The cabinet refers to the platform for storing kitchen utensils. It consists of five major parts, cabinet body, cabinet doors, cabinet hardware, countertops, and electrical appliances. With the popularity and demand expansion of cabinet production, a whole cabinet customization boom has been set off. More and more customers need cabinet customization services. So how to get a suitable cabinet solution? Below, I will provide you with the best two cabinet solutions to make money.

Cabinet Production Process

First of all, we need to know that cabinet production mainly includes two parts - one is cabinet body making and the other is cabinet door making. The production processes of the two are generally similar, basically including disassembly, cutting, edge banding, and drilling. But there are still several slight differences. Below I will expand in turn and explain separately.

Cabinet body making

1. The QR code will be attached to the material sent by the cabinet manufacturer, which contains the specific cabinet making information. Then the machine will scan this QR code to ensure that the subsequent processing and design are correct.

2. Let’s start cutting. The large board is usually the particle board or medium density board. And the board size is 2440mm x 1220mm or 2800mm x 1300mm. The cabinet cutting equipment used is often a CNC panel saw, which can be connected with CNC software to realize intelligent cutting process. Small cabinet manufacturers generally use sliding table saw to save cabinet making costs. Many cabinet manufacturers think that the back panels of floor cabinets is finished after cutting. That’s wrong! Material cutting is only the first step. The board will continue to be processed with other equipment.

3. The bottom plates, side plates, and braces all need to be slotted. The slotting positions of the side panels and the bottom panels are a fixed value from the edge of the panel. And the slotting equipment is generally a sliding table saw. Because the sliding table saw has fast slotting speed and can open thousands of panels a day. It is economical and enough to meet the production capacity of the factory. In addition, for better one-time processing, the slotting saw teeth has the same width as the thickness of the back plate.

4. Almost all cabinet parts need to be edge banded (except for the back panel). And due to the improved workmanship quality, all four sides are now banded. There are two main types of edge banding. One is cabinet around edge- usually 0.45mm plastic edge of the same color as the cabinet. Another is an anti-collision edge, which is 2mm plastic edge. Therefore, three sides where each panel will touch the door will be sealed with cabinet around edge. While the last side is sealed with anti-collision side.

5. Drilling is the most error-prone and most critical process. Because it involves all the connections between the various boards. Besides, drilling holes are divided into structural holes and system holes. Structural holes refer to the holes that do not need to be connected with other holes and are only found on the side panels. While system holes are the holes that each panel needs to be connected to other panels, and all panels (except the back panel) have. The system holes are mainly used to install eccentric parts, screws, tenons, etc. to connect other parts. The structural holes are mainly used to place laminate supports, guide rails, etc. The main drilling cabinet equipment are row drilling machines and CNC six-sided drilling machines.

Cabinet Door Production Process

1. There are many kinds of materials and colors for the cabinet door panels. And they are usually produced according to custom cabinet orders. The equipment mainly includes CNC panel saws and manual sliding table saws.

2. The purpose of cabinet door slotting is to install the aluminum buckle handle.

3. Generally, the materials to be banded are melamine, fireproof board, crystal board, etc. The edge to be banded is generally the same color as the door panel with 2mm thickness. Also, in order to improve the quality, it adopts aluminum edge banding. And the equipment is mainly an automatic edge banding machine.

4. The drilling hole here is a door hinge hole. In order to reduce the error rate, it often leaves to the dealer.

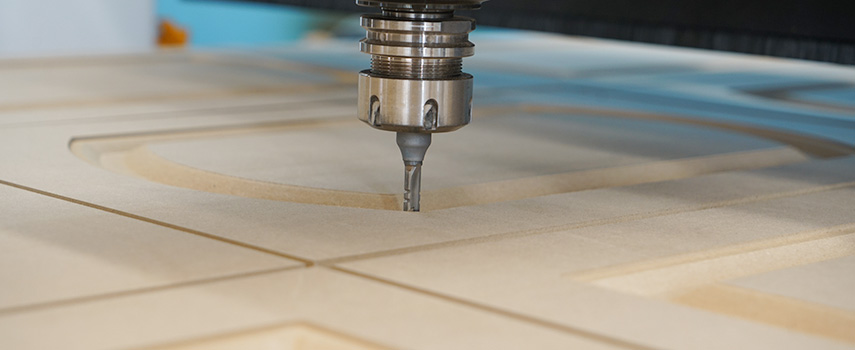

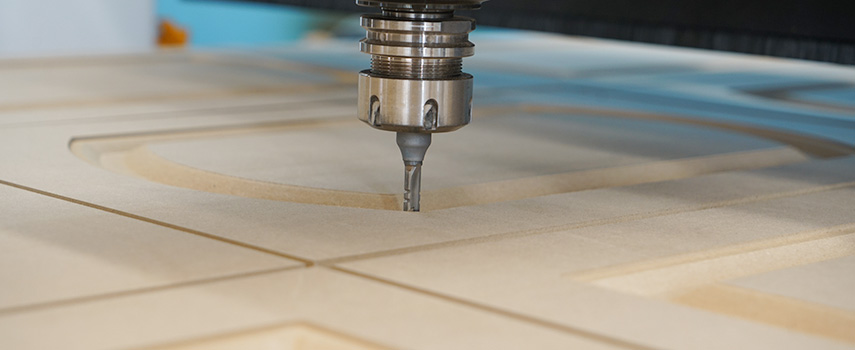

5. Gong grooving is for making cabinet door patterns. The processing equipment is mainly CNC machining center.

6.The steps of blistering are very simple. First, polish the cabinet door. Then spray glue and put the door panel into the blister machine. Last, carry out the blistering machine- vacuum pressing machine to process.

7.The process of baking paint is quite complicated and it is mainly made by hand. So, if you want to spray high-quality cabinet doors, you must have more experience and technology.

Cabinet Solutions

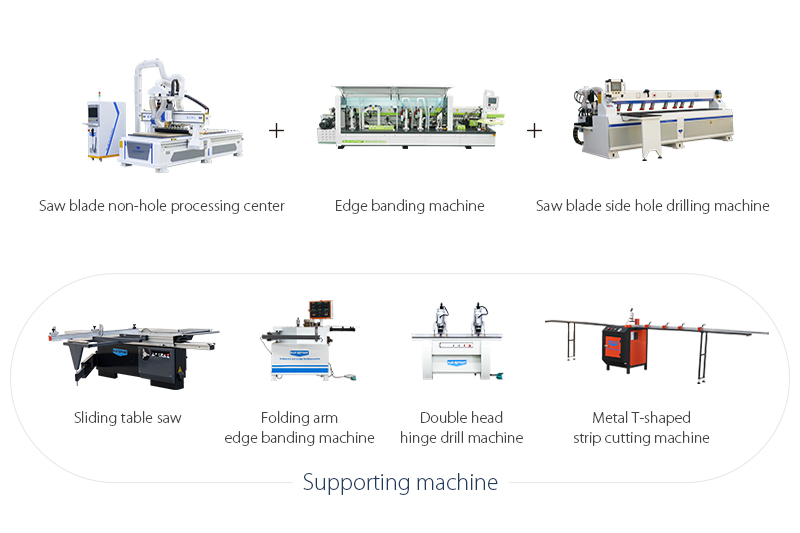

TOP 1 Economical cabinet solution

Blue Elephant's economical cabinet making solution is based on the actual processing needs of customers and processional experience of many cabinet manufacturers. And finally produce a cost-effective custom cabinet production line through resource integration. This entry-level cabinet solution can not only realize the cabinet production, but also the best choice for small and medium cabinet manufacturers.

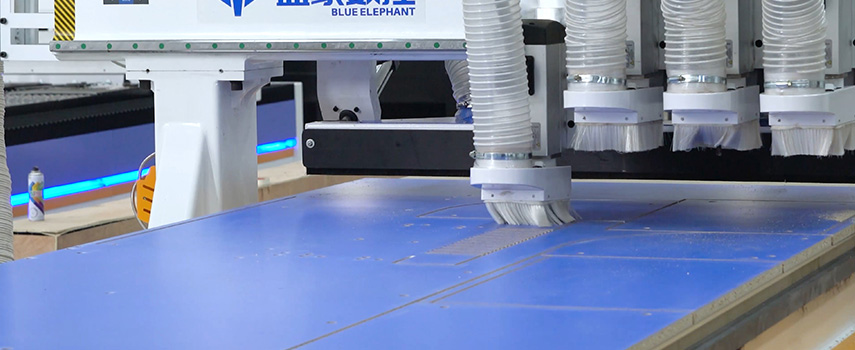

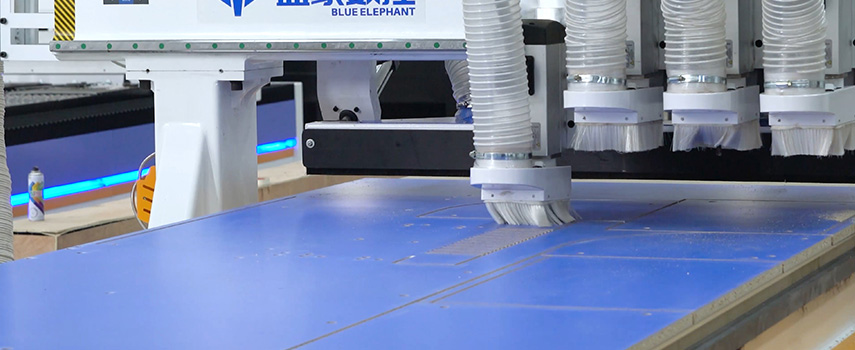

CNC cutting center

CNC control, single spindle to multi-spindle optional, used for panel cutting, drilling, milling and grooving.

The 3 axis nesting CNC machine is equipped with three pneumatic tool change spindles - cutting spindle, slotting spindle, and drilling spindle. In addition, the CNC software equipped with this cabinet cutting equipment can realize the online 3D cabinet design, optimize the disassembly, save the panels, and achieve higher efficiency.

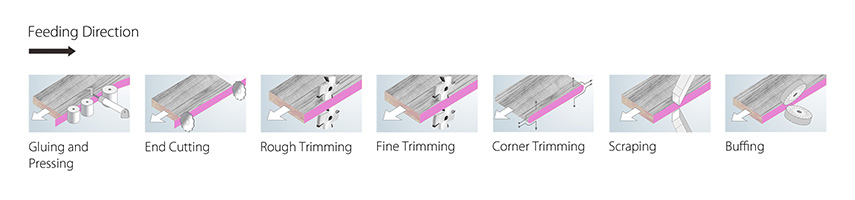

Edge banding center

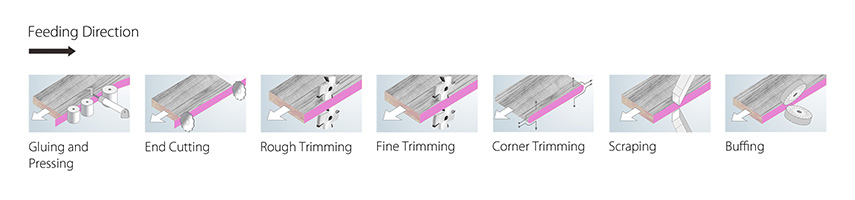

The fully automatic edge banding machine can completely solve the problems of manual edge banding such as glue leakage, poor adhesion, and unsightly appearance. Moreover, it can realize automatic control, linear edge banding, end trimming, rough trimming, fine trimming, scraping, polishing, and other treatments.

CNC drilling center

The single-row CNC drilling machine is a drilling equipment specially developed and designed for side holes. It can realize numerical control control and rapid positioning.

Cabinet sample

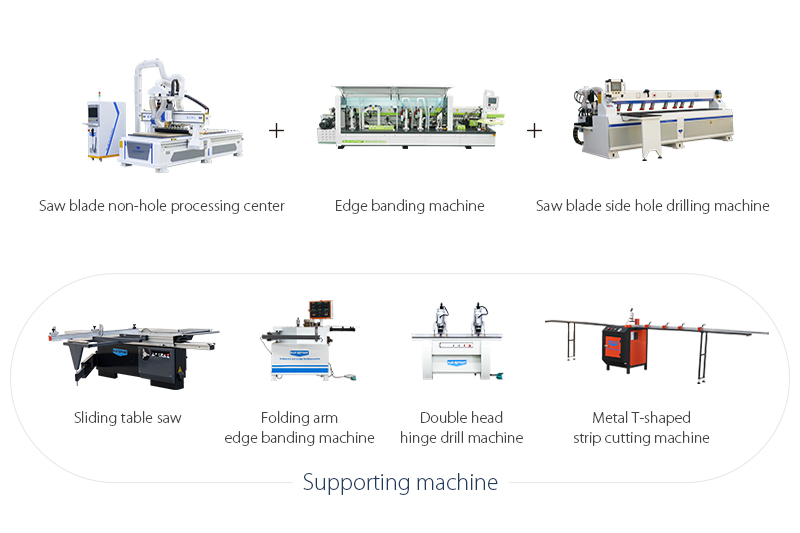

TOP 2 Professional cabinet solution

The professional cabinet production line is also called the compound cabinet production line, which is a non-porous process cabinet production solution. It is mainly composed of three kinds of cabinet equipment: non-porous processing center, saw blade side hole drilling machine, and automatic edge banding machine. It can be used for the production and processing of panel furniture, cabinets, wardrobes, children's furniture, and other cabinets. To meet the needs of cabinet manufacturers for non-porous cabinet (using invisible connectors) and panel cabinet (using two-in-one and three-in-one connectors). Realizing mass custom cabinet production and reducing cabinet production costs. It is the most perfect cabinet solution for custom cabinet production industry.

Non-porous process machining center

The non-porous process nesting CNC machine with saw blade is mainly used for cabinet design. It can not only make installation grooves for various invisible links, but also process the installation holes of 2-in-1 and 3-in-1 connectors. At the same time, it can also realize quickly drilling, grooving,cutting, and loading.

Features:1. Equipped with a high-power ATC spindle, a large-capacity servo tool magazine, and a device for sawing, milling, and slotting, it is suitable for diversified and complex product processing.

2. The 7-zone vacuum table has good adsorption force and avoids running boards during processing.

3. 12 linear tool changers saves tool change time and has very high efficiency.

4. It has a wide range of uses, and can be used for cutting, drilling, cutting, chamfering, and carving at one time.

5. With simple operation, it is especially suitable for cabinet customization.

Fully automatic edge bander

Fully automatic edge banding machine is suitable for panel furniture, custom cabinet, cabinet wardrobe, office cabinet, solid wood cabinet, tables, chairs, doors, windows, and other wood products. It is fitful for the processing of various boards such as density boards, ecological boards, multi-layer boards, particle boards, straight solid wood boards, and aluminum honeycomb boards.

Features:

Features:1. Gluing: the cylinder controls the opening and closing of the glue door. So the glue quantity is stable, and the glue thickness is uniform.

2. End trimming: cut off the redundant edge banding at both ends of the plate stably.

3. Rough trimming: cut the excess edge strips with a six-edged alloy flat knife.

4. Fine trimming: round corners with R knife, which is more beautiful.

5. Tracking trimming: the four corners are trimmed into small arcs, which is more smooth. And the self-designed tracking action and air path make the profiling chamfering more stable.

6. Scraping: the superhard alloy R knife scrapes the fine lines of the edge strips to make them smooth.

7. Polishing: the cloth wheel quickly polishes the edge, making it much smoother and more beautiful.

Saw blade side hole drilling machine

This CNC drilling machine is suitable for various cabinet design. It can complete three-in-one side holes, wooden pin holes, blind holes, fixed slots, through slots, etc.

Features:1. The customized control system has good stability and high precision.

2. American Banner laser probe with high accuracy.

3. The customized limit has high safety.

4. High-power spindle and diamond saw blade has fast speed and high accuracy.

Customer cabinet making case

Cabinet making video

5 Famous Cabinet Manufacturers

Blue Elephant CNC seamlessly connects the four workstations of material cutting, edge banding, drilling, and sorting through robots. It realizes the intelligent assembly line processing of workpieces from material cutting to sorting, greatly reducing labor costs and error rates. In addtion, it also shortens the production cycle time and improves production efficiency and capacity. Therefore, it has gained the trust and choice of hundreds of cabinet manufacturers. The following are the brief introductions of the five well-known cabinet brands and the display of cabinet samples that Blue Elephant cooperates with.

1. OPPEIN

OPPEIN took the lead in introducing "integrated kitchen" into China, creating a precedent for industrialized modern cabinets in China, and is known as the advocate of China's "kitchen revolution" and the leader of integrated cabinets. After more than ten years of development, OPPEIN has already established the leading position in China's cabinet industry. Covering an area of 300,000 square meters, it has become the largest cabinet manufacturing center in Asia.

2. Gold Home

Gold Home is a professional provider of high-end overall kitchen cabinets in China, specializing in the research and development, design, production, sales, installation, and after-sales service of overall kitchen cabinets. Focusing on kitchen cabinets for 19 years, it redefines the standard of professional kitchen cabinets in China. With 9 professional advantages and 10 years of quality assurance, it has been the preferred kitchen cabinet brand of China's top 500 real estate for 6 years!

3. ZBOM

Founded in 1998, ZBOM is one of the early pioneers in China's kitchen cabinet industry. Now, ZBOM focuses on the R&D, production, and sales of whole house custom furniture. With one of the few large-scale manufacturing bases and the advantages of customized design and service, it provides overall solutions from kitchen to whole house for hundreds of millions of families around the world.

4. Piano

Piano is a company mainly engaged in the research and development, production, and sales of customized cabinets and whole house customization. In 2002, Piano took the lead in introducing French style to China, setting off a new trend of life of "tasteful kitchen". Up to now, it has become a first-class cabinet manufacturing base in Asia.

5. Shangpin Home

Shangpin Home is a furniture company that emphasizes rapid development relying on high-tech innovation. Over the past eight years, Shangpin Home has always adhered to fashion, taste, and environmental protection. It is committed to creating high-quality homes for every customer.

Word at Last

The above content is the cabinet customization solution provided by Blue Elephant. The cabinet solutions cover all aspects of cabinet production, like cabinet making technology, cabinet machine, cabinet products, cabinet manufacturers, cabinet design, cabinet ideas, and so on. In the next article, Blue Elephant will take you to understand how bathroom furniture is made by using Blue Elephant CNC equipment. If you are interested, please stay tuned.