. And as the one of the basic CNC router kit, the first requirement for the bed is to be stable. The stability of the bed directly affects the machining accuracy and quality of the machine. Therefore, the bed of the CNC engraving machine must be firm and not deformed, otherwise, the CNC engraving machine will sway when engraving the plate, causing the head to not follow the prescribed path, which ultimately affects the processing quality of the machine.

Commonly used in the field of CNC engraving machine are T-shaped bed and square tube bed. Both are structurally stable and can achieve the desired processing results for customers. In comparison, the T-bed is structurally stronger and has a longer service life. Frame bed, the purchase cost is relatively low, users with limited budget can consider this bed. It is necessary to remind everyone that for the convenience of transportation, Blue Elephant can provide users with a split bed, which will facilitate the transportation of the machine without affecting the stability of the bed. Therefore, it is very popular with customers.

As we all know that working table is also a basic member of CNC router kit. And the working table plays a bearing role on the workpiece. Therefore, the table surface also indirectly affects the final processing accuracy and processing quality. There are two kinds of working tables in the wood engraving machine industry which are chosen more common tables and vacuum adsorption tables.

The common aluminum T-slot working table fixed materials by fixtures. A layer of aluminum profiles with T-slots is placed on the bottom of the table, and a layer of PVC is placed on the table. This table is fixed by fixtures, which is suitable for irregular material shapes which is not easy to fix by vacuum adsorption or the processing technology is a relief, hollowing, cutting, and other processes.

The vacuum adsorption table is composed of a vacuum pump and high-quality bakelite, which can be divided into six-zone and eight-zone vacuum adsorption, which can further enhance the adsorption function. We just need to put the workpiece on the vacuum adsorption table, turn on the vacuum pump, open the control valve, and directly suck the workpiece on the table. And there is no need to clamp it with a fixture. Its advantage is that even if it is an irregular plate, it can still be tightly fixed on the table of the CNC router. and there will be no vibration during the engraving process that will affect the engraving effect. Especially for thinner and lighter or irregular plates, the material is fixed more firmly by a vacuum adsorption table. If this kind of plate is fixed by fixtures, it may cause small-displacement due to machine vibration during the engraving process, which will affect the accuracy of engraving, and this problem will not exist in the vacuum adsorption table. However, if the board is relatively heavy, such a board itself is heavy enough, and it is a bit laborious to absorb, and only need to be fixed by a jig to ensure that no displacement will affect the accuracy of engraving.

Unlike other CNC router kit, the tool changer magazine is not the basic configuration of the woodworking engraving machine. This CNC router kit is selectively installed on the router machine according to the user's processing needs. The automatic tool changer engraving machine is favored by more and more users due to its advantages such as fast tool change speed and high production efficiency. According to the tool change method, it can be divided into two types: such as lineartool change and disc tool change.

The number of tool magazines in the line-up tool magazine can be customized according to the user's specific processing requirements. The position of the inline tool magazine can be placed under the gantry or behind the bed. This tool change method has the advantages of low cost and fast tool change speed. In particular, the straight-line tool magazine placed under the gantry greatly saves the time of tool change, improves the processing efficiency, reduces the wear on the guide rails, and prolongs the service life of the machine accordingly. The position placed under the gantry is the most reasonable, because this way the tool change speed is fast, the wear on the guide rail is small, saving time, and there is no need to run to the rear every time the tool is changed.

The number of tools in the disctool magazine can be customized according to the user's processing requirements. The tool magazine can be placed next to the spindle or the side of the gantry. This rotary tool change method has the characteristics of faster tool change speed, so the production efficiency is higher. In addition, this tool change method makes the machine run more stable, which can ensure higher processing accuracy and higher processing quality.

The tool is the most common CNC router kit of wood engraving machines and it is also the one of the wearing parts. In woodworking CNC machine engraving, many details can affect the quality, accuracy, and appearance of the engraving, especially the choice of tools. And the tool is a common vulnerable CNC router kit. Choosing the right tool according to different processing materials and different engraving techniques is an important factor to ensure fast and efficient production. So what kinds of CNC woodworking machine tools are divided into? What kind of carving is suitable for each tool? The following are several tool types commonly used in the woodworking CNC router industry.

A flat-bottomed sharp knife is a common wood CNC router tool. This tool is suitable for small precision relief processing, and the carved product has smooth and exquisite edges. It takes more time to make large relief carvings.

Straight knives are also a relatively common one, which is often used to engrave large characters. The edge of the material cut by it is straight, which is generally used for cutting PVC and acrylic.

The milling cutter is the most common tool in woodworking engraving machine processing. Milling cutters are divided into many types according to their shapes. For example, the double-edged spiral milling cutter used when cutting acrylic and MDF, and the single-edged spiral ball-end milling cutter for large-scale deep relief processing of cork, MDF, solid wood, acrylic, and other materials. The prismatic milling cutter used when making high-density boards, solid wood doors, and furniture. Of course, many tool manufacturers will also make special tools according to the special requirements of many customers, such as large chip-removing spiral milling cutters that are more suitable for cutting density boards and chip removal. The round bottom cutter is more suitable for precision small relief processing.

The screw is the most commonly used CNC router kit of transmission element in tool machinery and precision machinery. Its main function is to convert rotary motion into linear motion or convert torque into axial repetitive force. And it has both high precision, reversibility, and high efficiency. Ball screws and sliding screws are the two most common types of screws in mechanical equipment. The ball screw has fast speed, good accuracy, stable operation, low resistance, and long life. And the accuracy and efficiency of the sliding screw are a little bit worse than that of the ball screw. Besides that, the heating of the sliding screw is relatively large, which requires a long time to cool. That is why it can result in a short service life.

The function of the lubrication system is to deliver a certain amount of clean lubricating oil to the surface of the relative moving parts to achieve liquid friction. It can also reduce friction resistance, and reduce the wear of mechanical parts. That is to say, this CNC router kit can realize the function of cleaning and cooling the surface of the part.

According to the different lubrication methods, it can be divided into automatic lubrication systems and manual lubrication systems. The automatic lubrication system adopts centralized control and automatic lubrication. And it has the features of regular and quantitative, energy-saving, and fuel-saving. It can also effectively reduce the wear and tear of the machine and prolong the service life. The manual lubricating oil pump is small in size. And it is easy to install and operate. Besides that, it is equipped with a non-reverse device, and it can avoid the phenomenon of oil backflow.

The function of the reducer is to reduce the speed and increase the torque accordingly, improve the performance of the machine, and extend the service life of the machine. Both belts and reducers can achieve the above functions. The use of a belt as a speed reducer has the advantage of low cost. However, it is easy to wear after a long time of use and needs to be replaced frequently. As one of the optional CNC router kit, the reducer has the characteristics of higher accuracy, long life, and maintenance-free, which is deeply loved by customers. In addition to the various CNC router kits mentioned above, there are some optional parts. For example, the automatic loading and unloading platform is used to improve the efficiency of loading and unloading; the row drill is used to punch holes, and the press roller is used to make the plate more firmly fixed. In addition, it also includes a rotary device for machining cylindrical workpieces; the oscillating cutter head used to process soft materials such as cloth, etc. These are CNC router kits used in woodworking engraving machines.

In addition to the different type of CNC router kit/part we mentioned above, the CNC router kit also include positioning cylinders, gantry, lead screws, loading and unloading platforms, and pressing rollers. No matter which CNC router kit you want to know, you can leave us a message.

We all know that the CNC router is developed and designed by mechanical engineers according to the user's processing requirements, and then assembled by various CNC router kits. The selection and assembly of various CNC machine kit is also very important. A variety of different CNC router kits can be assembled reasonably to achieve the best compatibility so that the CNC machine can exert its maximum use-value.

These are our relevant introductions about the CNC router kit. Different CNC router kit plays an irreplaceable role in the operation of the entire CNC machine. Therefore, we have to work hard on the choice of CNC router kit. We must start from our own processing needs, consider budget, processing effect, processing efficiency, and other factors to comprehensively choose a CNC router kit.

BLUE ELEPHANT has decades of experience in the production of CNC router machines. In the selection of CNC router kit, we provide customers with various configurations of CNC routers to meet diverse user needs. Most of the CNC router kit vendors we cooperate with are manufacturers of well-known international brands. The quality is very guaranteed. The quality of the CNC router kit not only can ensure high processing quality. And it can also ensure that the CNC router has a long service life. If you are a beginner in the woodworking industry and do not know how to choose a CNC router or CNC router kit, you can contact us at any time. Our professional team can answer any questions about CNC router for you.